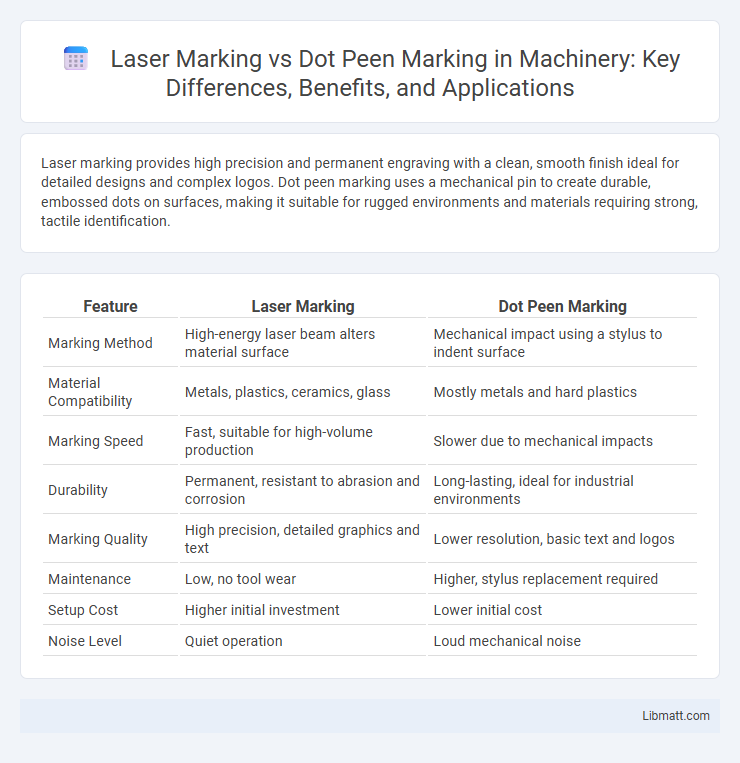

Laser marking provides high precision and permanent engraving with a clean, smooth finish ideal for detailed designs and complex logos. Dot peen marking uses a mechanical pin to create durable, embossed dots on surfaces, making it suitable for rugged environments and materials requiring strong, tactile identification.

Table of Comparison

| Feature | Laser Marking | Dot Peen Marking |

|---|---|---|

| Marking Method | High-energy laser beam alters material surface | Mechanical impact using a stylus to indent surface |

| Material Compatibility | Metals, plastics, ceramics, glass | Mostly metals and hard plastics |

| Marking Speed | Fast, suitable for high-volume production | Slower due to mechanical impacts |

| Durability | Permanent, resistant to abrasion and corrosion | Long-lasting, ideal for industrial environments |

| Marking Quality | High precision, detailed graphics and text | Lower resolution, basic text and logos |

| Maintenance | Low, no tool wear | Higher, stylus replacement required |

| Setup Cost | Higher initial investment | Lower initial cost |

| Noise Level | Quiet operation | Loud mechanical noise |

Introduction to Industrial Marking Technologies

Laser marking offers high precision and permanent marks on various materials using focused light beams, ideal for detailed logos and barcodes. Dot peen marking employs a stylus to create a series of small indentations, providing durable and legible marks on metals and hard surfaces. Both technologies are essential in industrial settings for traceability, product identification, and compliance with manufacturing standards.

Understanding Laser Marking: How It Works

Laser marking uses a focused beam of light to create precise, permanent marks on a variety of materials by altering their surface properties without physical contact. This process heats the material to either evaporate, discolor, or engrave the surface, resulting in high-resolution, corrosion-resistant marks ideal for traceability. Your choice of laser marking ensures detailed, clean labels that withstand harsh environments compared to the mechanical impact of dot peen marking.

Dot Peen Marking: Principles and Applications

Dot peen marking utilizes a stylus to create a series of small indents or dots on metal surfaces, forming permanent and highly legible marks through mechanical impact. This method excels in industrial applications where durability and resistance to harsh conditions are critical, such as automotive parts, aerospace components, and heavy machinery serial numbers. Your choice of dot peen marking ensures precise, long-lasting identification even on curved or irregular surfaces, making it ideal for traceability in demanding environments.

Comparing Marking Speed: Laser vs Dot Peen

Laser marking offers significantly faster marking speeds compared to dot peen marking, with rates reaching up to several meters per second depending on the material and laser type. Dot peen marking operates at slower speeds due to its mechanical impact process, often making it less suitable for high-volume production environments. Your choice between the two should consider the required marking speed alongside material compatibility and desired mark precision.

Marking Quality and Precision: A Side-by-Side Analysis

Laser marking delivers superior marking quality and precision by producing clean, high-resolution graphics with minimal material distortion, making it ideal for fine details and complex designs. Dot peen marking creates indented marks through a series of dots, offering durable but less refined results, which may lack the sharpness and clarity of laser marks. Your choice depends on the requirement for intricate detail and surface finish, with laser marking excelling in accuracy and visual appeal compared to the more rugged dot peen method.

Material Compatibility: Laser vs Dot Peen Marking

Laser marking offers superior material compatibility, effectively marking metals, plastics, ceramics, and glass with high precision and minimal surface damage. Dot peen marking primarily suits metals and harder plastics, delivering deep, durable marks ideal for rugged applications but with limited effectiveness on softer or reflective materials. The choice depends on application requirements, considering material type, marking depth, and finish quality.

Durability and Longevity of Markings

Laser marking offers superior durability and longevity compared to dot peen marking, as it creates precise, permanent marks by altering the material's surface through heat without physical abrasion. The absence of mechanical impact reduces the risk of wear and fading, making laser marks ideal for high-wear environments requiring long-lasting identification. Dot peen marking, while cost-effective, produces shallow indentations prone to corrosion and erosion, which can diminish readability over time under harsh conditions.

Cost Comparison: Initial Investment and Maintenance

Laser marking requires a higher initial investment, often ranging from $15,000 to over $100,000 depending on the system's complexity, while dot peen marking systems typically start around $5,000 to $20,000. Maintenance costs for laser markers are generally lower due to fewer moving parts and less wear, whereas dot peen machines incur higher ongoing expenses related to consumable pins and mechanical repairs. Total cost of ownership favors laser marking in high-volume or precision applications despite its upfront expense, whereas dot peen provides a cost-effective solution for lower-volume or rugged environments.

Safety and Environmental Considerations

Laser marking offers a contactless process that reduces workplace hazards by minimizing dust and debris, while dot peen marking involves mechanical impact that generates noise and particulate matter requiring protective measures. Laser systems typically consume less energy and produce no consumable waste, making them environmentally friendly compared to the metal pins used and replaced in dot peen marking. Your choice should consider workplace safety protocols, noise regulations, and environmental impact to ensure compliance and sustainability.

Choosing the Right Marking Method for Your Needs

Laser marking offers high precision and permanent, clean markings ideal for intricate designs and delicate materials, while dot peen marking excels in durability on rough or metal surfaces requiring deep, tactile marks. Your choice hinges on factors like material type, required permanence, and detail level, with laser marking preferred for fine, detailed work and dot peen for robust, industrial applications. Evaluate production volume and operating environment to determine the most efficient, cost-effective marking solution tailored to your specific requirements.

Laser marking vs dot peen marking Infographic

libmatt.com

libmatt.com