Electrical discharge machining (EDM) uses electrical sparks to erode material from a workpiece, making it ideal for hard metals and complex shapes. Electrochemical machining (ECM) removes material through controlled anodic dissolution, offering smooth finishes without thermal or mechanical stress on your parts.

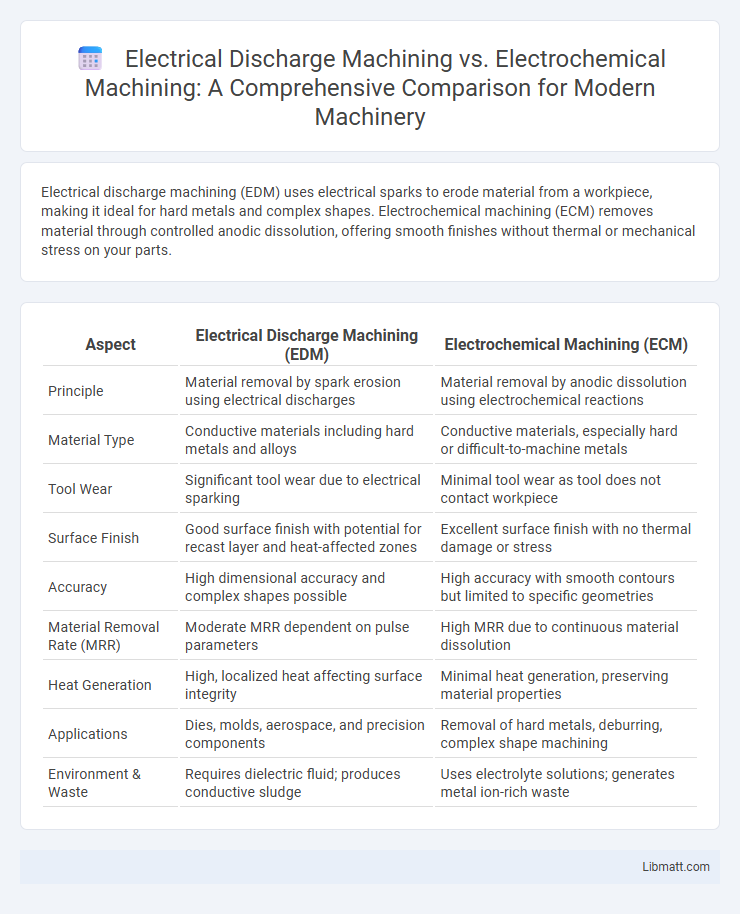

Table of Comparison

| Aspect | Electrical Discharge Machining (EDM) | Electrochemical Machining (ECM) |

|---|---|---|

| Principle | Material removal by spark erosion using electrical discharges | Material removal by anodic dissolution using electrochemical reactions |

| Material Type | Conductive materials including hard metals and alloys | Conductive materials, especially hard or difficult-to-machine metals |

| Tool Wear | Significant tool wear due to electrical sparking | Minimal tool wear as tool does not contact workpiece |

| Surface Finish | Good surface finish with potential for recast layer and heat-affected zones | Excellent surface finish with no thermal damage or stress |

| Accuracy | High dimensional accuracy and complex shapes possible | High accuracy with smooth contours but limited to specific geometries |

| Material Removal Rate (MRR) | Moderate MRR dependent on pulse parameters | High MRR due to continuous material dissolution |

| Heat Generation | High, localized heat affecting surface integrity | Minimal heat generation, preserving material properties |

| Applications | Dies, molds, aerospace, and precision components | Removal of hard metals, deburring, complex shape machining |

| Environment & Waste | Requires dielectric fluid; produces conductive sludge | Uses electrolyte solutions; generates metal ion-rich waste |

Introduction to Electrical Discharge Machining (EDM) and Electrochemical Machining (ECM)

Electrical Discharge Machining (EDM) utilizes controlled electrical sparks to erode material from conductive workpieces, enabling precise machining of complex shapes and hard metals. Electrochemical Machining (ECM) removes metal through anodic dissolution by passing an electric current between a shaped tool and the workpiece in an electrolyte solution, allowing for stress-free machining of difficult-to-cut materials. Both EDM and ECM are non-contact processes well-suited for high-precision manufacturing in aerospace, mold making, and medical device industries.

Basic Principles: How EDM and ECM Work

Electrical Discharge Machining (EDM) removes material by generating controlled electrical sparks between an electrode and the workpiece, causing localized melting and vaporization. Electrochemical Machining (ECM) utilizes anodic dissolution through an electrolytic cell where the workpiece acts as the anode, and metal ions are removed via electrochemical reactions without heat. Both processes allow precise material removal but differ fundamentally in energy source and material interaction mechanisms.

Key Differences Between EDM and ECM

Electrical Discharge Machining (EDM) utilizes controlled electrical sparks to erode material, making it ideal for hard metals and intricate shapes, whereas Electrochemical Machining (ECM) employs anodic dissolution in an electrolytic solution to remove material without mechanical stress. EDM is precise for complex cavities but may cause thermal damage, while ECM offers smooth surface finishes and faster machining for harder materials without heat-affected zones. Your choice depends on the material properties and required surface quality, with EDM excelling in fine detail and ECM in maintaining material integrity.

Materials Suitable for EDM vs ECM

Electrical discharge machining (EDM) is highly effective for machining hard, electrically conductive materials such as hardened steels, titanium alloys, and tungsten carbide, which are difficult to machine using conventional methods. Electrochemical machining (ECM) excels in removing materials like stainless steel, tool steels, and superalloys by controlled anodic dissolution, especially suited for corrosion-resistant and tough metals. While EDM relies on electrical sparks to erode conductive materials regardless of hardness, ECM uses electrochemical reactions that avoid thermal damage, making it ideal for complex shapes in sensitive alloys.

Surface Finish and Accuracy Comparison

Electrical Discharge Machining (EDM) typically produces finer surface finishes with roughness values ranging from Ra 0.1 to 0.8 micrometers, making it suitable for high-precision applications requiring tight tolerances and sharp details. Electrochemical Machining (ECM) offers excellent accuracy with minimal residual stress and smooth surface finishes, often achieving Ra values around 0.4 to 1.0 micrometers, ideal for complex geometries and hard-to-machine materials. EDM's ability to create intricate shapes with precise dimensional control contrasts with ECM's advantage in superior surface integrity and burr-free edges due to its non-thermal material removal process.

Tool Wear and Electrode Considerations

Electrical discharge machining (EDM) involves significant tool wear due to electrode erosion caused by spark discharges, necessitating the use of wear-resistant materials like graphite or copper alloys to maintain precision. In contrast, electrochemical machining (ECM) features minimal tool wear because material removal occurs through anodic dissolution without direct contact, allowing the electrode to retain its shape and dimensions consistently. Electrode considerations in EDM prioritize thermal and electrical conductivity, whereas ECM electrodes demand corrosion resistance and stability in the electrolyte environment to ensure process efficiency.

Applications of EDM and ECM in Industry

Electrical discharge machining (EDM) excels in producing intricate shapes and fine details in hard metals, making it ideal for aerospace, automotive, and mold-making industries. Electrochemical machining (ECM) is preferred for removing large amounts of material without thermal or mechanical stress, commonly used in turbine blade manufacturing and aerospace components. Your choice between EDM and ECM depends on the required precision, material type, and production speed in industrial applications.

Process Limitations and Challenges

Electrical discharge machining (EDM) faces limitations such as difficulty machining non-conductive materials and a slower material removal rate compared to other methods. Electrochemical machining (ECM) struggles with challenges including managing electrolyte disposal, potential environmental hazards, and the need for precise control to avoid overcutting. Your choice between EDM and ECM should consider these constraints alongside material compatibility and desired surface finish.

Environmental Impact and Safety Concerns

Electrical discharge machining (EDM) produces hazardous waste containing dielectric fluids and fine metal particles, requiring careful disposal and posing fire risks due to flammable oils. Electrochemical machining (ECM) generates less hazardous waste, using aqueous electrolytes that, while corrosive, are easier to treat and dispose of, but it involves handling toxic chemicals and risk of hydrogen gas evolution. Both methods demand stringent safety protocols to protect operators from chemical exposure, electrical hazards, and environmental contamination.

Choosing Between EDM and ECM: Factors to Consider

Choosing between Electrical Discharge Machining (EDM) and Electrochemical Machining (ECM) depends on material conductivity, precision requirements, and surface finish. EDM excels in machining hard, conductive materials with intricate shapes and tight tolerances, while ECM is ideal for removing metal without thermal stress, preserving material integrity in delicate parts. Your selection should consider workpiece hardness, desired surface quality, and production speed to optimize machining efficiency.

Electrical discharge machining vs electrochemical machining Infographic

libmatt.com

libmatt.com