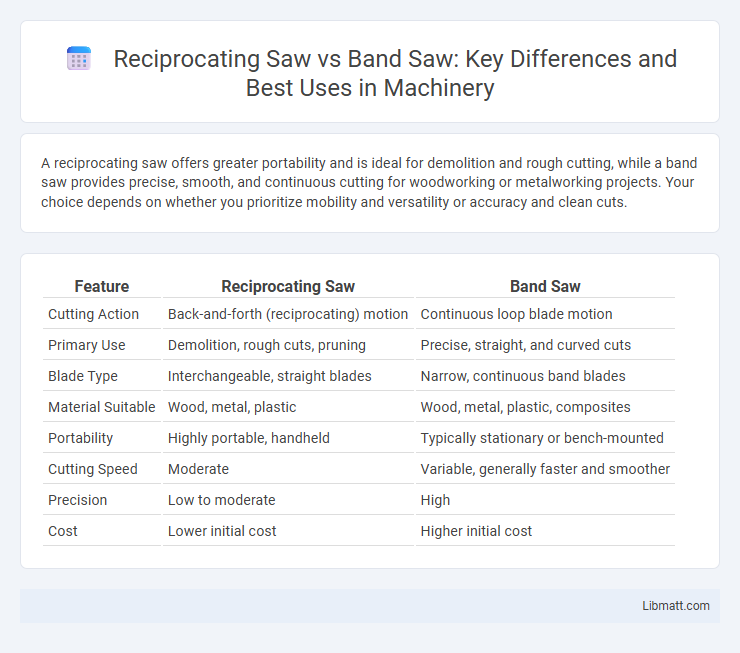

A reciprocating saw offers greater portability and is ideal for demolition and rough cutting, while a band saw provides precise, smooth, and continuous cutting for woodworking or metalworking projects. Your choice depends on whether you prioritize mobility and versatility or accuracy and clean cuts.

Table of Comparison

| Feature | Reciprocating Saw | Band Saw |

|---|---|---|

| Cutting Action | Back-and-forth (reciprocating) motion | Continuous loop blade motion |

| Primary Use | Demolition, rough cuts, pruning | Precise, straight, and curved cuts |

| Blade Type | Interchangeable, straight blades | Narrow, continuous band blades |

| Material Suitable | Wood, metal, plastic | Wood, metal, plastic, composites |

| Portability | Highly portable, handheld | Typically stationary or bench-mounted |

| Cutting Speed | Moderate | Variable, generally faster and smoother |

| Precision | Low to moderate | High |

| Cost | Lower initial cost | Higher initial cost |

Introduction to Reciprocating Saws and Band Saws

Reciprocating saws feature a push-and-pull blade motion ideal for demolition and cutting through wood, metal, and plastic with precision in tight spaces. Band saws utilize a continuous loop blade that delivers smooth, uniform cuts best suited for curved or intricate wood and metal work. Your choice depends on project needs, as reciprocating saws excel in versatility and accessibility, while band saws provide high accuracy and cleaner edges.

Key Differences Between Reciprocating and Band Saws

Reciprocating saws feature a push-and-pull blade motion ideal for demolition and rough cuts, while band saws use a continuous loop blade for precise, smooth cuts in wood, metal, and other materials. Reciprocating saws offer portability and versatility for cutting in tight spaces, whereas band saws excel in stationary setups requiring accurate curves and resawing tasks. Understanding these key differences helps you select the right saw based on your project's precision needs and working environment.

Design and Structure Comparison

A reciprocating saw features a push-and-pull motion with a straight, exposed blade designed for rough cutting and demolition work, while a band saw uses a continuous looped blade tensioned between two wheels for precise, smooth cuts. The compact and handheld design of a reciprocating saw allows for greater maneuverability in tight spaces, whereas the stationary frame of a band saw provides stability and accuracy for detailed wood or metal cutting. Your choice depends on whether you prioritize portability and versatility or precision and control in your cutting tasks.

Cutting Performance: Speed and Precision

Reciprocating saws deliver high-speed, aggressive cuts ideal for demolition and rough materials but sacrifice precision due to their aggressive blade movement. Band saws excel in precision cutting with smooth, continuous blade action, making them perfect for detailed woodworking and metal shaping. Your choice depends on whether speed or exactness is your priority in cutting performance.

Types of Materials Each Saw Can Handle

Reciprocating saws excel at cutting through wood, metal, drywall, and plastic, making them versatile for demolition and rough cutting tasks. Band saws are designed primarily for precise cuts in wood, metal, and plastic, particularly effective with thinner and softer materials or detailed shapes. Choosing the right saw depends on Your project's material type and the required cut accuracy.

Portability and Ease of Use

Reciprocating saws offer superior portability and ease of use due to their compact design and lightweight build, making them ideal for one-handed operation and tight spaces. Band saws are generally larger and require a stationary setup, which limits their mobility but provides greater precision for straight cuts. Your choice should consider whether you need a versatile, portable tool or a stable saw optimized for detailed work.

Common Applications and Best Use Cases

Reciprocating saws excel in demolition work, cutting through wood, metal, and drywall quickly, making them ideal for remodeling and rough cutting tasks. Band saws provide precise and clean cuts suited for woodworking, metal fabrication, and resawing, perfect for detailed and repetitive cuts requiring accuracy. Your choice depends on whether you need aggressive cutting power for tough materials or fine, controlled cuts for precision projects.

Safety Considerations for Both Saws

Reciprocating saws require secure handling to prevent kickback, with users needing to wear protective gloves and eye protection to guard against flying debris and accidental blade contact. Band saws pose risks from exposed blades and pinch points, making the use of blade guards, push sticks, and maintaining proper blade tension essential safety measures. Both tools demand adherence to manufacturer guidelines and regular maintenance to ensure safe operation and minimize injury risks.

Maintenance Requirements and Lifespan

Reciprocating saws require regular blade replacement and lubrication of moving parts to maintain optimal performance, with a typical lifespan of 3 to 5 years depending on usage intensity. Band saws demand consistent blade tensioning, cleaning, and occasional wheel alignment, often lasting 10 to 15 years with proper upkeep. Both tools benefit from routine inspection, but band saws generally offer greater durability and lower long-term maintenance costs.

Choosing the Right Saw for Your Project

When choosing between a reciprocating saw and a band saw for your project, consider the type of cuts and materials involved; reciprocating saws excel in demolition and rough cuts on wood, metal, and plastics, while band saws provide precise, smooth cuts ideal for curved or intricate designs in wood and metal. Reciprocating saws offer portability and versatility for quick, aggressive cutting, whereas band saws require a stationary setup but deliver cleaner, controlled cuts for detailed woodworking or metal fabrication. Evaluating project requirements such as mobility, cut quality, and material thickness will help determine the optimal saw for efficient and accurate results.

Reciprocating saw vs band saw Infographic

libmatt.com

libmatt.com