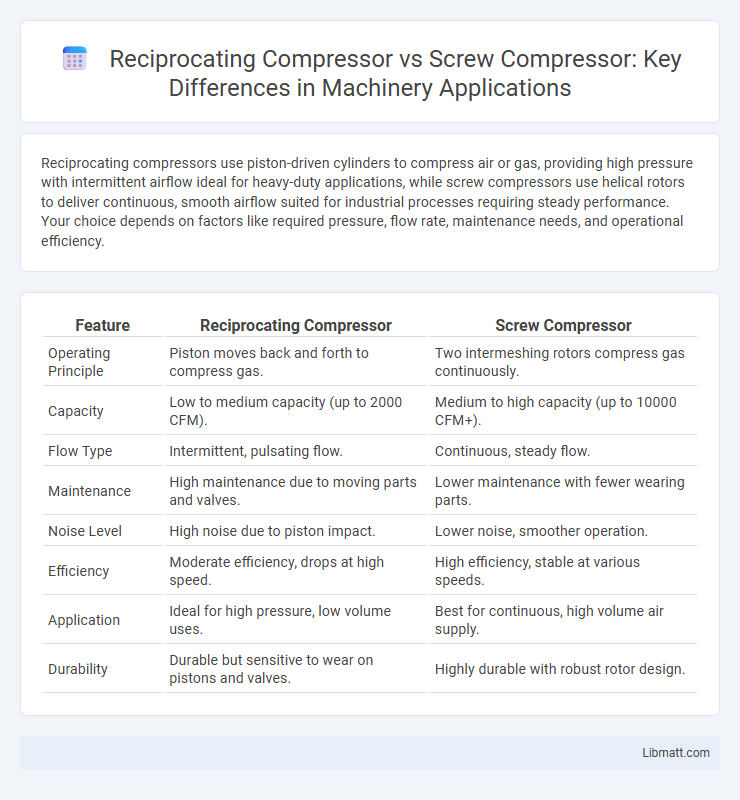

Reciprocating compressors use piston-driven cylinders to compress air or gas, providing high pressure with intermittent airflow ideal for heavy-duty applications, while screw compressors use helical rotors to deliver continuous, smooth airflow suited for industrial processes requiring steady performance. Your choice depends on factors like required pressure, flow rate, maintenance needs, and operational efficiency.

Table of Comparison

| Feature | Reciprocating Compressor | Screw Compressor |

|---|---|---|

| Operating Principle | Piston moves back and forth to compress gas. | Two intermeshing rotors compress gas continuously. |

| Capacity | Low to medium capacity (up to 2000 CFM). | Medium to high capacity (up to 10000 CFM+). |

| Flow Type | Intermittent, pulsating flow. | Continuous, steady flow. |

| Maintenance | High maintenance due to moving parts and valves. | Lower maintenance with fewer wearing parts. |

| Noise Level | High noise due to piston impact. | Lower noise, smoother operation. |

| Efficiency | Moderate efficiency, drops at high speed. | High efficiency, stable at various speeds. |

| Application | Ideal for high pressure, low volume uses. | Best for continuous, high volume air supply. |

| Durability | Durable but sensitive to wear on pistons and valves. | Highly durable with robust rotor design. |

Introduction to Reciprocating and Screw Compressors

Reciprocating compressors use pistons driven by a crankshaft to compress gas in a cylinder, offering high pressure output and suitability for low flow rates. Screw compressors employ two meshing helical rotors to continuously compress gas, providing smooth, steady flow ideal for high volume applications. Both types are essential in industrial settings, with reciprocating compressors excelling in high-pressure tasks and screw compressors favored for efficiency in large-scale operations.

Working Principle of Reciprocating Compressors

Reciprocating compressors operate by using a piston driven by a crankshaft to compress gas within a cylinder through a back-and-forth motion. This mechanical process results in high-pressure delivery suitable for applications requiring intermittent or variable flow rates. Your choice between reciprocating and screw compressors should consider the piston's ability to handle high-pressure conditions efficiently.

Working Principle of Screw Compressors

Screw compressors operate using two interlocking helical rotors that compress air by reducing the volume as the rotors turn, generating continuous and smooth flow of compressed gas. Unlike reciprocating compressors that use pistons and cylinders for compression, screw compressors provide higher efficiency and less vibration in industrial applications. Your choice of a screw compressor ensures reliable performance with lower maintenance due to fewer moving parts and consistent pressure output.

Key Differences Between Reciprocating and Screw Compressors

Reciprocating compressors utilize pistons driven by a crankshaft to compress gas in discrete strokes, making them ideal for high-pressure, low-flow applications. Screw compressors employ meshing helical rotors to provide continuous, smooth airflow, suited for large volume and lower pressure needs. Your choice depends on factors like maintenance frequency, noise tolerance, and efficiency requirements in specific industrial settings.

Energy Efficiency Comparison

Reciprocating compressors generally offer higher efficiency at lower capacities and intermittent operation due to their positive displacement mechanism, while screw compressors provide superior energy efficiency for continuous, high-capacity applications because of their rotary design and smooth airflow. Your choice between these compressors should consider operational load, as screw compressors maintain consistent efficiency in variable loads, reducing energy consumption and operational costs over time. Energy savings can be significant with screw compressors in industrial settings demanding steady airflow, whereas reciprocating compressors perform best in applications requiring precise, variable output.

Maintenance and Operational Costs

Reciprocating compressors generally incur higher maintenance costs due to their numerous moving parts, frequent lubrication requirements, and potential for piston ring and valve replacement. Screw compressors, with fewer moving components and continuous operation capability, typically offer lower maintenance expenses and reduced downtime, resulting in more cost-effective long-term operation. Your choice between the two should consider the balance between initial investment and ongoing operational efficiency to optimize overall expenses.

Applications and Industry Uses

Reciprocating compressors excel in high-pressure, low-flow applications such as refrigeration, natural gas processing, and petrochemical industries due to their ability to deliver precise pressure control. Screw compressors are favored in continuous, high-capacity operations found in manufacturing plants, HVAC systems, and food processing industries, offering reliable performance with lower vibration and maintenance needs. Both compressor types serve critical roles across oil and gas, chemical processing, and industrial manufacturing sectors, chosen based on specific pressure, flow, and operational requirements.

Noise Levels and Vibration

Reciprocating compressors typically generate higher noise levels and vibrations due to their piston-driven mechanism, resulting in more mechanical impact and intermittent pressure pulses. Screw compressors operate with continuous rotary motion, producing significantly lower noise and smoother vibration profiles, making them ideal for noise-sensitive environments. Effective vibration isolation and noise dampening are critical for reciprocating units to reduce operational disturbances and maintenance issues.

Pros and Cons of Reciprocating Compressors

Reciprocating compressors offer high pressure output and precise capacity control, making them ideal for applications requiring variable flow and intermittent use. They are durable and cost-effective for smaller scale operations but tend to be bulky, noisy, and require frequent maintenance compared to screw compressors. Your choice depends on the balance between efficiency, maintenance needs, and the specific pressure and flow requirements of your system.

Pros and Cons of Screw Compressors

Screw compressors offer higher efficiency and continuous operation with fewer vibration issues compared to reciprocating compressors, making them ideal for large industrial applications. They have a simpler design with fewer moving parts, which reduces maintenance requirements and increases reliability, but they typically come with higher upfront costs and lower pressure capability. Your choice depends on balancing the need for smooth, steady airflow with budget constraints and specific pressure demands.

Reciprocating compressor vs screw compressor Infographic

libmatt.com

libmatt.com