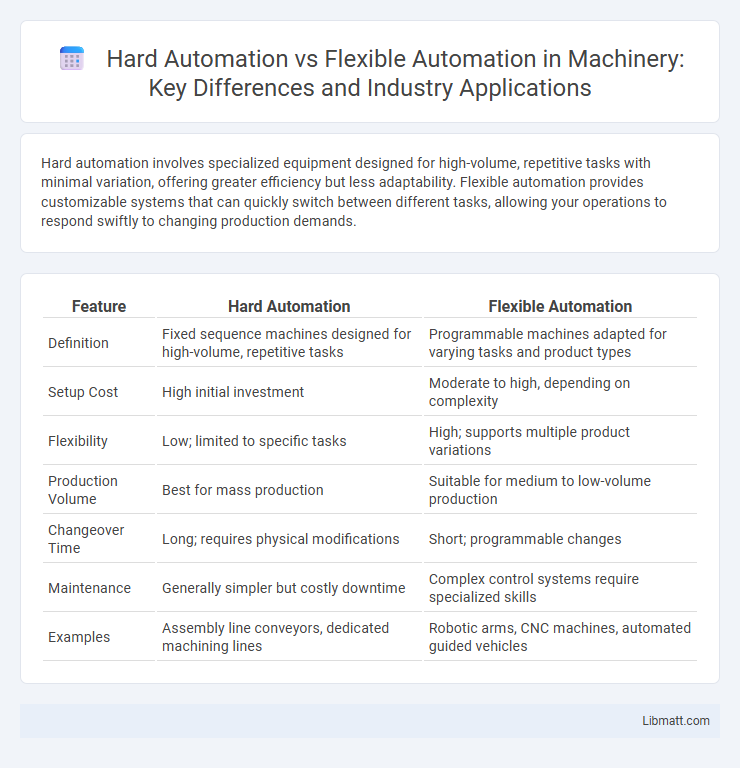

Hard automation involves specialized equipment designed for high-volume, repetitive tasks with minimal variation, offering greater efficiency but less adaptability. Flexible automation provides customizable systems that can quickly switch between different tasks, allowing your operations to respond swiftly to changing production demands.

Table of Comparison

| Feature | Hard Automation | Flexible Automation |

|---|---|---|

| Definition | Fixed sequence machines designed for high-volume, repetitive tasks | Programmable machines adapted for varying tasks and product types |

| Setup Cost | High initial investment | Moderate to high, depending on complexity |

| Flexibility | Low; limited to specific tasks | High; supports multiple product variations |

| Production Volume | Best for mass production | Suitable for medium to low-volume production |

| Changeover Time | Long; requires physical modifications | Short; programmable changes |

| Maintenance | Generally simpler but costly downtime | Complex control systems require specialized skills |

| Examples | Assembly line conveyors, dedicated machining lines | Robotic arms, CNC machines, automated guided vehicles |

Understanding Hard Automation: Definition and Key Features

Hard automation involves using fixed equipment designed for high-volume production with minimal variation, characterized by specialized machinery and rigid control systems tailored to specific tasks. Its key features include high production efficiency, low unit cost, and limited adaptability to product changes, making it ideal for repetitive manufacturing processes. You benefit from hard automation when consistency and speed are critical, but flexibility for design modifications is less important.

What Is Flexible Automation? Core Concepts Explained

Flexible automation refers to automated systems designed to handle varying tasks with minimal reprogramming, enhancing manufacturing adaptability and efficiency. Unlike hard automation, which is fixed and tailored for specific repetitive tasks, flexible automation utilizes programmable machines and robotics to switch between products or processes quickly. Your production line benefits from reduced downtime and increased responsiveness to changing market demands through this versatile automation approach.

Comparing System Design: Hard vs Flexible Automation

Hard automation systems feature fixed sequence operations tailored for high-volume production with minimal variation, emphasizing dedicated machinery and long setup times. Flexible automation incorporates programmable equipment and robotics, allowing quick adaptation to diverse tasks and product changes, which enhances efficiency in lower-volume and customized manufacturing. Understanding these design differences enables you to choose the ideal system based on production flexibility and scalability requirements.

Cost Implications: Upfront Investment and Long-Term Savings

Hard automation requires a significant upfront investment due to custom-designed equipment tailored for specific tasks, resulting in high initial costs but lower variable expenses over time. Flexible automation involves moderate initial spending with reprogrammable systems that adapt to different products, offering long-term savings through reduced changeover costs and enhanced versatility. Your choice between hard and flexible automation impacts overall cost efficiency based on production volume and product variety.

Production Volume and Product Variety: Suitability Analysis

Hard automation excels in high production volume scenarios with low product variety, offering fast, repetitive, and cost-efficient manufacturing for standardized products. Flexible automation suits low to medium production volumes requiring high product variety, enabling easy reprogramming and adaptability to changing product designs. Your choice depends on balancing production scale with the need for customization and responsiveness in manufacturing processes.

Speed and Efficiency: Performance Metrics

Hard automation excels in speed and efficiency for high-volume, repetitive tasks, delivering consistent cycle times and minimizing variability. Flexible automation offers moderate speed but significantly improves adaptability, reducing changeover times and enhancing overall equipment effectiveness (OEE). Key performance metrics include throughput rate, takt time, and downtime percentage, with hard automation optimized for maximum throughput and flexible systems emphasizing operational flexibility and reduced setup time.

Adaptability to Change: Flexibility in Manufacturing Processes

Hard automation offers low adaptability to change due to its fixed programming and dedicated machinery designed for high-volume, repetitive tasks. Flexible automation provides high adaptability through programmable controllers and modular equipment, enabling rapid adjustments to varying product designs and batch sizes. This flexibility reduces downtime and increases efficiency in manufacturing processes that require frequent changeovers.

Maintenance Requirements for Each Automation Type

Hard automation demands intensive maintenance due to its fixed, specialized machinery designed for high-volume production, requiring frequent calibration and parts replacement to avoid downtime. Flexible automation systems have lower maintenance requirements because of their adaptable software-driven controls and modular components, enabling easier updates and minimal physical wear. Regular software updates and preventive hardware checks are essential to sustain optimal performance in flexible automation environments.

Industry Applications: Where Hard and Flexible Automation Shine

Hard automation excels in mass production industries such as automotive manufacturing and consumer electronics, where repetitive, high-volume tasks demand consistent precision and efficiency. Flexible automation suits industries requiring customization and variability, like aerospace and pharmaceuticals, enabling quick adaptation to product changes without major retooling. Your choice between hard and flexible automation depends on production volume, variability, and the need for rapid changeover in industrial applications.

Future Trends: Evolving Roles of Automation Technologies

Hard automation, characterized by fixed sequences and specialized machinery, is gradually being supplemented by flexible automation systems that leverage advanced robotics and AI to adapt to changing production demands. Future trends indicate a significant shift toward hybrid automation models that integrate real-time data analytics and machine learning, enabling rapid reconfiguration and enhanced efficiency in manufacturing processes. These evolving roles of automation technologies will drive increased customization, reduced downtime, and greater scalability across diverse industrial sectors.

Hard automation vs flexible automation Infographic

libmatt.com

libmatt.com