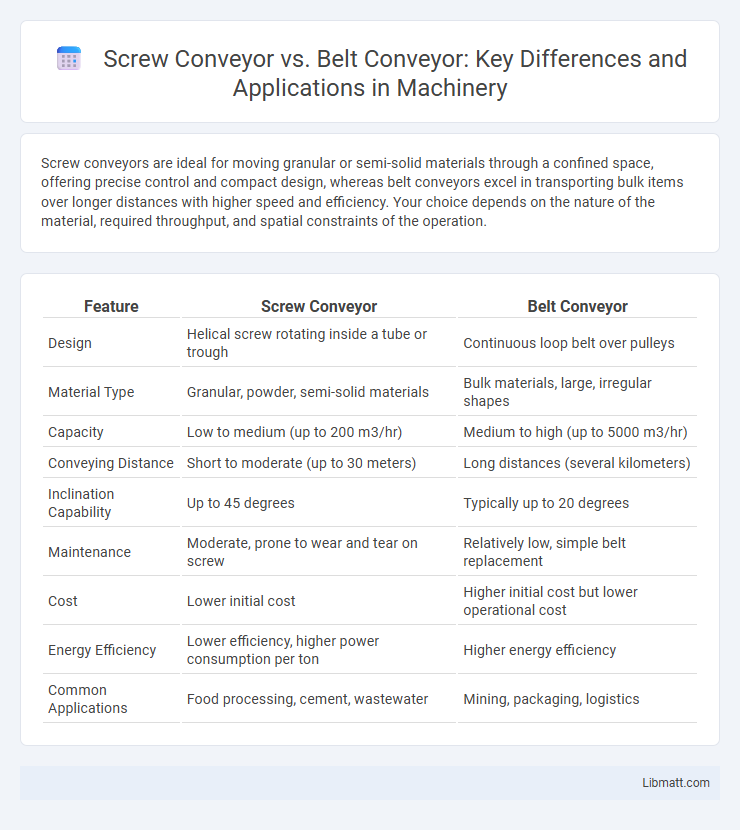

Screw conveyors are ideal for moving granular or semi-solid materials through a confined space, offering precise control and compact design, whereas belt conveyors excel in transporting bulk items over longer distances with higher speed and efficiency. Your choice depends on the nature of the material, required throughput, and spatial constraints of the operation.

Table of Comparison

| Feature | Screw Conveyor | Belt Conveyor |

|---|---|---|

| Design | Helical screw rotating inside a tube or trough | Continuous loop belt over pulleys |

| Material Type | Granular, powder, semi-solid materials | Bulk materials, large, irregular shapes |

| Capacity | Low to medium (up to 200 m3/hr) | Medium to high (up to 5000 m3/hr) |

| Conveying Distance | Short to moderate (up to 30 meters) | Long distances (several kilometers) |

| Inclination Capability | Up to 45 degrees | Typically up to 20 degrees |

| Maintenance | Moderate, prone to wear and tear on screw | Relatively low, simple belt replacement |

| Cost | Lower initial cost | Higher initial cost but lower operational cost |

| Energy Efficiency | Lower efficiency, higher power consumption per ton | Higher energy efficiency |

| Common Applications | Food processing, cement, wastewater | Mining, packaging, logistics |

Introduction to Screw Conveyors and Belt Conveyors

Screw conveyors use a rotating helical screw blade to move bulk materials through a trough, ideal for handling granular or semi-solid substances in confined spaces. Belt conveyors consist of a continuous belt loop powered by pulleys, efficiently transporting materials over longer distances with smooth and consistent flow. Your choice depends on factors such as material type, distance, and the specific requirements of your material handling application.

Working Principles of Screw Conveyors vs Belt Conveyors

Screw conveyors operate by rotating a helical screw blade within a tube to move bulk materials along the trough, providing precise control over the flow rate and handling abrasive or sticky substances efficiently. Belt conveyors use a continuous loop of material, such as rubber or fabric, driven by pulleys to transport items over longer distances with smooth, consistent motion ideal for bulk or unit loads. The fundamental difference in working principles lies in the screw conveyor's rotary motion for incremental material displacement versus the belt conveyor's linear motion for continuous material transport.

Key Components and Construction Differences

Screw conveyors consist of a helical screw blade housed in a tubular or U-shaped trough, enabling efficient material movement through rotational motion, while belt conveyors utilize a continuous loop of a flexible belt supported by rollers or a flat slide. Key components of screw conveyors include the screw shaft, trough, and end bearings, designed for handling bulk solids in compact spaces, whereas belt conveyors feature pulleys, idlers, and a motorized drive system optimized for transporting larger volumes over longer distances. Construction differences highlight the enclosed design of screw conveyors that minimize spillage and dust, contrasted with the open, versatile configuration of belt conveyors suited for diverse materials and inclined transport.

Material Handling Capabilities

Screw conveyors excel in handling semi-solid materials, powders, and granular substances, especially in confined spaces and inclined or vertical transport scenarios. Belt conveyors are more efficient for moving bulkier, heavier, or fragile materials over longer distances with minimal degradation and consistent flow rates. Material-specific factors such as moisture content, particle size, and abrasiveness significantly influence the optimal choice between screw and belt conveyors for industrial applications.

Space and Installation Requirements

Screw conveyors occupy less horizontal space and are ideal for compact installations due to their vertical or inclined configurations. Belt conveyors require more floor space because of their length and horizontal orientation, but they offer easier access for maintenance and cleaning. Installation complexity for screw conveyors increases with system length and material characteristics, while belt conveyors demand a stable, level surface and more extensive structural support.

Energy Efficiency Comparison

Screw conveyors typically consume more energy than belt conveyors due to higher friction and mechanical resistance in moving materials through a rotating helical screw. Belt conveyors operate with lower friction, resulting in more efficient energy use, especially over longer distances and for bulk materials. Energy consumption for screw conveyors increases significantly with material load and conveyor length, whereas belt conveyors maintain relatively consistent efficiency regardless of these factors.

Maintenance and Operational Costs

Screw conveyors typically require more frequent maintenance due to wear on the screw flight and potential for material buildup, increasing operational costs over time. Belt conveyors demand regular belt tension adjustments and occasional belt replacements, but generally offer lower maintenance expenses and energy consumption. Selecting between the two depends on application-specific factors such as material type, environment, and throughput requirements.

Applications and Industry Suitability

Screw conveyors excel in handling bulk materials like grains, cement, and chemicals in industries such as agriculture, construction, and wastewater treatment. Belt conveyors are ideal for transporting heavy loads over longer distances and are widely used in mining, manufacturing, and packaging sectors. Your choice depends on the material type, transfer distance, and industry requirements for efficient and reliable material handling.

Advantages and Limitations of Each Conveyor Type

Screw conveyors excel in handling bulk materials with limited horizontal space, offering precise metering and suitability for abrasive or corrosive substances, but they have limitations in length and are less efficient for high-capacity transport. Belt conveyors provide high capacity and long-distance transport with smooth handling of various materials, making them ideal for continuous operations, yet they require more maintenance and are less effective for inclined or sticky materials. Understanding the advantages and limitations of each can help you select the best conveyor type for your specific industrial application.

Choosing the Right Conveyor for Your Application

Screw conveyors excel in handling bulk solids with precise metering and are ideal for short-distance, inclined, or confined space applications, especially with granular or powder materials. Belt conveyors offer higher capacities and greater transport distances, making them suitable for moving large volumes of uniform or mixed loads horizontally or on gentle inclines. Selecting the right conveyor depends on material characteristics, required throughput, installation space, and operational environment to optimize efficiency and maintenance costs.

Screw conveyor vs belt conveyor Infographic

libmatt.com

libmatt.com