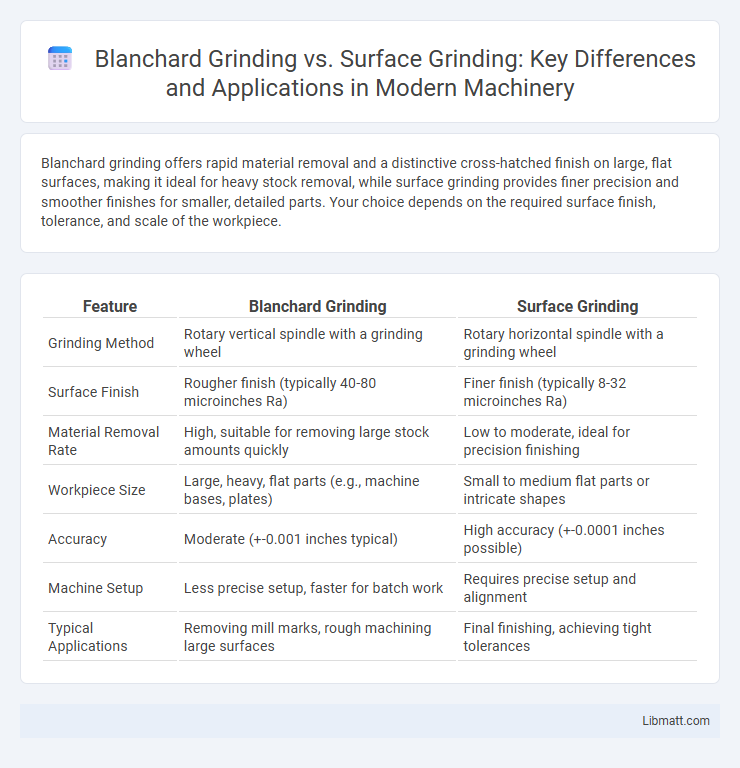

Blanchard grinding offers rapid material removal and a distinctive cross-hatched finish on large, flat surfaces, making it ideal for heavy stock removal, while surface grinding provides finer precision and smoother finishes for smaller, detailed parts. Your choice depends on the required surface finish, tolerance, and scale of the workpiece.

Table of Comparison

| Feature | Blanchard Grinding | Surface Grinding |

|---|---|---|

| Grinding Method | Rotary vertical spindle with a grinding wheel | Rotary horizontal spindle with a grinding wheel |

| Surface Finish | Rougher finish (typically 40-80 microinches Ra) | Finer finish (typically 8-32 microinches Ra) |

| Material Removal Rate | High, suitable for removing large stock amounts quickly | Low to moderate, ideal for precision finishing |

| Workpiece Size | Large, heavy, flat parts (e.g., machine bases, plates) | Small to medium flat parts or intricate shapes |

| Accuracy | Moderate (+-0.001 inches typical) | High accuracy (+-0.0001 inches possible) |

| Machine Setup | Less precise setup, faster for batch work | Requires precise setup and alignment |

| Typical Applications | Removing mill marks, rough machining large surfaces | Final finishing, achieving tight tolerances |

Introduction to Blanchard and Surface Grinding

Blanchard grinding is a rotary surface grinding process that efficiently removes large amounts of material from flat workpieces, providing a consistent and uniform finish with high stock removal rates. Surface grinding, often using a fixed grinding wheel, delivers precise dimensional accuracy and fine surface finishes for smaller or more intricate parts. Both methods utilize abrasive wheels but differ significantly in application, speed, and finish quality, catering to distinct industrial machining requirements.

Core Differences Between Blanchard and Surface Grinding

Blanchard grinding uses a rotary-type grinder with multiple segmented wheels to remove large amounts of material quickly from one side of a workpiece, ideal for heavy stock removal and large surface areas. Surface grinding employs a spinning wheel that moves across the workpiece to achieve finer finishes and precise tolerances on smaller, flatter surfaces. The core differences lie in Blanchard grinding's high material removal rate and coarse finish compared to surface grinding's precision and smooth surface results.

How Blanchard Grinding Works

Blanchard grinding operates by using a rotating horizontal grinding wheel that simultaneously spins and reciprocates over a large, flat workpiece, ensuring rapid material removal and uniform surface finish. The process leverages the wheel's ability to cover a wide area quickly, making it ideal for heavy stock removal on large, flat surfaces. Unlike surface grinding, which typically uses a smaller, stationary wheel with linear movement, Blanchard grinding's unique motion produces characteristic circular cross-hatch patterns and offers faster cycle times for bulk grinding operations.

Surface Grinding Process Overview

Surface grinding is a precision machining process that uses a rotating abrasive wheel to produce a smooth, flat finish on metal or other materials. This method achieves high dimensional accuracy and surface quality by removing fine layers of material from the workpiece's surface. Unlike Blanchard grinding, which involves rotating the workpiece on a vertical spindle, surface grinding typically uses a stationary workpiece and a horizontal wheel, making it ideal for flat or intricate surfaces.

Material Types Suitable for Each Grinding Method

Blanchard grinding is ideal for ferrous materials such as cast iron and steel, offering efficient stock removal on flat surfaces with some tolerance for irregularities. Surface grinding excels with a broader range of materials, including non-ferrous metals like aluminum, brass, and non-metallic substrates, providing high precision and a fine surface finish. Your choice depends on the material type and desired finish, with Blanchard grinding suited for robust, high-volume applications and surface grinding tailored for intricate, precise work on diverse materials.

Advantages of Blanchard Grinding

Blanchard grinding offers superior material removal rates and excellent flatness, making it ideal for large, heavy workpieces requiring quick stock removal. This technique provides consistent surface finish and accuracy due to its indexing mechanism, which enhances productivity and reduces downtime. Your manufacturing process benefits from Blanchard grinding when high-volume, efficient surface preparation is essential.

Benefits of Surface Grinding

Surface grinding offers high precision and superior finish quality, making it ideal for flat surfaces and tight tolerance applications. It enables efficient material removal with consistent dimensional accuracy, enhancing product reliability in aerospace, automotive, and tool manufacturing. The versatility of surface grinding allows processing of various materials, including metals, ceramics, and composites, ensuring broad industrial applicability.

Limitations and Drawbacks of Both Methods

Blanchard grinding faces limitations such as lower surface finish quality compared to surface grinding and is generally unsuitable for precision machining of intricate geometries. Surface grinding, while offering superior precision and finer finishes, struggles with slower material removal rates and higher operational costs due to prolonged cycle times. Both methods encounter constraints related to workpiece size and shape, where extremely large or irregular parts may require alternative machining processes.

Choosing the Right Grinding Process for Your Project

Blanchard grinding offers rapid stock removal on large, flat surfaces, ideal for heavy-duty machining projects requiring high material removal rates. Surface grinding provides finer finishes and tighter tolerances, making it suitable for precision work on smaller or intricate parts. Choosing the right grinding process depends on your project's material removal needs and desired surface quality.

Conclusion: Blanchard vs Surface Grinding Comparison

Blanchard grinding excels in rapid stock removal with its rotary surface, ideal for large, irregularly shaped workpieces, while surface grinding provides superior precision and finish on flatter, smaller parts using a reciprocating motion. Your choice depends on whether efficiency in material removal or finer surface finish and dimensional accuracy are the priorities. Both methods offer distinct advantages, making the decision crucial based on workpiece size, shape, and finish requirements.

Blanchard grinding vs surface grinding Infographic

libmatt.com

libmatt.com