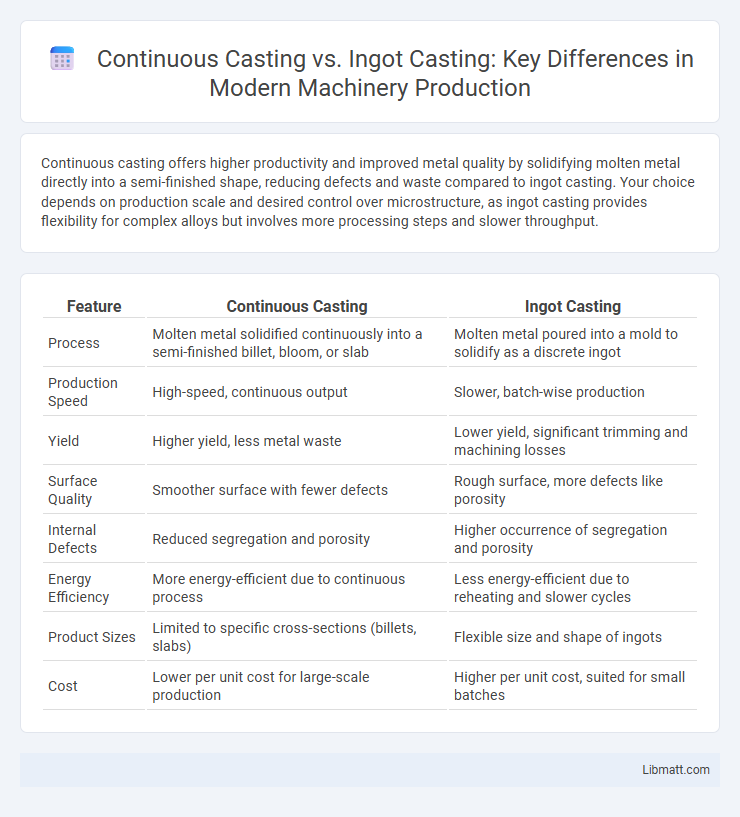

Continuous casting offers higher productivity and improved metal quality by solidifying molten metal directly into a semi-finished shape, reducing defects and waste compared to ingot casting. Your choice depends on production scale and desired control over microstructure, as ingot casting provides flexibility for complex alloys but involves more processing steps and slower throughput.

Table of Comparison

| Feature | Continuous Casting | Ingot Casting |

|---|---|---|

| Process | Molten metal solidified continuously into a semi-finished billet, bloom, or slab | Molten metal poured into a mold to solidify as a discrete ingot |

| Production Speed | High-speed, continuous output | Slower, batch-wise production |

| Yield | Higher yield, less metal waste | Lower yield, significant trimming and machining losses |

| Surface Quality | Smoother surface with fewer defects | Rough surface, more defects like porosity |

| Internal Defects | Reduced segregation and porosity | Higher occurrence of segregation and porosity |

| Energy Efficiency | More energy-efficient due to continuous process | Less energy-efficient due to reheating and slower cycles |

| Product Sizes | Limited to specific cross-sections (billets, slabs) | Flexible size and shape of ingots |

| Cost | Lower per unit cost for large-scale production | Higher per unit cost, suited for small batches |

Introduction to Steel Casting Methods

Continuous casting offers higher efficiency and improved steel quality compared to traditional ingot casting by solidifying molten steel directly into semifinished shapes like slabs or billets. Ingot casting involves pouring molten steel into molds, resulting in slower cooling rates and more internal defects such as segregation and porosity. Your choice between these methods impacts production speed, material properties, and cost-effectiveness in steel manufacturing.

Overview of Continuous Casting

Continuous casting produces metal slabs, billets, or blooms by solidifying molten metal directly into a semi-finished shape, enhancing efficiency and reducing waste compared to ingot casting. This process ensures uniform microstructure and superior surface quality due to controlled solidification rates and minimized segregation. Industrial applications favor continuous casting for steel, aluminum, and copper alloys, enabling higher productivity and improved mechanical properties over traditional ingot casting methods.

Overview of Ingot Casting

Ingot casting is a traditional metal casting process where molten metal is poured into large molds to solidify into blocks known as ingots, typically used for further rolling or forging. This method allows for slower cooling rates, which can result in coarser grain structures and less uniformity compared to continuous casting. Despite being less efficient, ingot casting remains prevalent in producing specialized alloys and large, custom-shaped billets.

Process Differences: Continuous vs Ingot Casting

Continuous casting involves the uninterrupted solidification of molten metal into a semi-finished billet, bloom, or slab, enhancing production efficiency and reducing defects. In contrast, ingot casting requires pouring molten metal into molds where it solidifies slowly, necessitating subsequent hot working to achieve desired shapes and properties. Your choice between these methods impacts manufacturing speed, material quality, and cost-effectiveness, with continuous casting offering streamlined operations and ingot casting providing flexibility for custom shapes.

Advantages of Continuous Casting

Continuous casting offers superior efficiency by producing semi-finished metal shapes directly from molten metal, reducing the need for extensive machining and minimizing waste. This process enhances metallurgical quality through better control of solidification, leading to uniform microstructure and reduced segregation. It also enables faster production rates and improved dimensional accuracy compared to traditional ingot casting methods.

Advantages of Ingot Casting

Ingot casting offers superior control over the solidification process, enabling the production of large, homogenous metal billets with minimal internal defects such as porosity or segregation. This method allows for flexible alloy compositions and simpler equipment requirements compared to continuous casting. Your choice of ingot casting ensures better customization for specialized metal grades and easier downstream processing like forging and rolling.

Quality Comparison: Surface and Internal Defects

Continuous casting offers superior quality by minimizing surface and internal defects such as cracks and porosity compared to ingot casting. The controlled solidification process in continuous casting reduces segregation and shrinkage cavities, resulting in a more uniform microstructure and enhanced mechanical properties. In contrast, ingot casting frequently experiences larger and more severe defects due to slower cooling rates and uneven solidification patterns.

Productivity and Cost Efficiency

Continuous casting significantly improves productivity by enabling the direct solidification of molten metal into semi-finished shapes, reducing cooling time and minimizing material waste. Ingot casting involves slower cooling cycles and additional processing steps, leading to higher labor and energy costs. The streamlined process of continuous casting lowers production costs and enhances yield, making it more cost-efficient for large-scale metal manufacturing.

Applications in the Steel Industry

Continuous casting revolutionizes the steel industry by enabling the efficient production of uniform billets, blooms, and slabs directly from molten steel, significantly reducing processing time and material waste. Ingot casting, while traditional and slower, remains valuable for producing customized or specialty steel shapes requiring specific mechanical properties. Your choice between these methods depends on production volume, quality requirements, and the final application of the steel products.

Future Trends in Metal Casting Technologies

Future trends in metal casting technologies emphasize continuous casting for its higher efficiency, superior metal quality, and reduced waste compared to ingot casting. Advancements in automation and real-time monitoring systems are enhancing precision and energy savings, making continuous casting increasingly vital in modern steel and aluminum production. Your choice between continuous and ingot casting should consider these trends to leverage improved sustainability and cost-effectiveness in manufacturing.

Continuous casting vs ingot casting Infographic

libmatt.com

libmatt.com