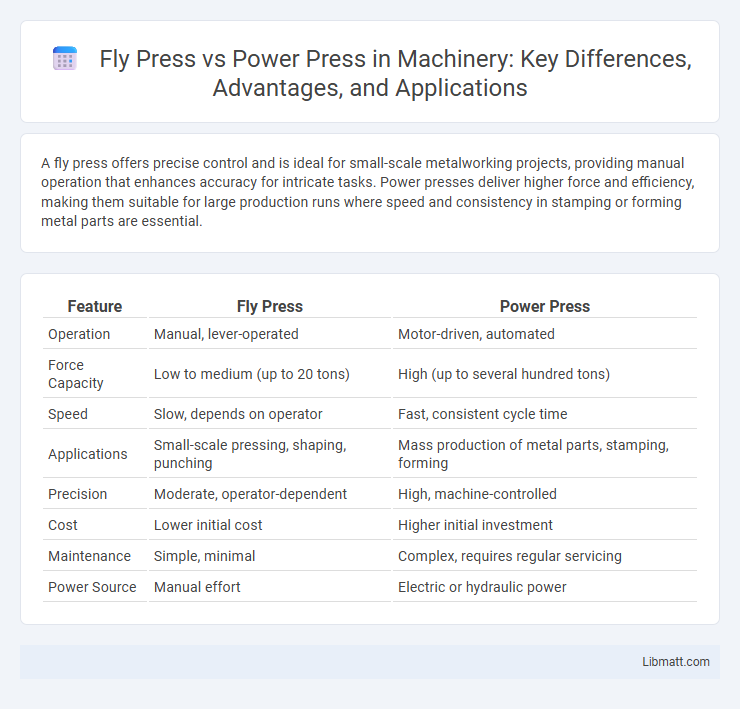

A fly press offers precise control and is ideal for small-scale metalworking projects, providing manual operation that enhances accuracy for intricate tasks. Power presses deliver higher force and efficiency, making them suitable for large production runs where speed and consistency in stamping or forming metal parts are essential.

Table of Comparison

| Feature | Fly Press | Power Press |

|---|---|---|

| Operation | Manual, lever-operated | Motor-driven, automated |

| Force Capacity | Low to medium (up to 20 tons) | High (up to several hundred tons) |

| Speed | Slow, depends on operator | Fast, consistent cycle time |

| Applications | Small-scale pressing, shaping, punching | Mass production of metal parts, stamping, forming |

| Precision | Moderate, operator-dependent | High, machine-controlled |

| Cost | Lower initial cost | Higher initial investment |

| Maintenance | Simple, minimal | Complex, requires regular servicing |

| Power Source | Manual effort | Electric or hydraulic power |

Introduction to Fly Press and Power Press

Fly press is a manual forging tool used to shape metal through gradual application of force, ideal for small-scale or precision work with its lever and flywheel mechanism. Power press operates using motor-driven mechanical or hydraulic systems, delivering high-speed, repetitive force suitable for large-scale manufacturing and stamping operations. Both presses serve distinct industrial applications, with fly press favored for intricate tasks and power press optimized for high-volume production efficiency.

Working Principle of Fly Press

The working principle of a fly press involves manual operation using a large flywheel connected to a ram, which is driven by a hand lever to exert force on the material being pressed. The rotational motion of the flywheel is converted into linear motion, allowing precise control and slow speed for tasks requiring accuracy and moderate force. Unlike a power press that uses an electric motor for rapid, high-force operations, the fly press relies entirely on mechanical leverage and operator input.

Working Mechanism of Power Press

Power press operates through an electric motor that drives a crankshaft connected to a ram, enabling precise and repetitive stamping or cutting actions with high force. The motor's rotational energy is converted into linear motion via the crank mechanism, allowing for adjustable stroke lengths and uniform pressure application. This automated system enhances production efficiency and accuracy compared to the manual fly press.

Key Components Comparison

Fly press features a simple lever, ram, bolster plate, and anvil, relying on manual force for operation, making it ideal for light-duty tasks like forming, bending, and punching. Power press incorporates a motor-driven flywheel, crankshaft, clutch, ram, and bed, enabling high-speed, heavy-duty stamping and shaping with precision and consistent power. The key components of power presses ensure greater automation and productivity compared to the mechanically simpler fly press.

Applications of Fly Press

Fly presses are primarily used in light-duty forging, blanking, and forming operations where precise control and low to medium tonnage are required. They excel in applications such as jewel manufacturing, small metal component fabrication, and prototyping due to their simplicity and ease of customization. Ideal for small workshops, fly presses offer manual operation versatility for specialized tasks not suited to high-volume production like those handled by power presses.

Applications of Power Press

Power presses are essential in high-volume manufacturing for processes such as stamping, punching, bending, and forming metal sheets with consistent precision. Unlike fly presses, power presses provide greater force and automation, making them suitable for automotive, aerospace, and appliance industries where speed and repeatability are critical. Your production efficiency significantly increases when utilizing power presses for complex and repetitive tasks that demand accuracy and high output.

Advantages of Fly Press

Fly presses offer greater control and precision for delicate metalworking tasks, making them ideal for small to medium-sized production runs. Their simple mechanical design reduces maintenance costs and enhances reliability, ensuring consistent performance over time. The ability to manually adjust pressure and speed helps achieve superior accuracy in intricate stamping, bending, and forming processes.

Advantages of Power Press

Power presses offer higher operational speed and consistent force application, significantly increasing productivity in metal forming processes. Their automation capability reduces manual labor, enhancing safety and precision in tasks such as punching, bending, and stamping. The adjustable stroke length and force settings provide versatile handling of various materials and thicknesses, optimizing manufacturing efficiency.

Limitations of Each Press Type

Fly presses are limited by their manual operation, restricting the maximum force and speed achievable, which makes them unsuitable for high-volume or heavy-duty production. Power presses, while capable of delivering higher force and faster cycle times, face limitations due to higher energy consumption, complexity, and increased maintenance requirements. Both types require careful consideration of application specifics to avoid issues like tool wear, operator fatigue, or production inefficiencies.

Choosing the Right Press for Your Needs

Choosing between a fly press and a power press depends on the scale and precision of your project. Fly presses excel in low-volume, manual operations requiring fine control, while power presses offer high-speed automation ideal for mass production. Understanding your production volume, force requirements, and budget ensures you select the press that maximizes efficiency and meets your manufacturing goals.

Fly press vs power press Infographic

libmatt.com

libmatt.com