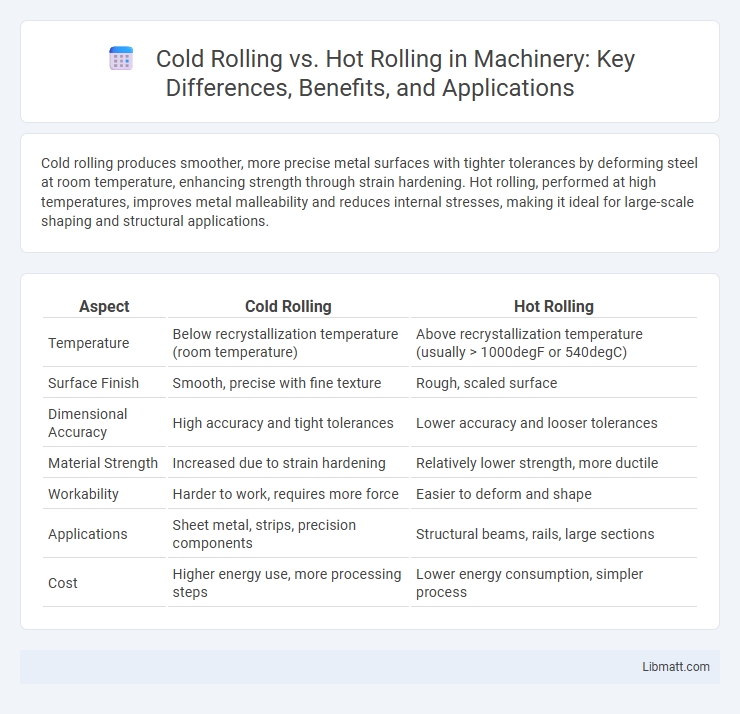

Cold rolling produces smoother, more precise metal surfaces with tighter tolerances by deforming steel at room temperature, enhancing strength through strain hardening. Hot rolling, performed at high temperatures, improves metal malleability and reduces internal stresses, making it ideal for large-scale shaping and structural applications.

Table of Comparison

| Aspect | Cold Rolling | Hot Rolling |

|---|---|---|

| Temperature | Below recrystallization temperature (room temperature) | Above recrystallization temperature (usually > 1000degF or 540degC) |

| Surface Finish | Smooth, precise with fine texture | Rough, scaled surface |

| Dimensional Accuracy | High accuracy and tight tolerances | Lower accuracy and looser tolerances |

| Material Strength | Increased due to strain hardening | Relatively lower strength, more ductile |

| Workability | Harder to work, requires more force | Easier to deform and shape |

| Applications | Sheet metal, strips, precision components | Structural beams, rails, large sections |

| Cost | Higher energy use, more processing steps | Lower energy consumption, simpler process |

Introduction to Metal Rolling Processes

Metal rolling processes involve shaping metal by passing it through rollers to reduce thickness and improve surface finish. Cold rolling occurs below the recrystallization temperature, enhancing strength and surface quality through strain hardening, while hot rolling takes place above this temperature, allowing easier deformation and grain refinement. Each method offers distinct advantages for controlling mechanical properties and dimensional accuracy in metal fabrication.

What is Hot Rolling?

Hot rolling is a metalworking process where steel is heated above its recrystallization temperature, typically above 1,100degF (600degC), allowing it to be shaped and formed easily. This method enhances the material's ductility and reduces internal stresses, resulting in improved workability and toughness. Common applications of hot rolling include producing structural steel shapes, sheets, and plates used in construction and manufacturing industries.

What is Cold Rolling?

Cold rolling is a metalworking process where steel or other metals are passed through rollers at room temperature to reduce thickness and improve surface finish. This method enhances mechanical properties such as strength and hardness by inducing strain hardening without the need for heating. By choosing cold rolling, you achieve precise dimensional control and a superior quality surface ideal for applications requiring tight tolerances.

Key Differences Between Hot and Cold Rolling

Hot rolling and cold rolling are two primary metal forming processes that differ mainly in temperature and resulting material properties. Hot rolling occurs above the metal's recrystallization temperature, producing surfaces with scale and roughness, while cold rolling happens below this temperature, yielding smoother finishes and enhanced strength through strain hardening. You can choose hot rolling for large deformation and improved ductility, while cold rolling is ideal when precision, surface finish, and dimensional accuracy are critical.

Advantages of Hot Rolling

Hot rolling offers significant advantages such as enhanced ductility and improved grain structure, resulting in stronger and more malleable metal products. The process is cost-effective due to lower energy consumption and faster production rates compared to cold rolling. You benefit from better shaping capabilities and reduced need for further processing, making hot rolling ideal for large-scale manufacturing of steel sheets, plates, and structural components.

Advantages of Cold Rolling

Cold rolling enhances metal surface finish and dimensional accuracy compared to hot rolling, resulting in smoother, more precise products. It improves mechanical properties such as strength and hardness through strain hardening, making materials suitable for demanding applications. The process also offers better control over thickness and tight tolerances, reducing the need for further machining or processing.

Applications of Hot Rolled Products

Hot rolled products are widely used in construction, automotive manufacturing, and heavy machinery due to their affordability and ease of shaping. Structural steel beams, rail tracks, and large pipes commonly utilize hot rolled steel for enhanced strength and durability. The process is ideal for applications requiring parts with less precise dimensions but superior toughness and weldability.

Applications of Cold Rolled Products

Cold rolled products are widely used in automotive panels, appliances, and metal furniture due to their superior surface finish and tighter dimensional tolerances. These products also find extensive applications in electrical enclosures, precision instruments, and packaging materials where enhanced strength and improved surface quality are critical. The process of cold rolling improves mechanical properties such as hardness and yield strength, making the products ideal for structural components and decorative purposes.

Factors to Consider When Choosing Rolling Methods

Selecting between cold rolling and hot rolling depends on factors such as the desired mechanical properties, surface finish, and dimensional tolerances. Cold rolling enhances strength and surface smoothness through strain hardening but requires more energy and forces, making it suitable for thinner gauges and precise applications. Hot rolling offers improved ductility and ease of shaping large sections with lower force, ideal for initial shaping and thicker materials but results in scaled surfaces requiring further processing.

Conclusion: Which Rolling Process is Right for Your Needs?

Cold rolling offers superior surface finish, tighter tolerances, and increased strength due to work hardening, making it ideal for precision components and applications requiring high-quality surface aesthetics. Hot rolling, with its ability to process large sections and produce components with improved ductility and toughness, is better suited for structural applications and where dimensional accuracy is less critical. Choosing between cold rolling and hot rolling depends on factors like desired mechanical properties, size and shape requirements, and cost efficiency for your specific manufacturing needs.

Cold rolling vs hot rolling Infographic

libmatt.com

libmatt.com