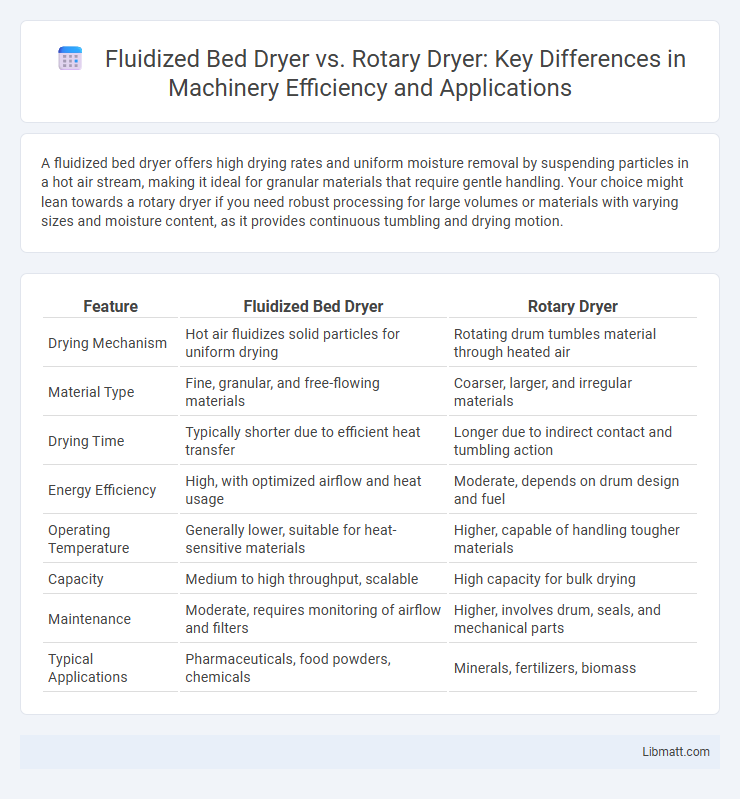

A fluidized bed dryer offers high drying rates and uniform moisture removal by suspending particles in a hot air stream, making it ideal for granular materials that require gentle handling. Your choice might lean towards a rotary dryer if you need robust processing for large volumes or materials with varying sizes and moisture content, as it provides continuous tumbling and drying motion.

Table of Comparison

| Feature | Fluidized Bed Dryer | Rotary Dryer |

|---|---|---|

| Drying Mechanism | Hot air fluidizes solid particles for uniform drying | Rotating drum tumbles material through heated air |

| Material Type | Fine, granular, and free-flowing materials | Coarser, larger, and irregular materials |

| Drying Time | Typically shorter due to efficient heat transfer | Longer due to indirect contact and tumbling action |

| Energy Efficiency | High, with optimized airflow and heat usage | Moderate, depends on drum design and fuel |

| Operating Temperature | Generally lower, suitable for heat-sensitive materials | Higher, capable of handling tougher materials |

| Capacity | Medium to high throughput, scalable | High capacity for bulk drying |

| Maintenance | Moderate, requires monitoring of airflow and filters | Higher, involves drum, seals, and mechanical parts |

| Typical Applications | Pharmaceuticals, food powders, chemicals | Minerals, fertilizers, biomass |

Introduction to Industrial Dryers

Industrial dryers like fluidized bed dryers and rotary dryers play a crucial role in material processing by efficiently removing moisture from bulk solids. Fluidized bed dryers excel in drying fine, granular materials through intense air-solid contact, while rotary dryers are versatile for handling large volumes of varied particle sizes with continuous rotation. Your choice hinges on factors like material characteristics, drying time, energy consumption, and operational costs to optimize drying performance.

Overview of Fluidized Bed Dryers

Fluidized bed dryers utilize a high-velocity gas stream to suspend and dry particulate materials, enabling rapid and uniform moisture removal. They are highly efficient for drying powders, granules, and crystals due to enhanced heat and mass transfer rates compared to rotary dryers. Commonly applied in chemical, pharmaceutical, and food industries, fluidized bed dryers offer precise temperature control and reduced drying times.

Overview of Rotary Dryers

Rotary dryers are robust, cylindrical drums that rotate to evenly dry bulk solids through direct or indirect heat exchange, commonly used in industries like mining, chemicals, and food processing. Their design allows uniform drying with high thermal efficiency and the capacity to handle large volumes of materials with varying moisture contents. You can optimize drying by adjusting rotation speed, drum slope, and air flow, making rotary dryers suitable for heavy-duty, continuous drying operations.

Working Principles Compared

A fluidized bed dryer operates by suspending solid particles in a heated air stream, creating a fluid-like state that enhances heat and mass transfer for uniform drying. In contrast, a rotary dryer uses a rotating drum to tumble materials while hot air passes through, promoting moisture evaporation by continuous agitation. Your choice depends on the material type and drying efficiency required, as fluidized bed dryers excel in drying small, granular materials with higher uniformity, whereas rotary dryers handle larger, coarse materials with robust throughput.

Key Performance Differences

Fluidized bed dryers offer uniform drying through enhanced particle fluidization, resulting in faster moisture removal and consistent product quality compared to rotary dryers. Rotary dryers function by tumbling material in a rotating drum, which is effective for larger, coarse particles but often leads to uneven drying and longer processing times. Energy efficiency favors fluidized bed dryers due to better heat transfer rates, while rotary dryers are more versatile for handling a wide range of material sizes and moisture contents.

Energy Efficiency Analysis

Fluidized bed dryers generally offer higher energy efficiency compared to rotary dryers due to improved heat transfer and shorter drying times. The fluidized bed design enhances contact between hot air and material, reducing energy consumption per unit of moisture removed. Your choice of dryer impacts operational costs significantly, with fluidized bed dryers often providing lower energy expenditures in industrial drying processes.

Material Suitability and Flexibility

Fluidized bed dryers excel in drying fine, granular, and heat-sensitive materials due to their uniform air distribution and gentle handling, making them ideal for pharmaceuticals, food powders, and chemicals. Rotary dryers offer greater flexibility in processing a wide range of bulk materials, including coarse, sticky, or fibrous solids, by adjusting drum speed and heat input to accommodate varying moisture contents. Selecting between these dryers depends on the material's particle size, thermal sensitivity, and production scale, with fluidized beds favoring uniformity and rotary units providing adaptability.

Maintenance and Operational Considerations

Fluidized bed dryers require regular inspection of the air distribution system and filters to maintain optimal airflow and prevent clogging, while rotary dryers demand consistent monitoring of drum seals and internal flights to avoid wear and tear. Operationally, fluidized bed dryers excel in quick drying times and uniform heat transfer, but may involve higher energy consumption due to increased airflow requirements, whereas rotary dryers offer robust handling of large, coarse particles with lower maintenance frequency, though they typically require longer drying cycles. Your choice between these two should consider ease of maintenance access, operational efficiency, and the specific characteristics of the material being processed.

Cost Comparison: Fluidized Bed vs Rotary Dryers

Fluidized bed dryers generally offer lower operational costs due to faster drying times and better heat transfer efficiency compared to rotary dryers, which often require higher energy input and longer processing duration. Initial capital investment for fluidized bed dryers can be higher, but maintenance expenses tend to be lower because of fewer moving parts and simplified design. Your choice of dryer should consider long-term energy savings and maintenance costs, with fluidized bed dryers providing cost advantages especially in large-scale, continuous drying applications.

Conclusion: Selecting the Right Dryer

Selecting the right dryer depends on the specific material characteristics and production requirements; fluidized bed dryers offer superior heat transfer and uniform drying ideal for granules and powders with good fluidization properties. Rotary dryers provide versatility for a wide range of materials, including large particles and heat-sensitive products, due to their gentle tumbling action and ability to handle high moisture content. Evaluating factors like drying time, energy efficiency, product integrity, and capacity is crucial for optimizing drying performance and cost-effectiveness.

Fluidized bed dryer vs rotary dryer Infographic

libmatt.com

libmatt.com