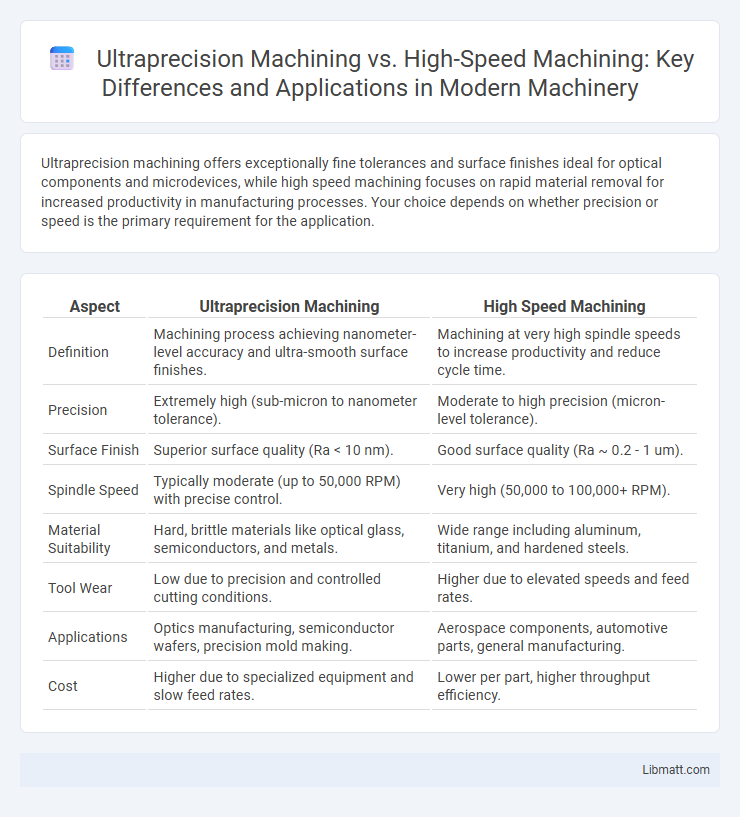

Ultraprecision machining offers exceptionally fine tolerances and surface finishes ideal for optical components and microdevices, while high speed machining focuses on rapid material removal for increased productivity in manufacturing processes. Your choice depends on whether precision or speed is the primary requirement for the application.

Table of Comparison

| Aspect | Ultraprecision Machining | High Speed Machining |

|---|---|---|

| Definition | Machining process achieving nanometer-level accuracy and ultra-smooth surface finishes. | Machining at very high spindle speeds to increase productivity and reduce cycle time. |

| Precision | Extremely high (sub-micron to nanometer tolerance). | Moderate to high precision (micron-level tolerance). |

| Surface Finish | Superior surface quality (Ra < 10 nm). | Good surface quality (Ra ~ 0.2 - 1 um). |

| Spindle Speed | Typically moderate (up to 50,000 RPM) with precise control. | Very high (50,000 to 100,000+ RPM). |

| Material Suitability | Hard, brittle materials like optical glass, semiconductors, and metals. | Wide range including aluminum, titanium, and hardened steels. |

| Tool Wear | Low due to precision and controlled cutting conditions. | Higher due to elevated speeds and feed rates. |

| Applications | Optics manufacturing, semiconductor wafers, precision mold making. | Aerospace components, automotive parts, general manufacturing. |

| Cost | Higher due to specialized equipment and slow feed rates. | Lower per part, higher throughput efficiency. |

Understanding Ultraprecision Machining

Ultraprecision machining achieves sub-micron accuracy by utilizing advanced technologies like computer numerical control (CNC) systems, diamond cutting tools, and vibration isolation platforms to create exceptionally smooth surfaces and complex shapes. Unlike high speed machining, which emphasizes rapid material removal and efficiency, ultraprecision machining focuses on achieving the highest dimensional accuracy and surface finish quality crucial for optics, aerospace, and semiconductor industries. Understanding ultraprecision machining helps you select the right process for applications requiring extreme precision and minimal tolerances.

Defining High Speed Machining

High Speed Machining (HSM) involves cutting materials at significantly increased spindle speeds and feed rates compared to conventional machining, enabling faster material removal and enhanced productivity. This process relies on advanced machine tools with rigid structures and precise control systems to maintain accuracy at high velocities. Understanding HSM's ability to reduce cycle times while maintaining surface quality is essential when comparing it to Ultraprecision Machining, which prioritizes nanometer-level precision over speed.

Key Differences Between Ultraprecision and High Speed Machining

Ultraprecision machining achieves nanometer-level accuracy and surface finishes, essential for optical components and semiconductor devices, while high speed machining prioritizes increased material removal rates and reduced cycle times for mass production. The cutting speeds in ultraprecision machining are significantly lower to maintain extreme dimensional control, whereas high speed machining uses elevated spindle speeds and feed rates to enhance productivity. Your choice between these methods depends on the required precision and production volume, balancing ultra-fine surface quality against manufacturing efficiency.

Material Suitability in Each Machining Method

Ultraprecision machining excels in working with brittle materials such as glass, ceramics, and single-crystal metals, achieving nanometer-level surface finishes and tight dimensional tolerances. High speed machining is more suitable for ductile metals like aluminum, titanium, and hardened steels, enabling rapid material removal with good surface quality. Selecting the appropriate method depends on material hardness, thermal sensitivity, and the desired surface precision.

Tolerance and Surface Finish Capabilities

Ultraprecision machining achieves tolerances within the nanometer range and surface finishes with roughness values as low as 1 nanometer Ra, making it ideal for optical and semiconductor components. High speed machining typically attains tolerances in the micrometer range and surface finishes around 0.2 to 0.8 micrometers Ra, suitable for rapid production of aerospace and automotive parts. The superior control in ultraprecision machining results from advanced feedback systems and vibration isolation, enabling unmatched accuracy and mirror-like surface quality.

Technological Requirements and Equipment Used

Ultraprecision machining demands specialized equipment such as diamond turning machines, air-bearing spindles, and vibration isolation systems to achieve nanometer-level surface finishes and tolerances. High speed machining relies on high-power spindle motors, robust toolholders, and advanced cooling systems to handle rapid cutting speeds while maintaining tool life and dimensional accuracy. Your choice between these technologies depends on the required precision level and the capabilities of the machining equipment available.

Application Sectors for Ultraprecision Machining

Ultraprecision machining is extensively utilized in aerospace, semiconductor manufacturing, and optical industries, where nanometer-level surface finishes and sub-micrometer accuracies are critical. This technique enables the production of complex components for advanced optical lenses, semiconductor wafers, and aerospace engine parts, demanding extreme precision and surface integrity. The medical sector also benefits from ultraprecision machining to fabricate intricate surgical instruments and implants requiring ultra-smooth surfaces and tight tolerances.

High Speed Machining Applications and Advantages

High Speed Machining (HSM) excels in aerospace, automotive, and mold-making industries due to its ability to achieve rapid material removal rates with enhanced surface finishes. HSM reduces cycle times significantly by operating at elevated spindle speeds and feed rates while maintaining precision, leading to increased production efficiency. The process also minimizes thermal distortion and tool wear, making it ideal for machining complex geometries in hard materials.

Cost Considerations and Productivity Factors

Ultraprecision machining demands higher initial investment due to specialized equipment and stringent environmental controls, but it achieves superior surface finishes and tolerances, reducing downstream processing costs. High speed machining offers greater productivity with faster cycle times and increased material removal rates, lowering per-part costs for large volume production. Cost-effectiveness depends on application precision needs versus production volume, where ultraprecision suits low-volume, high-complexity parts and high speed machining benefits high-volume, less critical components.

Future Trends in Precision and Speed Machining Technologies

Ultraprecision machining is advancing with enhanced nanometer-level accuracy through adaptive control systems and real-time monitoring, suited for aerospace and medical device manufacturing. High speed machining is evolving via improved spindle technologies and advanced tool materials, enabling faster cycle times and higher material removal rates in automotive and electronics industries. Integration of AI-driven process optimization and hybrid machining techniques is expected to converge both methods, pushing the boundaries of precision and throughput in future manufacturing environments.

Ultraprecision machining vs high speed machining Infographic

libmatt.com

libmatt.com