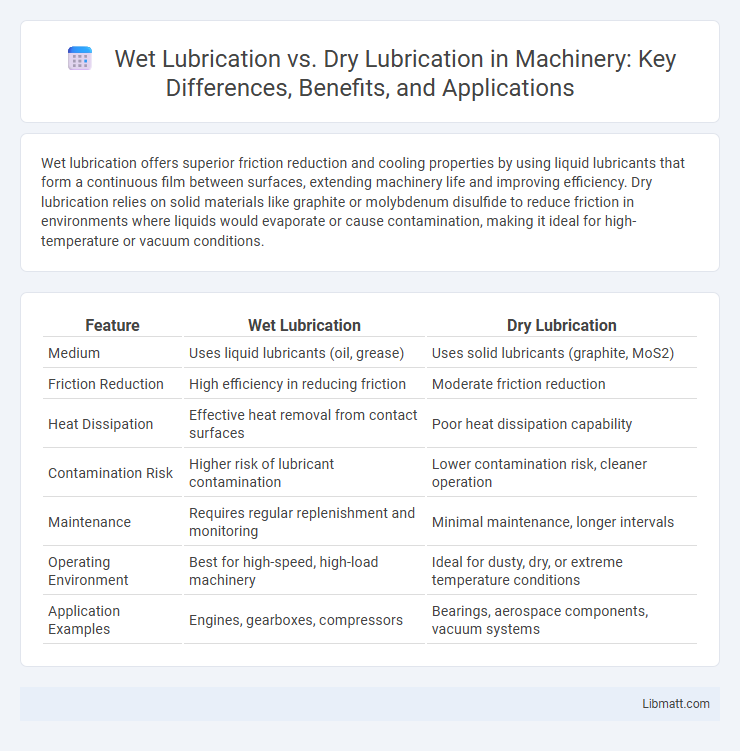

Wet lubrication offers superior friction reduction and cooling properties by using liquid lubricants that form a continuous film between surfaces, extending machinery life and improving efficiency. Dry lubrication relies on solid materials like graphite or molybdenum disulfide to reduce friction in environments where liquids would evaporate or cause contamination, making it ideal for high-temperature or vacuum conditions.

Table of Comparison

| Feature | Wet Lubrication | Dry Lubrication |

|---|---|---|

| Medium | Uses liquid lubricants (oil, grease) | Uses solid lubricants (graphite, MoS2) |

| Friction Reduction | High efficiency in reducing friction | Moderate friction reduction |

| Heat Dissipation | Effective heat removal from contact surfaces | Poor heat dissipation capability |

| Contamination Risk | Higher risk of lubricant contamination | Lower contamination risk, cleaner operation |

| Maintenance | Requires regular replenishment and monitoring | Minimal maintenance, longer intervals |

| Operating Environment | Best for high-speed, high-load machinery | Ideal for dusty, dry, or extreme temperature conditions |

| Application Examples | Engines, gearboxes, compressors | Bearings, aerospace components, vacuum systems |

Introduction to Lubrication Methods

Wet lubrication utilizes a liquid lubricant, such as oil, to create a continuous film between moving parts, reducing friction and wear effectively in high-load or high-speed applications. Dry lubrication employs solid lubricants like graphite or molybdenum disulfide, offering low friction without the risk of contamination or fluid leakage, making it ideal for extreme temperatures or vacuum environments. Your choice between wet and dry lubrication depends on operating conditions, maintenance requirements, and environmental factors to optimize machinery performance.

Defining Wet Lubrication

Wet lubrication involves the application of a liquid lubricant, such as oil or grease, between moving surfaces to reduce friction and wear. This method forms a continuous film that prevents direct metal-to-metal contact, enhancing machine efficiency and longevity. Common in automotive engines and industrial machinery, wet lubrication also helps dissipate heat and protect against corrosion.

Understanding Dry Lubrication

Dry lubrication involves applying solid lubricants such as graphite, molybdenum disulfide, or PTFE to reduce friction and wear between surfaces without the use of liquid oils or greases. It is highly effective in environments where wet lubricants may evaporate, freeze, or attract contaminants, making it ideal for high-temperature, vacuum, or cleanroom applications. Dry lubricants form a protective, low-friction film that maintains performance under extreme pressure and prevents metal-to-metal contact.

Key Differences Between Wet and Dry Lubrication

Wet lubrication involves using liquid lubricants, such as oils or greases, which provide a continuous film that reduces friction and dissipates heat effectively across contact surfaces. Dry lubrication uses solid lubricants like graphite or molybdenum disulfide, ideal for applications where liquid contamination is a concern or extreme temperatures prevail. Key differences include the medium used, with wet lubrication offering superior cooling and wetting capabilities, while dry lubrication excels in environments requiring low maintenance and resistance to washout or evaporation.

Advantages of Wet Lubrication

Wet lubrication offers superior cooling and contamination removal, enhancing the longevity and efficiency of mechanical components. It provides a continuous lubricant film that reduces friction and wear more effectively than dry lubrication. Your machinery benefits from improved performance in high-load and high-speed applications due to the consistent presence of liquid lubricant.

Benefits of Dry Lubrication

Dry lubrication offers benefits such as reduced contamination and maintenance requirements compared to wet lubrication, making it ideal for environments where cleanliness is critical. It provides long-lasting friction reduction without fluid leakage, which enhances the performance and lifespan of machinery components. Additionally, dry lubricants improve energy efficiency by minimizing drag and are compatible with extreme temperature and pressure conditions.

Typical Applications of Wet Lubrication

Wet lubrication is predominantly used in heavy machinery, automotive engines, and industrial gear systems where continuous lubrication is essential to reduce friction and wear under high loads and temperatures. Typical applications include internal combustion engines, hydraulic systems, and rolling element bearings that require consistent oil films to maintain performance and prevent metal-to-metal contact. This lubrication method excels in environments needing efficient heat dissipation and contamination removal, ensuring longevity and reliability in mechanical components.

Common Uses for Dry Lubrication

Dry lubrication is commonly used in applications where traditional wet lubricants pose contamination risks, such as in food processing, electronics, and cleanroom environments. It is preferred in high-temperature or vacuum conditions where liquid lubricants would evaporate or degrade. Examples include aerospace components, precision instruments, and conveyor systems where minimal friction without residue is critical.

Factors to Consider When Choosing Lubrication Type

Choosing between wet and dry lubrication depends on factors such as operating temperature, load conditions, and environmental exposure. Wet lubrication offers superior cooling and wear protection in high-load or high-speed applications, while dry lubrication excels in clean, dust-sensitive environments where contamination must be minimized. Material compatibility, maintenance intervals, and cost-effectiveness also influence the selection to optimize equipment performance and longevity.

Conclusion: Selecting the Right Lubrication Solution

Choosing the right lubrication solution depends on the specific application environment, operating conditions, and maintenance requirements. Wet lubrication offers superior cooling and minimizes friction in high-speed or heavy-load machinery, while dry lubrication excels in extreme temperatures and dusty environments where wet lubricants can attract contaminants. Your decision should balance performance, durability, and cost-effectiveness to optimize equipment reliability and lifespan.

Wet lubrication vs dry lubrication Infographic

libmatt.com

libmatt.com