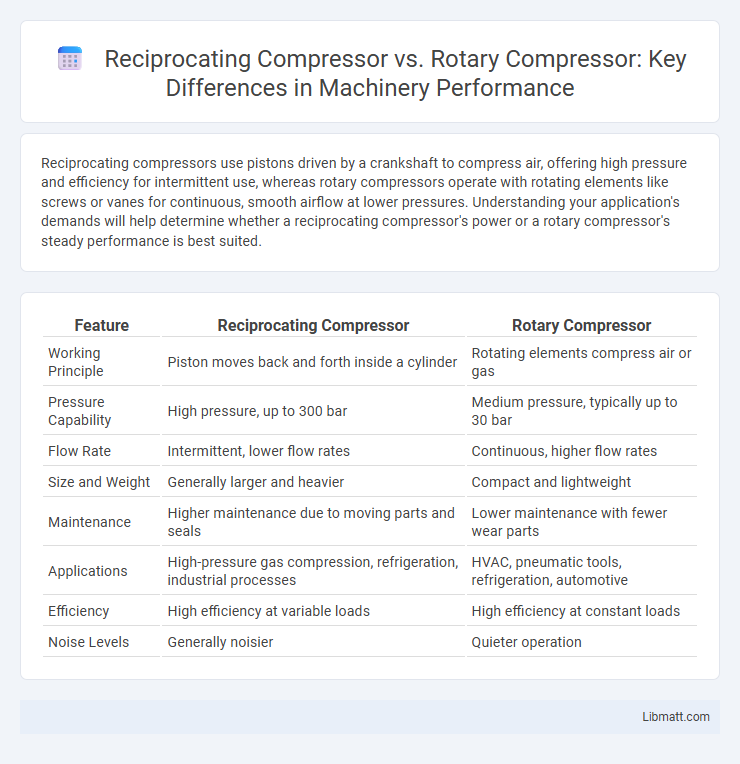

Reciprocating compressors use pistons driven by a crankshaft to compress air, offering high pressure and efficiency for intermittent use, whereas rotary compressors operate with rotating elements like screws or vanes for continuous, smooth airflow at lower pressures. Understanding your application's demands will help determine whether a reciprocating compressor's power or a rotary compressor's steady performance is best suited.

Table of Comparison

| Feature | Reciprocating Compressor | Rotary Compressor |

|---|---|---|

| Working Principle | Piston moves back and forth inside a cylinder | Rotating elements compress air or gas |

| Pressure Capability | High pressure, up to 300 bar | Medium pressure, typically up to 30 bar |

| Flow Rate | Intermittent, lower flow rates | Continuous, higher flow rates |

| Size and Weight | Generally larger and heavier | Compact and lightweight |

| Maintenance | Higher maintenance due to moving parts and seals | Lower maintenance with fewer wear parts |

| Applications | High-pressure gas compression, refrigeration, industrial processes | HVAC, pneumatic tools, refrigeration, automotive |

| Efficiency | High efficiency at variable loads | High efficiency at constant loads |

| Noise Levels | Generally noisier | Quieter operation |

Introduction to Air Compressors

Reciprocating compressors use pistons driven by a crankshaft to compress air in cylinders, providing high-pressure output suitable for industrial and automotive applications. Rotary compressors rely on rotating elements, such as screws or vanes, to continuously compress air, offering smoother operation and higher flow rates for HVAC and manufacturing processes. Understanding your specific air compression needs helps determine whether a reciprocating or rotary compressor best balances efficiency, pressure, and volume for your application.

Overview of Reciprocating Compressors

Reciprocating compressors use pistons driven by a crankshaft to compress gases, making them ideal for high-pressure applications and small to medium volumes. These compressors offer precise control over pressure and flow rates, commonly found in industries such as oil and gas, refrigeration, and manufacturing. Their design enables efficient compression of air or gas with minimal leakage, ensuring reliable performance in demanding environments.

Overview of Rotary Compressors

Rotary compressors use a rotating mechanism, such as a screw, vane, or scroll, to compress gas by continuously reducing volume within a sealed chamber. They offer smooth, steady airflow and are typically more compact and quieter than reciprocating compressors. Commonly found in HVAC systems and refrigeration, rotary compressors provide efficient performance for low to medium pressure applications.

Working Principle: Reciprocating vs Rotary

Reciprocating compressors operate using a piston driven by a crankshaft that moves back and forth within a cylinder to compress gas, creating pressure through a displacement process. Rotary compressors utilize a rotating mechanism, such as screws, vanes, or lobes, to continuously trap and compress gas in a steady flow without pulsation. Your choice between reciprocating and rotary compressors depends on the required pressure, flow rate, and application efficiency, as their working principles impact performance and maintenance.

Efficiency Comparison

Reciprocating compressors typically achieve higher efficiency at lower capacities due to precise volumetric control and reduced leakage, making them ideal for intermittent or variable load applications. Rotary compressors, with fewer moving parts and continuous flow, generally offer better efficiency at higher speeds and steady-state operations, especially in HVAC and refrigeration systems. The overall efficiency comparison depends on specific operational conditions such as pressure ratio, flow rate, and maintenance practices.

Maintenance Requirements

Reciprocating compressors typically demand more frequent maintenance due to their numerous moving parts, such as pistons, valves, and rings, which are prone to wear and require regular inspection and replacement. Rotary compressors, with fewer moving components like rotors and bearings, usually offer lower maintenance requirements and longer service intervals, contributing to reduced downtime and operational costs. Your choice between these compressors should consider the available maintenance resources and the desired reliability for your application.

Performance and Applications

Reciprocating compressors deliver high-pressure output and are ideal for applications requiring precise volume control and intermittent duty, such as gas transmission and refrigeration. Rotary compressors operate efficiently at lower pressures with continuous flow, making them suitable for HVAC systems, air conditioning, and low to medium-pressure industrial processes. Performance-wise, reciprocating compressors offer higher maximum pressures, while rotary compressors provide smoother operation and reduced maintenance.

Cost Considerations

Reciprocating compressors generally have lower initial costs but higher maintenance expenses due to more moving parts and frequent wear. Rotary compressors typically require higher upfront investment yet offer reduced operational costs and longer service intervals, enhancing long-term value. Your choice depends on budget constraints and maintenance capabilities.

Pros and Cons of Each Type

Reciprocating compressors offer high-pressure output and are suitable for small to medium-scale applications but tend to have higher maintenance needs and noise levels due to moving piston parts. Rotary compressors provide continuous airflow with smoother operation, lower noise, and better energy efficiency, yet they may produce lower pressure and are less effective for applications requiring very high pressure. Selecting between reciprocating and rotary compressors depends on specific needs such as pressure requirements, efficiency preferences, and maintenance capacity.

Choosing the Right Compressor for Your Needs

Reciprocating compressors deliver high pressure and are ideal for intermittent, high-demand applications requiring precise control, making them suitable for industries like automotive and manufacturing. Rotary compressors provide continuous airflow with lower noise and maintenance, perfect for HVAC systems and compressors used in refrigeration or air conditioning. Selecting the right compressor depends on factors such as pressure requirements, duty cycle, space constraints, and energy efficiency specific to the intended industrial or commercial application.

Reciprocating compressor vs rotary compressor Infographic

libmatt.com

libmatt.com