Wet blasting uses a mixture of water and abrasive media to clean or finish surfaces, reducing dust and heat for a smoother, more precise result. Dry blasting, on the other hand, employs dry abrasive particles for faster material removal but may create more dust and require greater airflow management to maintain a clean workspace.

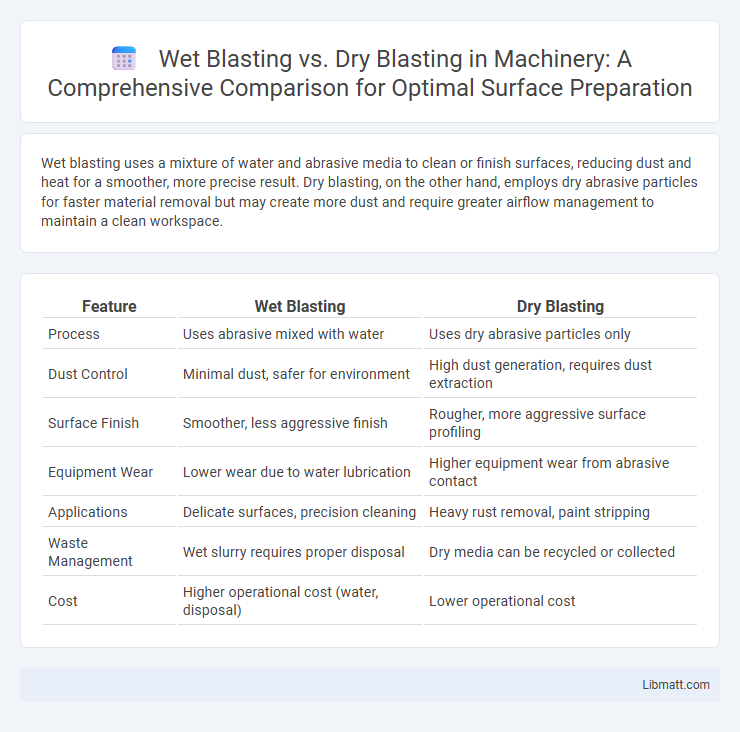

Table of Comparison

| Feature | Wet Blasting | Dry Blasting |

|---|---|---|

| Process | Uses abrasive mixed with water | Uses dry abrasive particles only |

| Dust Control | Minimal dust, safer for environment | High dust generation, requires dust extraction |

| Surface Finish | Smoother, less aggressive finish | Rougher, more aggressive surface profiling |

| Equipment Wear | Lower wear due to water lubrication | Higher equipment wear from abrasive contact |

| Applications | Delicate surfaces, precision cleaning | Heavy rust removal, paint stripping |

| Waste Management | Wet slurry requires proper disposal | Dry media can be recycled or collected |

| Cost | Higher operational cost (water, disposal) | Lower operational cost |

Introduction to Wet Blasting and Dry Blasting

Wet blasting uses a mixture of water and abrasive media to clean or finish surfaces, reducing dust and heat generation for delicate or heat-sensitive materials. Dry blasting employs dry abrasive materials propelled by compressed air, ideal for heavy-duty cleaning, rust removal, and surface preparation on tougher substrates. Both methods offer distinct advantages depending on the application, material type, and desired finish quality.

Key Differences Between Wet and Dry Blasting

Wet blasting uses a combination of water and abrasive media, reducing dust and heat generation, making it ideal for delicate surfaces and minimizing environmental impact. Dry blasting relies solely on abrasive media propelled by compressed air, offering faster material removal but producing more dust and heat, which can damage sensitive materials. The key differences lie in moisture content, dust control, surface finish quality, and suitability for various substrate types.

Equipment Used in Wet vs Dry Blasting

Wet blasting utilizes a combination of water and abrasive media, often requiring specialized equipment such as slurry pumps, water recovery systems, and sealed blasting cabinets to handle the wet mixture. Dry blasting equipment typically includes compressed air systems, blasting pots, and dry abrasive feeders designed to propel dry media at high velocity for surface cleaning or preparation. Your choice between wet and dry blasting equipment depends on the project requirements, such as dust control, surface sensitivity, and environmental considerations.

Surface Finish Quality Comparison

Wet blasting produces a smoother and more uniform surface finish compared to dry blasting, as the water helps reduce dust and removes debris more effectively. Dry blasting can cause surface etching and uneven textures due to the direct impact of abrasive media without moisture. Choosing wet blasting enhances your surface finish quality by minimizing micro-cracks and promoting a cleaner, more polished appearance.

Dust and Contaminant Control

Wet blasting significantly reduces dust and airborne contaminants by using a mixture of water and abrasive media, which captures particles and prevents them from becoming airborne. Dry blasting generates more dust, posing greater risks for respiratory issues and requiring more extensive containment measures. Your choice between wet and dry blasting should consider the level of dust control needed for a safer and cleaner working environment.

Health and Safety Considerations

Wet blasting significantly reduces dust generation compared to dry blasting, lowering the risk of respiratory issues and airborne contaminants for workers. The presence of water in wet blasting minimizes fire hazards and decreases abrasive particle rebound, enhancing workplace safety. In contrast, dry blasting produces more dust and airborne particles, requiring stringent protective gear and ventilation systems to mitigate health risks.

Environmental Impact Assessment

Wet blasting significantly reduces dust emissions compared to dry blasting, minimizing air pollution and promoting better air quality. It uses water to suppress airborne particulates, which decreases the release of harmful contaminants into the environment. You can achieve a more environmentally responsible cleaning process by choosing wet blasting, especially in areas with strict environmental regulations.

Application Areas for Wet and Dry Blasting

Wet blasting excels in applications requiring delicate surface cleaning, rust removal, and paint stripping on metal, glass, and plastic, making it ideal for automotive restoration and aerospace maintenance. Dry blasting is preferred for tougher industrial tasks like abrasive cleaning of concrete, metal fabrication, and heavy-duty paint removal where extensive dust control is less critical. You can optimize surface preparation by selecting wet blasting for precision and dust-sensitive environments, while dry blasting suits high-impact, large-scale operations.

Cost and Operational Efficiency

Wet blasting typically incurs higher initial costs due to water and equipment maintenance but offers greater operational efficiency by reducing dust and abrasive consumption, leading to longer media life. Dry blasting generally has lower upfront expenses but may increase labor and cleanup costs, impacting overall productivity. Evaluating your specific project needs will help determine whether wet or dry blasting provides the most cost-effective and efficient solution.

Choosing the Right Blasting Method

Selecting the right blasting method hinges on the surface material and project requirements; wet blasting uses a mixture of water and abrasive media to reduce dust and minimize substrate damage, ideal for delicate surfaces or intricate parts. Dry blasting employs only abrasive media, offering faster cleaning and paint removal, suitable for heavy-duty applications and rough surfaces. Consider factors like environmental impact, surface sensitivity, and desired finish quality to determine whether wet blasting's moisture control or dry blasting's efficiency best meets your needs.

Wet blasting vs dry blasting Infographic

libmatt.com

libmatt.com