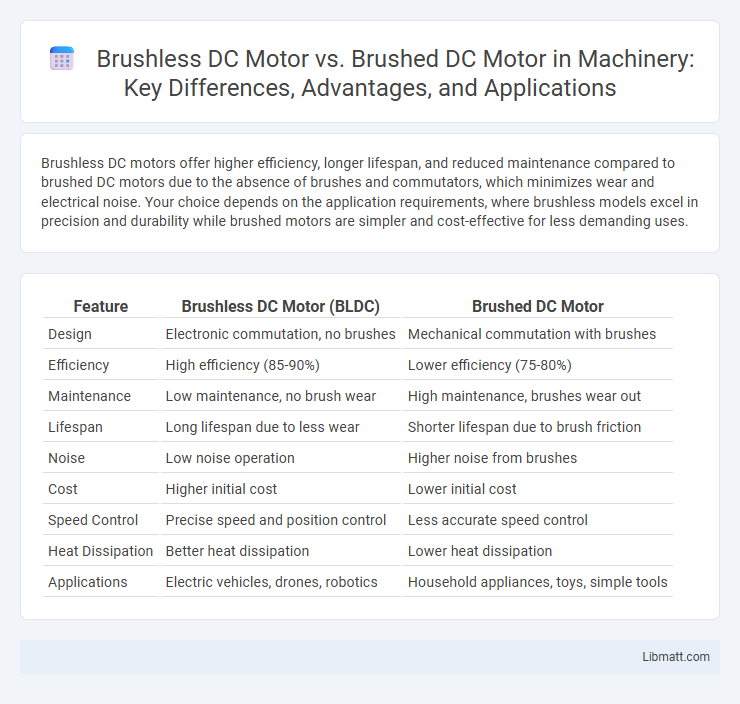

Brushless DC motors offer higher efficiency, longer lifespan, and reduced maintenance compared to brushed DC motors due to the absence of brushes and commutators, which minimizes wear and electrical noise. Your choice depends on the application requirements, where brushless models excel in precision and durability while brushed motors are simpler and cost-effective for less demanding uses.

Table of Comparison

| Feature | Brushless DC Motor (BLDC) | Brushed DC Motor |

|---|---|---|

| Design | Electronic commutation, no brushes | Mechanical commutation with brushes |

| Efficiency | High efficiency (85-90%) | Lower efficiency (75-80%) |

| Maintenance | Low maintenance, no brush wear | High maintenance, brushes wear out |

| Lifespan | Long lifespan due to less wear | Shorter lifespan due to brush friction |

| Noise | Low noise operation | Higher noise from brushes |

| Cost | Higher initial cost | Lower initial cost |

| Speed Control | Precise speed and position control | Less accurate speed control |

| Heat Dissipation | Better heat dissipation | Lower heat dissipation |

| Applications | Electric vehicles, drones, robotics | Household appliances, toys, simple tools |

Introduction to DC Motors

Brushless DC motors offer higher efficiency, longer lifespan, and reduced maintenance compared to brushed DC motors due to the absence of brushes and commutators. Brushed DC motors use carbon brushes to deliver current to the rotor windings, causing wear and limiting durability. You can improve performance and reliability by choosing a brushless DC motor for applications requiring consistent torque and precise speed control.

What is a Brushed DC Motor?

A brushed DC motor operates using brushes and a commutator to deliver current to the motor windings, creating torque through electromagnetic interactions. This design allows for simple control and cost-effective manufacturing but results in higher wear and maintenance due to brush friction. Brushed motors typically have lower efficiency and reduced lifespan compared to brushless DC motors, making them suitable for applications where cost and simplicity are prioritized over durability.

What is a Brushless DC Motor?

A brushless DC motor (BLDC) operates without brushes, using electronic commutation to control the current through the motor windings, resulting in higher efficiency and reduced maintenance compared to brushed DC motors. Unlike brushed motors, BLDC motors rely on a permanent magnet rotor and a stator with electronically switched coils, which enhances durability and performance in applications requiring precision and longevity. Your choice of a brushless DC motor ensures quieter operation, better speed control, and longer lifespan, making it ideal for modern electric vehicles, drones, and industrial machinery.

Key Differences Between Brushed and Brushless DC Motors

Brushless DC motors use electronic commutation to eliminate brushes, resulting in higher efficiency, reduced maintenance, and longer lifespan compared to brushed DC motors, which rely on mechanical brushes and commutators. Brushless motors offer better speed control, quieter operation, and increased reliability, while brushed motors tend to be simpler and less expensive but suffer from wear and electrical noise. The absence of brushes in brushless motors significantly minimizes friction and heat generation, making them ideal for high-performance applications.

Efficiency Comparison: Brushed vs Brushless

Brushless DC motors offer significantly higher efficiency than brushed DC motors due to reduced energy loss from friction and electrical resistance. Without brushes causing mechanical drag and sparking, brushless motors convert more electrical power into mechanical output, enhancing performance and lifespan. Optimizing Your system with a brushless motor can lead to energy savings and improved reliability in demanding applications.

Maintenance Requirements

Brushless DC motors require significantly less maintenance compared to brushed DC motors due to the absence of brushes that wear out over time. Your operational costs decrease as brushless motors eliminate the need for regular brush replacements and reduce downtime. This makes brushless DC motors ideal for applications demanding high reliability and long service life.

Lifespan and Durability

Brushless DC motors exhibit significantly longer lifespan and higher durability compared to brushed DC motors due to the absence of brushes, which eliminates wear and reduces maintenance requirements. The sealed design of brushless motors also protects internal components from dust and contaminants, further enhancing durability. In contrast, brushed DC motors experience brush and commutator wear, limiting their operational lifespan and necessitating periodic replacement and servicing.

Performance and Control

Brushless DC motors offer superior performance with higher efficiency, increased lifespan, and smoother operation due to the absence of brushes, enabling precise speed and torque control through electronic commutation. In contrast, brushed DC motors rely on mechanical brushes and commutators that cause wear and decrease reliability, limiting control flexibility and efficiency. Advanced control algorithms in brushless motors allow for improved responsiveness and reduced maintenance in dynamic applications.

Cost Analysis and Applications

Brushless DC motors (BLDC) typically have higher initial costs due to complex electronic controllers and manufacturing processes compared to brushed DC motors, which are cheaper and simpler to produce. BLDC motors offer superior efficiency, reliability, and low maintenance, making them ideal for electric vehicles, drones, and industrial automation, while brushed motors are preferred in applications requiring low cost and simpler control, such as toys and household appliances. Cost analysis favors brushed motors for budget-sensitive projects, whereas BLDC motors deliver better long-term value through enhanced performance and durability in demanding environments.

Choosing the Right DC Motor for Your Needs

Brushless DC motors offer higher efficiency, longer lifespan, and lower maintenance compared to brushed DC motors, which are simpler and more cost-effective for basic applications. Your choice depends on factors such as speed control precision, durability requirements, and budget constraints. For applications demanding reliability and quiet operation, brushless DC motors are ideal, while brushed motors suit simpler, low-cost scenarios.

Brushless DC motor vs brushed DC motor Infographic

libmatt.com

libmatt.com