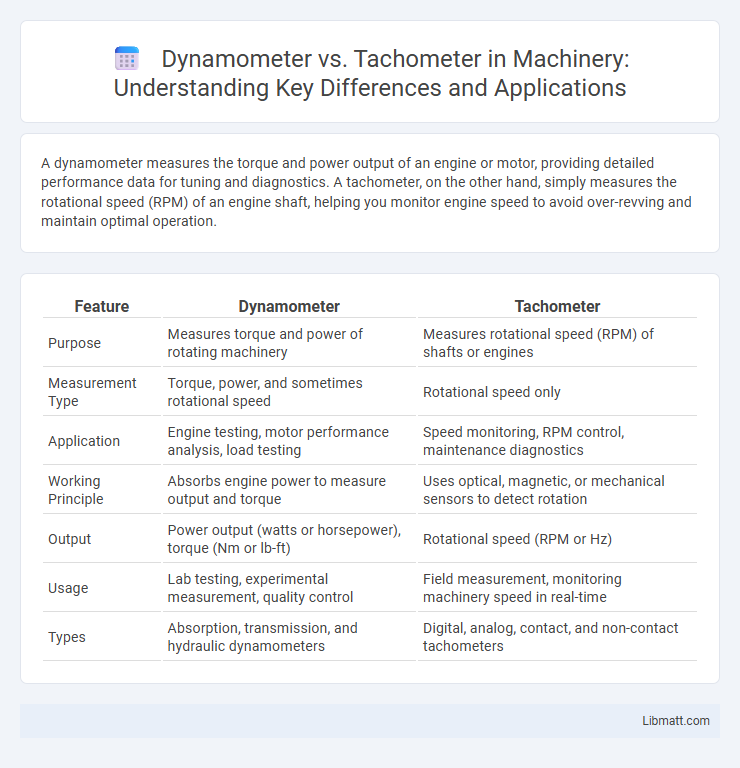

A dynamometer measures the torque and power output of an engine or motor, providing detailed performance data for tuning and diagnostics. A tachometer, on the other hand, simply measures the rotational speed (RPM) of an engine shaft, helping you monitor engine speed to avoid over-revving and maintain optimal operation.

Table of Comparison

| Feature | Dynamometer | Tachometer |

|---|---|---|

| Purpose | Measures torque and power of rotating machinery | Measures rotational speed (RPM) of shafts or engines |

| Measurement Type | Torque, power, and sometimes rotational speed | Rotational speed only |

| Application | Engine testing, motor performance analysis, load testing | Speed monitoring, RPM control, maintenance diagnostics |

| Working Principle | Absorbs engine power to measure output and torque | Uses optical, magnetic, or mechanical sensors to detect rotation |

| Output | Power output (watts or horsepower), torque (Nm or lb-ft) | Rotational speed (RPM or Hz) |

| Usage | Lab testing, experimental measurement, quality control | Field measurement, monitoring machinery speed in real-time |

| Types | Absorption, transmission, and hydraulic dynamometers | Digital, analog, contact, and non-contact tachometers |

Introduction to Dynamometers and Tachometers

Dynamometers measure torque and power output of engines or motors by applying controlled resistance, providing critical data for performance testing and tuning. Tachometers measure rotational speed in revolutions per minute (RPM), offering real-time feedback on engine or machine speed for operational control and monitoring. Both instruments are essential in automotive, aerospace, and industrial applications to optimize mechanical efficiency and reliability.

Definition and Core Functions

A dynamometer measures torque, power, and rotational speed to assess engine or motor performance under various loads. A tachometer exclusively measures rotational speed, typically in revolutions per minute (RPM), providing real-time engine or shaft speed data. While both instruments monitor rotational parameters, the dynamometer offers comprehensive performance analysis, whereas the tachometer focuses solely on speed measurement.

Key Differences Between Dynamometers and Tachometers

Dynamometers measure the torque, power, and rotational force of an engine or motor, providing comprehensive performance data, while tachometers solely measure the rotational speed, typically in revolutions per minute (RPM). You rely on dynamometers for detailed diagnostics and tuning processes, whereas tachometers are used for monitoring engine speed in real-time applications. The key difference is that dynamometers offer a broader analysis of mechanical output compared to the tachometer's specific speed measurement functionality.

Types of Dynamometers

Dynamometers come in various types, including absorption, which measures power by absorbing energy from the engine or motor, and transmission, which analyzes power output through the drive shaft. Another common type is the hydraulic dynamometer, utilizing fluid resistance to determine torque and rotational speed, while eddy current dynamometers employ electromagnetic forces for precise load application. Selecting the right dynamometer type depends on your application requirements, such as accuracy, load capacity, and the nature of the rotational measurement compared to simpler tachometers that solely record RPM.

Types of Tachometers

Tachometers come in various types, including mechanical, analog, and digital, each designed to measure rotational speed in revolutions per minute (RPM) with different levels of accuracy and application. Optical tachometers use light beams to detect rotation, while contact tachometers rely on physical contact with the rotating object. Magnetic and laser tachometers offer non-contact, high-precision speed measurement suited for industrial and automotive diagnostics.

Applications in Automotive Testing

Dynamometers measure engine power and torque, providing crucial data for tuning and performance evaluation in automotive testing. Tachometers track engine RPM, essential for monitoring speed and ensuring optimal operation during diagnostics. Your choice between these instruments depends on whether you need detailed power output analysis or real-time rotational speed feedback.

Accuracy and Measurement Parameters

A dynamometer provides precise measurements of torque, power, and rotational speed, offering comprehensive data on engine or motor performance, while a tachometer primarily measures rotational speed with less detail on mechanical output. Dynamometers excel in accuracy for load-dependent parameters, making them ideal for performance testing and calibration, whereas tachometers deliver quick and straightforward RPM readings with moderate accuracy. Your choice depends on whether you require detailed performance metrics or simple rotational speed monitoring.

Advantages and Limitations of Each Device

A dynamometer accurately measures torque and power output, making it essential for performance testing but requires complex setup and can be costly. A tachometer provides precise rotational speed data, offering simplicity and cost-effectiveness but lacks direct torque measurement. Your choice depends on whether you prioritize comprehensive engine diagnostics or straightforward RPM monitoring.

Choosing the Right Tool for Your Needs

Selecting between a dynamometer and a tachometer depends on your specific measurement goals; a dynamometer measures torque and power output, making it ideal for engine performance testing, while a tachometer focuses on rotational speed. For applications requiring detailed engine load and power analysis, a dynamometer provides comprehensive data, whereas a tachometer is more suitable for monitoring RPM in real-time. Understanding your project's requirements ensures you choose the tool that delivers the most relevant and precise information for your needs.

Future Trends and Technological Advancements

Dynamometers and tachometers are evolving with advancements in digital sensors, wireless connectivity, and real-time data analytics, enhancing accuracy and usability in performance testing. Emerging technologies like AI integration and IoT enable predictive maintenance and remote monitoring, streamlining engine diagnostics and efficiency optimization. Your ability to leverage these innovations will improve precision in measuring rotational speed and torque for various automotive and industrial applications.

Dynamometer vs tachometer Infographic

libmatt.com

libmatt.com