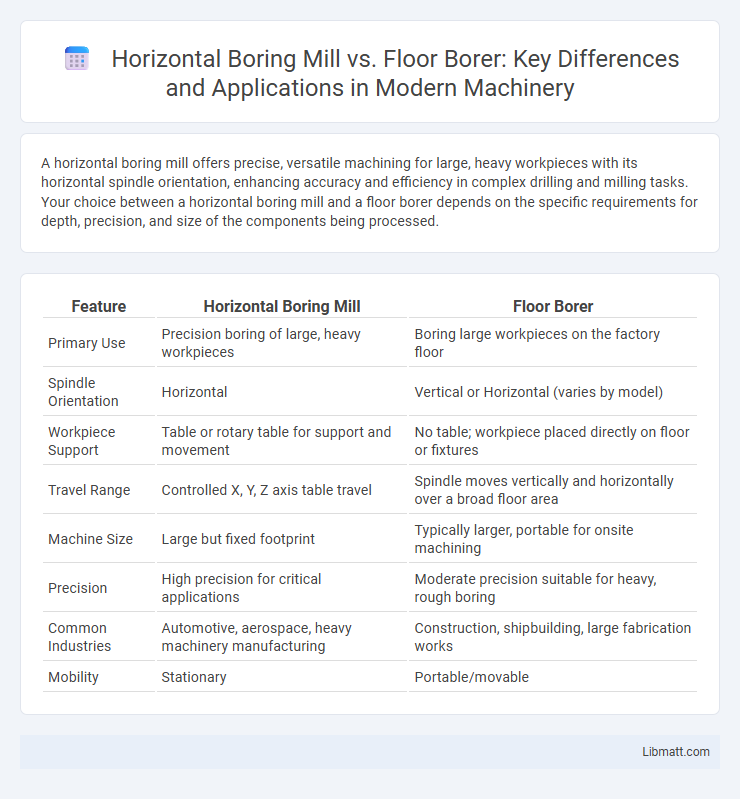

A horizontal boring mill offers precise, versatile machining for large, heavy workpieces with its horizontal spindle orientation, enhancing accuracy and efficiency in complex drilling and milling tasks. Your choice between a horizontal boring mill and a floor borer depends on the specific requirements for depth, precision, and size of the components being processed.

Table of Comparison

| Feature | Horizontal Boring Mill | Floor Borer |

|---|---|---|

| Primary Use | Precision boring of large, heavy workpieces | Boring large workpieces on the factory floor |

| Spindle Orientation | Horizontal | Vertical or Horizontal (varies by model) |

| Workpiece Support | Table or rotary table for support and movement | No table; workpiece placed directly on floor or fixtures |

| Travel Range | Controlled X, Y, Z axis table travel | Spindle moves vertically and horizontally over a broad floor area |

| Machine Size | Large but fixed footprint | Typically larger, portable for onsite machining |

| Precision | High precision for critical applications | Moderate precision suitable for heavy, rough boring |

| Common Industries | Automotive, aerospace, heavy machinery manufacturing | Construction, shipbuilding, large fabrication works |

| Mobility | Stationary | Portable/movable |

Introduction to Horizontal Boring Mills and Floor Borers

Horizontal boring mills excel in precision machining of large, heavy workpieces, utilizing a horizontally oriented spindle to perform drilling, boring, and milling operations with exceptional accuracy. Floor borers, characterized by their robust design and vertically oriented spindle mounted on a fixed base, are ideal for deep hole drilling and enlarging existing holes in large components. Your choice between these machines depends on the specific machining requirements, workpiece size, and desired tolerances for industrial manufacturing or repair tasks.

Key Differences Between Horizontal Boring Mills and Floor Borers

Horizontal boring mills offer greater versatility with multi-axis machining capabilities, allowing precise boring, milling, and drilling on large and heavy workpieces. Floor borers specialize in vertical boring and are ideal for deep, large-diameter holes, often used in heavy industries like power generation and shipbuilding. Your choice depends on required machining complexity, workpiece size, and operational flexibility needed for the specific application.

Design and Structural Features

Horizontal boring mills feature a robust, rigid structure with a spindle oriented horizontally, allowing precision machining of large workpieces through multi-axis movement and integrated rotary tables. Floor borers have a vertical spindle mounted on a heavy-duty column fixed directly to the floor, providing stability for deep hole boring and heavy-duty operations on large castings or machine components. The design of horizontal boring mills emphasizes versatility and complex contouring, while floor borers prioritize rigidity and support for heavy, static workpieces.

Operational Capabilities and Applications

Horizontal boring mills boast superior operational capabilities with high precision in large-scale machining tasks, making them ideal for heavy industrial applications such as engine block manufacturing and large gearbox fabrication. Floor borers excel in handling massive, bulky workpieces due to their robust structure and versatile spindle movement, commonly used in shipbuilding and construction equipment production. Both machines offer specialized solutions, with horizontal boring mills favored for intricate component machining and floor borers suited for machining structural parts with challenging dimensions.

Precision and Performance Comparison

Horizontal boring mills deliver exceptional precision with advanced rigidity and spindle accuracy, making them ideal for machining large, complex parts requiring tight tolerances. Floor borers offer robust performance for heavy-duty, large-scale drilling and boring tasks but often sacrifice the finer accuracy achievable with horizontal boring mills. You can expect improved surface finish and consistent repeatability from horizontal boring mills, while floor borers excel in handling higher load capacities in construction and heavy manufacturing environments.

Size and Workpiece Capacity

Horizontal boring mills offer larger size options and can accommodate significantly heavier and larger workpieces, making them ideal for machining large engine blocks, heavy machinery components, and industrial parts. Floor borers typically have a smaller footprint and are suited for medium-sized workpieces that require precision but do not exceed the capacity of horizontal boring mills. Your choice should depend on the dimensions and weight of the workpiece to ensure optimal performance and machining accuracy.

Flexibility and Versatility in Machining

Horizontal boring mills offer greater flexibility and versatility in machining complex, large-scale parts due to their ability to handle multi-axis movements and accommodate various tooling options. Floor borers excel in heavy-duty, large-diameter hole drilling but typically lack the multi-functional capabilities and precision adjustments found in horizontal boring mills. Your choice depends on whether your machining projects demand intricate versatility or primarily focus on straightforward, heavy drilling tasks.

Cost Factors and Investment Considerations

Horizontal boring mills generally require a higher initial investment due to their advanced precision and versatility in machining large, complex parts, making them suitable for high-volume or specialized manufacturing. Floor borers tend to have lower upfront costs and simpler operation, ideal for less intensive or smaller-scale projects with limited budgets. Your decision should consider long-term productivity gains and maintenance expenses alongside initial purchase price to optimize cost-effectiveness.

Maintenance and Longevity

Horizontal boring mills typically require regular lubrication and calibration to maintain precision, resulting in longer operational lifespan when properly serviced. Floor borers need frequent inspection of the spindle and motor components to prevent wear and ensure consistent performance, influencing their durability. Both machines benefit from routine preventative maintenance to maximize longevity and minimize downtime.

Choosing the Right Machine for Your Workshop

Selecting between a horizontal boring mill and a floor borer depends on the specific requirements of your workshop, including workpiece size, precision, and versatility. Horizontal boring mills excel in machining large, heavy components with high accuracy and can handle complex setups, while floor borers are ideal for deep drilling and boring tasks on heavy workpieces where vertical machining is preferred. Understanding your production needs and the type of operations you perform will guide you in choosing the machine that maximizes efficiency and precision in your workshop.

Horizontal boring mill vs floor borer Infographic

libmatt.com

libmatt.com