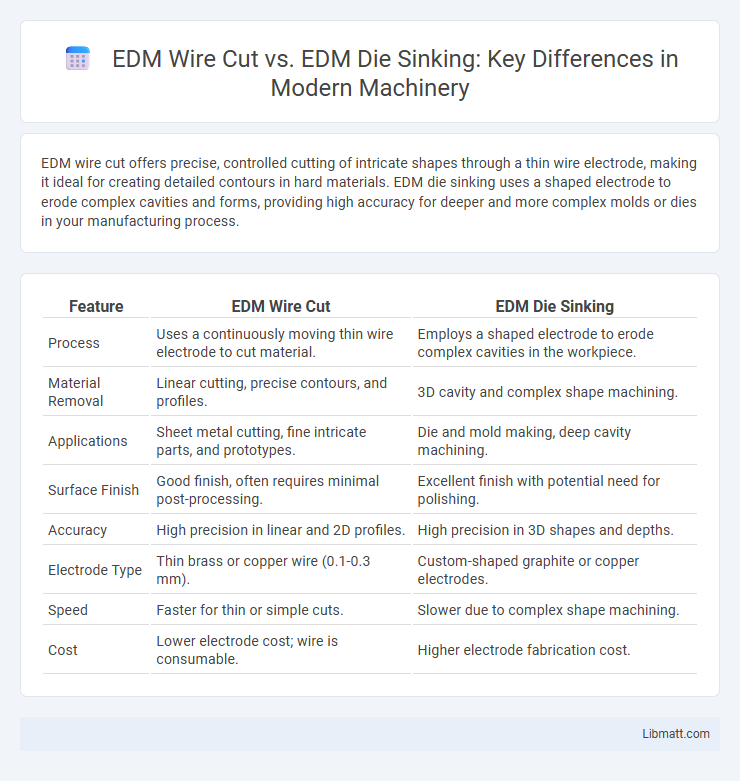

EDM wire cut offers precise, controlled cutting of intricate shapes through a thin wire electrode, making it ideal for creating detailed contours in hard materials. EDM die sinking uses a shaped electrode to erode complex cavities and forms, providing high accuracy for deeper and more complex molds or dies in your manufacturing process.

Table of Comparison

| Feature | EDM Wire Cut | EDM Die Sinking |

|---|---|---|

| Process | Uses a continuously moving thin wire electrode to cut material. | Employs a shaped electrode to erode complex cavities in the workpiece. |

| Material Removal | Linear cutting, precise contours, and profiles. | 3D cavity and complex shape machining. |

| Applications | Sheet metal cutting, fine intricate parts, and prototypes. | Die and mold making, deep cavity machining. |

| Surface Finish | Good finish, often requires minimal post-processing. | Excellent finish with potential need for polishing. |

| Accuracy | High precision in linear and 2D profiles. | High precision in 3D shapes and depths. |

| Electrode Type | Thin brass or copper wire (0.1-0.3 mm). | Custom-shaped graphite or copper electrodes. |

| Speed | Faster for thin or simple cuts. | Slower due to complex shape machining. |

| Cost | Lower electrode cost; wire is consumable. | Higher electrode fabrication cost. |

Introduction to EDM Wire Cut and EDM Die Sinking

EDM Wire Cut uses a continuously moving thin wire as an electrode to erode metal and create complex shapes with high precision, making it ideal for cutting intricate contours and thin sections. EDM Die Sinking employs a custom-shaped electrode that is lowered into the workpiece to erode cavities or patterns, excelling in producing 3D molds and dies with detailed surface finishes. Your choice between these methods depends on the complexity and shape of the part you need to manufacture.

Fundamental Principles of EDM Wire Cut

EDM Wire Cut operates by using a thin, electrically charged wire to precisely erode metal through controlled sparks, maintaining tight tolerances and minimal material distortion. This method suits complex contours and fine details, providing high accuracy in cutting conductive materials without direct mechanical contact. The process relies on continuous flushing of dielectric fluid to remove debris and ensure consistent spark generation for optimal surface finish.

Key Concepts Behind EDM Die Sinking

EDM die sinking utilizes a shaped electrode to erode complex cavity forms with high precision, relying on controlled electrical discharges between the electrode and workpiece. This method excels in producing intricate dies and molds with fine surface finishes and dimensional accuracy. Die sinking is especially effective for hard metals and detailed internal geometries that are difficult to machine using traditional techniques.

Differences in Cutting Techniques

EDM wire cut uses a thin, electrically charged wire to accurately slice through metal with minimal material waste, ideal for intricate shapes and fine details. EDM die sinking employs a shaped electrode that erodes metal by repeated pulses to create cavities or complex molds in harder materials. Your choice between the two depends on the precision required and the geometry of the workpiece, as wire cut excels in thin cuts while die sinking is better for deep, three-dimensional features.

Material Compatibility and Applications

EDM wire cut excels in machining hard conductive materials like tool steel and titanium alloys with high precision, making it ideal for intricate shapes and fine detail in aerospace and automotive components. EDM die sinking targets both conductive and some semi-conductive materials, especially suited for creating complex cavities and molds in industries such as plastic injection molding and die making. Your choice depends on the material hardness, complexity of the design, and specific application requirements to achieve optimal results.

Surface Finish and Precision Comparison

EDM wire cut offers superior precision with tolerances often within +-0.005 mm, ideal for intricate contours and sharp corners, whereas EDM die sinking provides slightly less accuracy, typically within +-0.01 mm. Surface finish in wire cut EDM generally achieves Ra values around 0.4 to 1.6 micrometers, making it suitable for fine finishes without extensive post-processing. EDM die sinking delivers rougher surfaces, ranging from Ra 1.6 to 3.2 micrometers, requiring additional polishing for high-quality finishes.

Process Speed and Efficiency

EDM wire cut machines typically offer faster processing speeds due to continuous wire movement and efficient cooling, making them ideal for cutting intricate shapes with high precision. EDM die sinking tends to be slower as it uses a shaped electrode to erode material layer by layer, which can result in longer cycle times for complex geometries. Wire EDM excels in efficiency for thin or detailed parts, whereas die sinking is more suited for deeper cavities and complex 3D contours despite its slower speed.

Cost Implications of Each Method

EDM wire cut generally incurs higher operational costs due to slower cutting speeds and increased consumable wire expenses, making it less economical for large volume production. EDM die sinking offers cost efficiency for complex shapes and intricate designs by using graphite or copper electrodes, which reduce machining time and tooling costs. Considering tooling durability and material waste, EDM die sinking tends to deliver better overall cost control for high-precision mold and die manufacturing.

Advantages and Limitations

EDM wire cut offers high precision and intricate contouring ideal for thin materials and complex shapes, with minimal heat-affected zones, but it is generally slower and less effective for thicker or hardened materials. EDM die sinking excels in machining hard metals and producing complex cavities with deep cuts, providing faster material removal rates, yet it requires electrode fabrication and may introduce more heat distortion. Selecting between EDM wire cut and die sinking depends on factors like material thickness, part complexity, and surface finish requirements.

Choosing the Right EDM Process for Your Project

Selecting the appropriate EDM process depends on project specifications such as material thickness, precision, and complexity. EDM wire cut excels in producing intricate 2D profiles and fine tolerances on thin to medium-thickness metals, making it ideal for detailed component cutting. EDM die sinking offers high precision for complex 3D shapes and deep cavities, suitable for molds, dies, and components requiring detailed surface finishes.

EDM wire cut vs EDM die sinking Infographic

libmatt.com

libmatt.com