A pick and place robot excels in high-speed, repetitive tasks with simple linear movements, making it ideal for basic assembly and packaging applications. Your choice depends on the complexity and precision required, as SCARA robots offer greater flexibility and accuracy for intricate tasks involving horizontal movement and precise component placement.

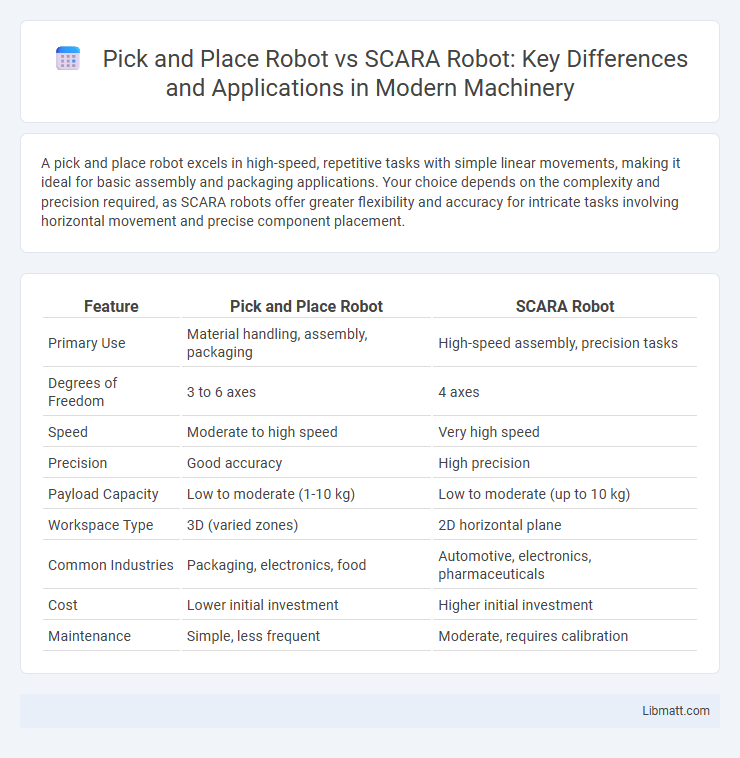

Table of Comparison

| Feature | Pick and Place Robot | SCARA Robot |

|---|---|---|

| Primary Use | Material handling, assembly, packaging | High-speed assembly, precision tasks |

| Degrees of Freedom | 3 to 6 axes | 4 axes |

| Speed | Moderate to high speed | Very high speed |

| Precision | Good accuracy | High precision |

| Payload Capacity | Low to moderate (1-10 kg) | Low to moderate (up to 10 kg) |

| Workspace Type | 3D (varied zones) | 2D horizontal plane |

| Common Industries | Packaging, electronics, food | Automotive, electronics, pharmaceuticals |

| Cost | Lower initial investment | Higher initial investment |

| Maintenance | Simple, less frequent | Moderate, requires calibration |

Introduction to Industrial Robotics

Pick and place robots excel in repetitive tasks requiring high-speed and precision for transferring objects between locations, commonly used in assembly and packaging industries. SCARA robots offer superior rigidity and accuracy in horizontal movement, making them ideal for tasks like assembly, dispensing, and pick and place applications requiring consistent vertical motion. Both types of industrial robots enhance automation efficiency, but SCARA robots engage better in applications demanding precise lateral movement and complex manipulations.

Overview of Pick and Place Robots

Pick and place robots are designed to automate the process of picking up objects from one location and placing them in another with high speed and precision, commonly used in assembly lines and packaging industries. Unlike SCARA robots which specialize in lateral movement for precise assembly applications, pick and place robots prioritize vertical and horizontal motions to handle tasks like sorting and material handling. Your choice between these robots depends on the application requirements, where pick and place robots excel in fast, repetitive tasks involving object transfer.

SCARA Robots: Features and Functions

SCARA robots feature a rigid, four-axis design optimized for high-speed, precision pick-and-place tasks within a horizontal plane. Their unique articulated arm structure enables efficient lateral movements and vertical motions, making them ideal for assembly, packaging, and material handling applications. Enhanced repeatability and compact footprint distinguish SCARA robots from traditional Cartesian pick-and-place robots, offering superior speed and flexibility in manufacturing environments.

Key Differences Between Pick and Place and SCARA Robots

Pick and place robots are primarily designed for rapid, repetitive tasks involving the sorting and movement of objects, offering high speed and simplicity in programming. SCARA robots, on the other hand, provide greater precision and rigidity, enabling complex assembly operations with horizontal articulation and vertical motion for enhanced flexibility. The key differences lie in their structural design, with pick and place robots focusing on linear movements, whereas SCARA robots utilize a combination of rotary joints for superior accuracy and versatility in industrial applications.

Speed and Precision Comparison

Pick and place robots and SCARA robots differ significantly in speed and precision, with SCARA robots generally offering higher speed and greater precision due to their rigid parallel arm design ideal for fast, repetitive tasks. Pick and place robots excel in flexibility but typically have slightly lower precision and speed compared to SCARA robots, which can reach cycle times as low as 0.3 seconds with repeatability often within +-0.02 mm. This makes SCARA robots the preferred choice for applications requiring rapid, precise movements such as assembly and packaging in electronics manufacturing.

Application Areas: Pick and Place vs. SCARA

Pick and place robots excel in high-speed sorting and packaging tasks across manufacturing, logistics, and food processing industries due to their precision and repeatability. SCARA robots are primarily used in assembly, electronics, and small parts handling applications where vertical rigidity and lateral movement accuracy are critical. Both robot types enhance automation but serve distinct roles based on their kinematic design and workspace suitability.

Flexibility and Adaptability

Pick and place robots offer high flexibility by handling various object sizes and shapes with ease, making them ideal for dynamic production lines. SCARA robots provide precise, fast, and repeatable movements but are generally less adaptable to complex tasks due to their fixed arm design. Your choice depends on whether you prioritize versatile handling or consistent, high-speed pick and place operations.

Cost Efficiency and Maintenance

Pick and place robots generally offer higher cost efficiency due to their simpler design and versatility in handling various tasks, reducing initial investment and operational expenses. SCARA robots, while slightly more expensive upfront, provide lower maintenance costs because of their rigid mechanical structure and fewer moving parts, resulting in enhanced durability and less frequent repairs. Both robot types optimize productivity, but pick and place robots excel in reducing total cost of ownership through flexible deployment in cost-sensitive applications.

Integration with Automation Systems

Pick and place robots offer seamless integration with various automation systems through standardized communication protocols and flexible end-effectors, making them ideal for high-speed sorting and assembly tasks. SCARA robots excel in precise, repeatable horizontal movements, providing enhanced compatibility with conveyor and vision systems for intricate electronics or packaging operations. Your choice depends on the complexity and speed requirements of the automation workflow, where integration efficiency directly impacts overall productivity.

Choosing the Right Robot for Your Industry

Pick and place robots excel in high-speed, repetitive tasks requiring simple movements, making them ideal for electronics assembly and packaging industries. SCARA robots offer more flexibility with precise vertical and horizontal motion suitable for complex assembly, testing, and material handling in automotive and pharmaceutical sectors. Evaluating payload capacity, reach, speed, and application complexity is critical when choosing the right robot for industry-specific automation needs.

Pick and place robot vs SCARA robot Infographic

libmatt.com

libmatt.com