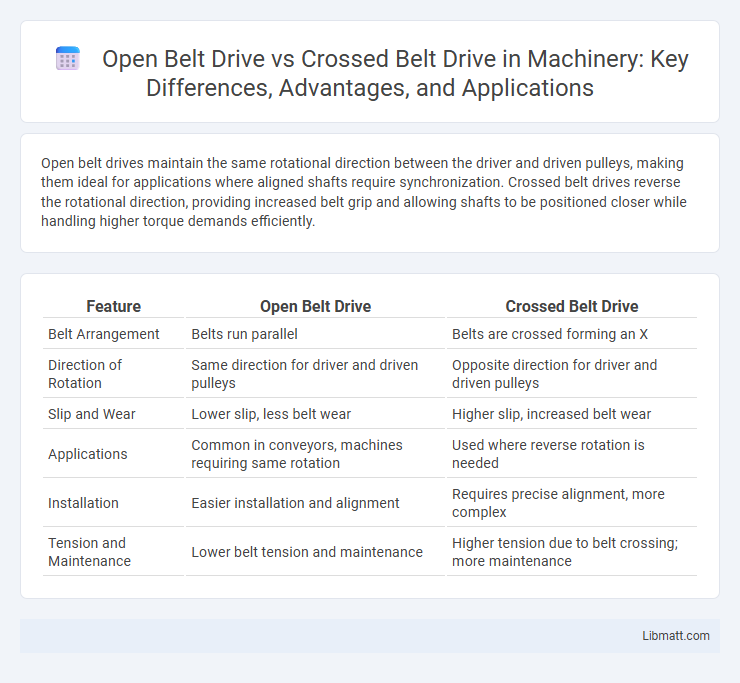

Open belt drives maintain the same rotational direction between the driver and driven pulleys, making them ideal for applications where aligned shafts require synchronization. Crossed belt drives reverse the rotational direction, providing increased belt grip and allowing shafts to be positioned closer while handling higher torque demands efficiently.

Table of Comparison

| Feature | Open Belt Drive | Crossed Belt Drive |

|---|---|---|

| Belt Arrangement | Belts run parallel | Belts are crossed forming an X |

| Direction of Rotation | Same direction for driver and driven pulleys | Opposite direction for driver and driven pulleys |

| Slip and Wear | Lower slip, less belt wear | Higher slip, increased belt wear |

| Applications | Common in conveyors, machines requiring same rotation | Used where reverse rotation is needed |

| Installation | Easier installation and alignment | Requires precise alignment, more complex |

| Tension and Maintenance | Lower belt tension and maintenance | Higher tension due to belt crossing; more maintenance |

Introduction to Belt Drive Systems

Belt drive systems transmit mechanical power between shafts using continuous belts, with open and crossed belt drives as common configurations. Open belt drives maintain parallel shafts and provide smooth power transmission with minimal belt wear, ideal for applications requiring consistent speed. Crossed belt drives, where belts cross in an "X" shape, enable reverse rotation between shafts, offering flexibility for specific machinery setups but may cause increased belt tension and wear.

Overview of Open Belt Drive

Open belt drive consists of two pulleys rotating in the same direction connected by a belt running parallel without twisting. This system is widely used for transmitting power between shafts that are parallel and requires minimal maintenance due to its simple design. You can expect smooth and efficient operation in applications like conveyor systems and industrial machinery with an open belt drive.

Overview of Crossed Belt Drive

Crossed belt drive features a belt twisted in a figure-eight shape, enabling the driver and driven pulleys to rotate in opposite directions. This configuration provides increased friction and grip, reducing the risk of belt slippage compared to an open belt drive. Your machinery benefits from enhanced torque transmission and alignment flexibility when utilizing crossed belt drives.

Key Differences Between Open and Crossed Belt Drives

Open belt drives transmit motion between two parallel shafts, ensuring the same direction of rotation, while crossed belt drives connect shafts that rotate in opposite directions by crossing the belt. Open belts typically offer easier maintenance and reduced belt wear due to less tension and friction, whereas crossed belts provide enhanced grip and higher torque transmission at the cost of increased belt stress. Your choice between these drive types depends on the required direction of shaft rotation and operational efficiency in power transmission systems.

Power Transmission Efficiency Comparison

Open belt drives generally provide higher power transmission efficiency due to less belt tension and reduced bending stress on the belt. Crossed belt drives, while allowing for reverse rotation, often experience increased friction and heat generation from belt twisting, leading to slightly lower efficiency. Efficiency in open belt drives typically ranges between 90-95%, whereas crossed belt drives usually fall around 85-90%.

Direction of Rotation in Both Belt Drives

Open belt drives maintain the same direction of rotation between the driver and driven pulleys, ensuring synchronized movement in machinery. Crossed belt drives reverse the direction of rotation, causing the driven pulley to rotate opposite to the driver pulley. Your choice between these two depends on the required rotational direction for specific mechanical applications.

Applications of Open Belt Drive

Open belt drives are commonly used in applications requiring parallel shaft alignment, such as conveyor systems, agricultural machinery, and automotive fans, where smooth, efficient power transmission is essential. Their simpler design allows for easy installation and maintenance, making them ideal for moderate-speed operations in industries like manufacturing and packaging. You benefit from open belt drives when your setup demands low noise and consistent tension without complex shaft arrangements.

Applications of Crossed Belt Drive

Crossed belt drives are commonly used in applications requiring the reversal of rotational direction between shafts, such as in woodworking machinery and conveyor systems. Their capability to transmit power efficiently while maintaining tension makes them suitable for small to medium power transmission needs in agricultural equipment and machine tools. The crossed belt design also helps maintain consistent speed and reduces slippage in devices where precise motion control is critical.

Advantages and Disadvantages of Each System

Open belt drives offer easy installation and maintenance with minimal shaft alignment issues, making them ideal for transmitting power between parallel shafts; however, they tend to slip under heavy loads and are less efficient at high speeds. Crossed belt drives provide better grip and increased torque transmission by creating a greater wrap angle, but they generate more heat, wear out faster, and require precise alignment to avoid excessive belt tension. Your choice depends on whether ease of maintenance or higher torque capacity is the priority in your mechanical system.

Choosing the Right Belt Drive for Your Needs

Open belt drives offer efficient power transmission with minimal belt wear, suitable for parallel shaft applications requiring less tension and simpler maintenance. Crossed belt drives provide increased friction and power transmission by twisting the belt to reverse shaft rotation, ideal for compact setups needing opposite rotational directions. Selecting the right belt drive depends on shaft alignment, desired rotation direction, space constraints, and required torque capacity.

Open belt drive vs crossed belt drive Infographic

libmatt.com

libmatt.com