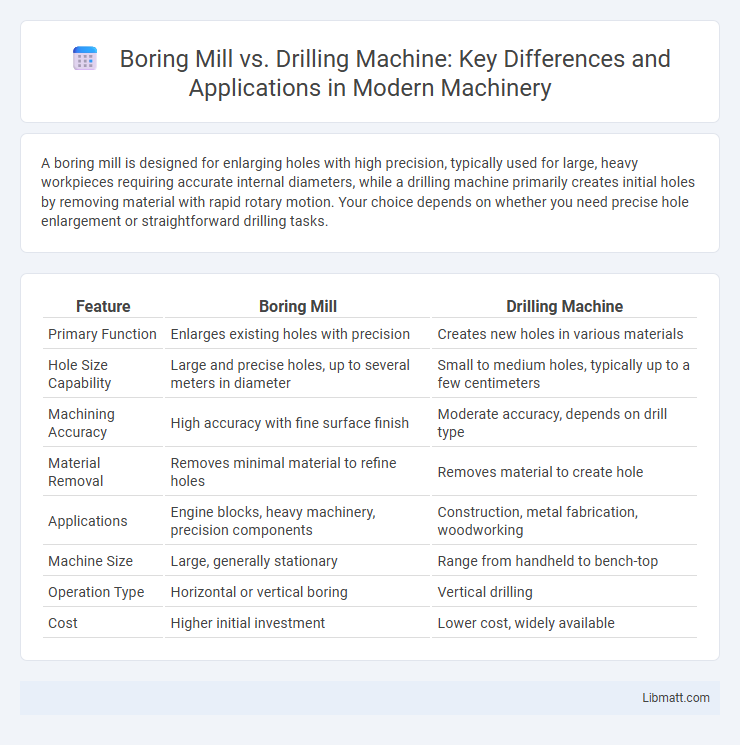

A boring mill is designed for enlarging holes with high precision, typically used for large, heavy workpieces requiring accurate internal diameters, while a drilling machine primarily creates initial holes by removing material with rapid rotary motion. Your choice depends on whether you need precise hole enlargement or straightforward drilling tasks.

Table of Comparison

| Feature | Boring Mill | Drilling Machine |

|---|---|---|

| Primary Function | Enlarges existing holes with precision | Creates new holes in various materials |

| Hole Size Capability | Large and precise holes, up to several meters in diameter | Small to medium holes, typically up to a few centimeters |

| Machining Accuracy | High accuracy with fine surface finish | Moderate accuracy, depends on drill type |

| Material Removal | Removes minimal material to refine holes | Removes material to create hole |

| Applications | Engine blocks, heavy machinery, precision components | Construction, metal fabrication, woodworking |

| Machine Size | Large, generally stationary | Range from handheld to bench-top |

| Operation Type | Horizontal or vertical boring | Vertical drilling |

| Cost | Higher initial investment | Lower cost, widely available |

Introduction to Boring Mills and Drilling Machines

Boring mills and drilling machines are essential machine tools used for precise hole-making and enlargement in metalworking and manufacturing industries. A boring mill specializes in enlarging existing holes with high accuracy and surface finish, while a drilling machine creates new holes by removing material from a workpiece. Understanding the distinct functions of your boring mill and drilling machine helps optimize machining processes for efficiency and quality.

Key Differences Between Boring Mills and Drilling Machines

Boring mills and drilling machines serve distinct purposes in machining; boring mills are designed for enlarging and finishing existing holes with precision, while drilling machines create new holes by cutting into the material. Boring mills offer greater accuracy and surface finish control, ideal for cylindrical workpieces, whereas drilling machines prioritize speed and versatility in producing holes of various diameters. Understanding these differences helps you select the right machine for tasks requiring either hole creation or refinement.

Construction and Design Comparison

A boring mill features a horizontal or vertical spindle with a specialized boring head designed for enlarging holes with precision, while a drilling machine is equipped with a fixed vertical spindle and drill bits primarily for creating new holes. The boring mill's robust construction includes a heavy-duty worktable and adjustable arm for supporting large, heavy workpieces, contrasting with the drilling machine's simpler frame optimized for smaller components. Design-wise, boring mills offer greater rigidity and versatility for fine-tuning hole diameters, whereas drilling machines emphasize speed and ease of operation for basic hole-drilling tasks.

Principle of Operation: Boring vs Drilling

Boring machines operate by enlarging existing holes using a single-point cutting tool that moves along the hole's axis to achieve precise dimensions and surface finish. Drilling machines create holes by rotating a multi-point drill bit that removes material axially to form the initial hole. The key difference lies in boring's focus on precision enlargement and finishing, whereas drilling primarily forms the hole's initial shape and size.

Typical Applications and Use Cases

Boring mills are primarily used for enlarging existing holes and achieving high precision in machining large or heavy workpieces, making them ideal for applications like engine cylinder blocks, heavy machinery parts, and aerospace components. Drilling machines excel at creating new holes through various materials quickly and efficiently, commonly utilized in construction, metal fabrication, and woodworking industries. Choosing between a boring mill and a drilling machine depends on whether Your project requires precision hole finishing or initial hole creation in the workflow.

Accuracy and Precision: Which Machine Excels?

Boring mills excel in accuracy and precision by allowing fine adjustments to the cutting tool, enabling precise enlargements and finishing of pre-drilled holes with minimal tolerance deviations. Drilling machines provide faster hole creation but typically offer less control over exact dimensions and surface finish compared to boring mills. For applications requiring high precision and tight tolerances, boring mills are the preferred choice over drilling machines.

Material Compatibility and Workpiece Size

Boring mills excel in machining large, heavy workpieces made from cast iron, steel, and alloys, offering precise internal diameter finishing beyond the capability of drilling machines. Drilling machines are versatile for smaller to medium-sized materials such as aluminum, plastics, and softer metals, suited for creating holes rather than enlarging them. The capacity of boring mills to handle larger workpieces with higher rigidity makes them ideal for heavy industrial applications, whereas drilling machines serve well in general-purpose, lighter manufacturing tasks.

Efficiency, Speed, and Productivity Factors

Boring mills offer higher precision and are more efficient for enlarging existing holes with complex geometries, enhancing productivity in heavy-duty machining tasks. Drilling machines provide faster operation speeds for creating new holes but often require secondary processes for finishing, which can reduce overall efficiency. Choosing between the two depends on specific production requirements, where boring mills excel in accuracy and finishing, while drilling machines prioritize speed and initial hole creation.

Cost Considerations and Maintenance Requirements

Boring mills generally have a higher initial cost compared to drilling machines due to their complex structure and precision capabilities, which may impact your budget planning. Maintenance of boring mills requires regular calibration and lubrication to ensure accuracy, making it more intensive and potentially costlier than the simpler upkeep of drilling machines. Drilling machines typically demand less maintenance and lower operational expenses, making them more economical for basic hole-making tasks.

Choosing the Right Machine for Your Needs

Selecting between a boring mill and a drilling machine depends on the precision and type of hole required in your project. Boring mills excel at enlarging and finishing pre-drilled holes with high accuracy and surface quality, ideal for large or complex workpieces. Drilling machines are best suited for creating initial holes quickly and efficiently, especially in smaller or simpler materials.

Boring mill vs drilling machine Infographic

libmatt.com

libmatt.com