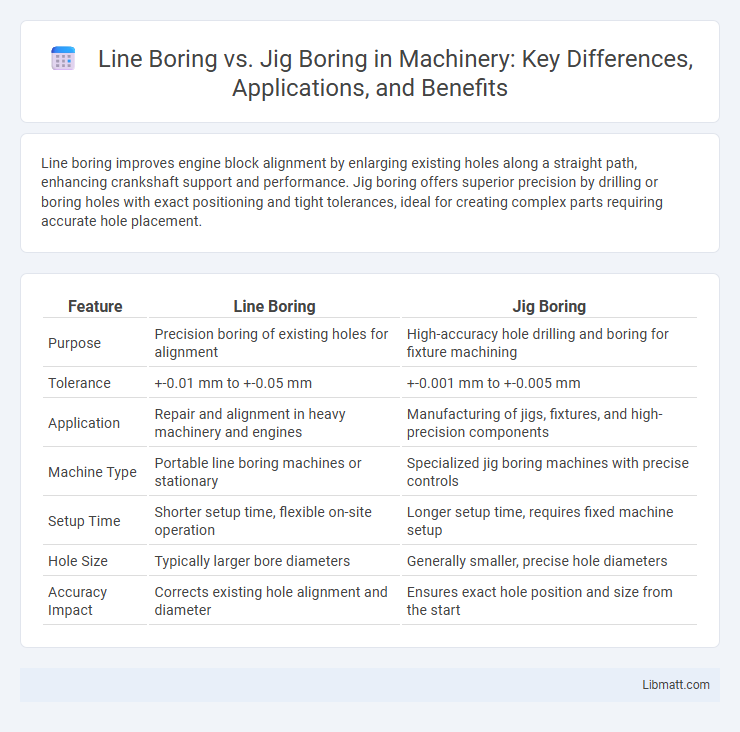

Line boring improves engine block alignment by enlarging existing holes along a straight path, enhancing crankshaft support and performance. Jig boring offers superior precision by drilling or boring holes with exact positioning and tight tolerances, ideal for creating complex parts requiring accurate hole placement.

Table of Comparison

| Feature | Line Boring | Jig Boring |

|---|---|---|

| Purpose | Precision boring of existing holes for alignment | High-accuracy hole drilling and boring for fixture machining |

| Tolerance | +-0.01 mm to +-0.05 mm | +-0.001 mm to +-0.005 mm |

| Application | Repair and alignment in heavy machinery and engines | Manufacturing of jigs, fixtures, and high-precision components |

| Machine Type | Portable line boring machines or stationary | Specialized jig boring machines with precise controls |

| Setup Time | Shorter setup time, flexible on-site operation | Longer setup time, requires fixed machine setup |

| Hole Size | Typically larger bore diameters | Generally smaller, precise hole diameters |

| Accuracy Impact | Corrects existing hole alignment and diameter | Ensures exact hole position and size from the start |

Introduction to Line Boring and Jig Boring

Line boring is a precision machining process used to enlarge or restore the internal diameter of a cylindrical hole, typically in engine blocks or heavy machinery components, ensuring accurate alignment and smooth surfaces. Jig boring focuses on creating highly accurate holes and machining positions in metal parts by using a jig or fixture for precise location control, making it ideal for tooling and die applications requiring tight tolerances. Both methods emphasize precision, but line boring primarily restores or refines existing holes, while jig boring establishes new, exact hole patterns.

Definition and Core Principles

Line boring is a machining process that enlarges or restores the diameter of an existing hole using a rigid boring bar to ensure precise alignment along an axis. Jig boring is a highly accurate machining technique designed to create precise hole locations and sizes with tight tolerances, employing a specialized jig boring machine for exceptional positional accuracy. You can choose line boring for repairing or resizing cylindrical bores, while jig boring suits applications demanding precise hole placement and finish.

Key Differences Between Line Boring and Jig Boring

Line boring primarily focuses on machining cylindrical surfaces to restore alignment in engine blocks and heavy machinery, using long boring bars to achieve precise diameters over extended distances. Jig boring offers higher positional accuracy and surface finish quality, utilizing advanced coordinate measuring machines to drill or bore holes with precise location control for tooling and molds. The key differences lie in their application scope--line boring corrects worn or misaligned bores in large components, while jig boring is essential for creating highly accurate, repeatable hole patterns in precision engineering.

Applications of Line Boring

Line boring is primarily used to repair or enlarge existing holes in heavy machinery such as engine blocks, construction equipment, and industrial machinery, ensuring precise alignment and smooth operation. Its applications extend to refurbishing cylinder bores, crankshaft bores, and bearing housings where maintaining tight tolerances and structural integrity is critical. Your choice of line boring can significantly improve machinery lifespan by restoring worn or damaged components with high accuracy.

Applications of Jig Boring

Jig boring is primarily used in applications requiring highly accurate hole placement and fine precision, such as in the manufacture of precision tools, dies, and molds. It is ideal for producing multiple holes with exact spacing and alignment, often in aerospace and automotive industries where tight tolerances are crucial. The process excels in machining complex components needing meticulous surface finishes and dimensional accuracy.

Accuracy and Precision Comparison

Line boring offers high precision in machining large diameter holes, typically achieving tolerances around +-0.01 mm, making it ideal for repair and alignment tasks on heavy machinery. Jig boring surpasses line boring in accuracy, with tolerances often reaching +-0.005 mm or better, suitable for creating precise holes in complex jigs and fixtures. While line boring focuses on restoring existing parts with moderate precision, jig boring excels in manufacturing new components requiring superior accuracy and repeatability.

Equipment and Tooling Requirements

Line boring requires heavy-duty equipment such as portable boring machines designed for machining large engine blocks or heavy industrial components, often utilizing single-point cutting tools and specialized boring heads for cylindrical accuracy. Jig boring demands precision jig borers equipped with fine feed controls, high-accuracy spindle bearings, and interchangeable tool heads to achieve exact hole locations and tight tolerances in toolmaking and die work. Your choice between line boring and jig boring should consider the scale and precision of the task, as jig boring emphasizes meticulous positional accuracy while line boring focuses on restoring cylindrical alignment over large workpieces.

Advantages of Line Boring

Line boring offers precise, consistent boring of engine blocks or machinery components, ensuring accurate alignment and minimal wear. This method is highly efficient for repairing or refurbishing large cylindrical surfaces, reducing downtime and labor costs. You benefit from improved machine performance and extended equipment life due to the enhanced accuracy and smoothness achieved by line boring.

Advantages of Jig Boring

Jig boring offers unparalleled precision and accuracy, making it ideal for producing highly detailed components with tight tolerances. This process excels at machining complex shapes and ensures consistent repeatability, which significantly reduces the need for secondary finishing operations. Your manufacturing efficiency improves when choosing jig boring for tasks requiring exact hole placement and alignment.

Choosing the Right Method for Your Project

Choosing the right method for your project depends on the precision and scope required; line boring offers efficient, large-scale repair for engine blocks and machinery, while jig boring provides ultra-precise hole positioning ideal for toolmaking and aerospace components. Understanding your project's tolerance levels and component size helps determine whether the controlled, high-accuracy capabilities of jig boring or the cost-effective, larger diameter machining of line boring is more suitable. You can optimize manufacturing outcomes by matching the method to your specific dimensional and alignment needs.

Line boring vs jig boring Infographic

libmatt.com

libmatt.com