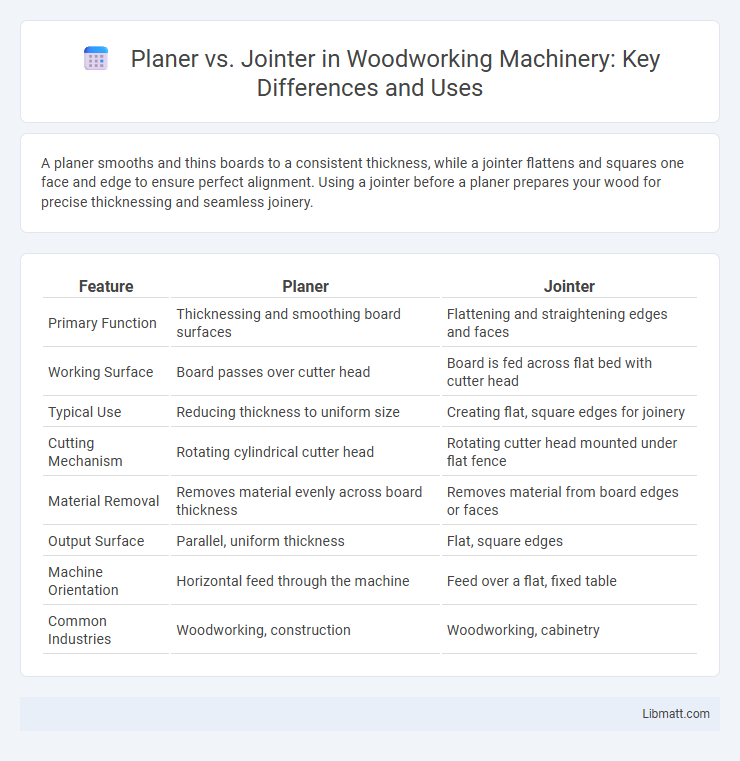

A planer smooths and thins boards to a consistent thickness, while a jointer flattens and squares one face and edge to ensure perfect alignment. Using a jointer before a planer prepares your wood for precise thicknessing and seamless joinery.

Table of Comparison

| Feature | Planer | Jointer |

|---|---|---|

| Primary Function | Thicknessing and smoothing board surfaces | Flattening and straightening edges and faces |

| Working Surface | Board passes over cutter head | Board is fed across flat bed with cutter head |

| Typical Use | Reducing thickness to uniform size | Creating flat, square edges for joinery |

| Cutting Mechanism | Rotating cylindrical cutter head | Rotating cutter head mounted under flat fence |

| Material Removal | Removes material evenly across board thickness | Removes material from board edges or faces |

| Output Surface | Parallel, uniform thickness | Flat, square edges |

| Machine Orientation | Horizontal feed through the machine | Feed over a flat, fixed table |

| Common Industries | Woodworking, construction | Woodworking, cabinetry |

Introduction to Planers and Jointers

Planers and jointers are essential woodworking machines designed for surface smoothing and dimensioning. A planer primarily reduces the thickness of a board by shaving the surface uniformly, ensuring consistent thickness throughout the length of the wood. In contrast, a jointer is used to create flat edges and straighten boards, making it ideal for preparing wood for edge joining and achieving precise 90-degree angles.

Key Differences Between Planers and Jointers

Planers and jointers serve distinct functions in woodworking: planers primarily thickness boards to uniform dimensions, while jointers create flat, square edges for precise edge joining. A planer has a set of rotating blades beneath a flat bed to shave the surface, whereas a jointer features an adjustable fence and cutter head to flatten and straighten edges. Understanding these key differences is essential for woodworkers aiming for accurate board preparation and seamless assembly.

How a Planer Works

A planer works by feeding a wooden board through spinning blades that shave off the surface to achieve a uniform thickness and smooth finish. The adjustable cutting depth allows precise control over the amount of material removed, ensuring consistent results across the entire board length. This tool is essential for dimensioning rough lumber, flattening both sides parallel for woodworking projects.

How a Jointer Works

A jointer works by flattening and straightening the face or edge of a wooden board using rotating knives mounted on a cutter head. As your wood passes over the jointer's flat, adjustable table, the cutting blades remove high spots and create a smooth, even surface essential for precise joinery. This process prepares your lumber for further planing or assembly, ensuring accurate and crisp edges for seamless wood projects.

Common Uses for Planers

Planers are primarily used for smoothing and flattening rough lumber, reducing board thickness, and creating uniform surfaces for woodworking projects. Your ability to achieve precise thickness control and remove imperfections makes planers essential for preparing raw wood before assembly or finishing. Common applications include dimensioning reclaimed wood, refining rough-sawn timber, and ensuring consistent die-cut edges for cabinetry or furniture making.

Common Uses for Jointers

Jointers are primarily used to flatten and straighten the edges of boards, creating a smooth, straight surface that is essential for accurate gluing and jointing. Your woodworking projects benefit from jointers when preparing rough lumber, ensuring perfectly square edges for seamless assembly. Common uses include edge jointing boards before gluing, face jointing boards to remove twists or warps, and achieving precise 90-degree edges for cabinet and furniture making.

Choosing Between a Planer and a Jointer

Choosing between a planer and a jointer depends on your woodworking needs: a jointer is ideal for flattening and squaring the edges of boards, while a planer is designed to create uniform thickness across the entire board surface. If your projects require smooth, flat faces and perfectly squared edges, your best option might be to use both tools in tandem for optimal results. Understanding the unique functions of each tool ensures you achieve precision and quality in your woodworking tasks.

Pros and Cons of Planers

Planers excel at thicknessing boards quickly and creating uniform thickness, making them ideal for preparing rough lumber. They can produce clean, flat surfaces but may struggle with heavily cupped or twisted wood, often requiring a jointer beforehand for optimal results. Planers are less effective at flattening one face of a board, which is a significant limitation compared to jointers, leading to potential unevenness if used alone.

Pros and Cons of Jointers

Jointers provide a precise method for flattening one face of a board and squaring an edge, essential for preparing rough lumber for further processing. They excel at removing twists and warps, ensuring straight edges for edge joining, but their limited width capacity can restrict the size of boards they handle. However, jointers require careful setup and can produce more waste compared to planers, which are better suited for thinning boards to a uniform thickness.

Planer vs Jointer: Which Tool Do You Need?

Planers and jointers serve different purposes in woodworking: a planer smooths and thicknesses boards to uniform dimensions, while a jointer flattens one face and squares edges for precise joints. Choosing the right tool depends on whether your primary need is thicknessing rough lumber or achieving perfectly flat and square surfaces for assembly. Woodworkers often use both tools in sequence to ensure dimensionally accurate and flat stock before further processing or finishing.

Planer vs jointer Infographic

libmatt.com

libmatt.com