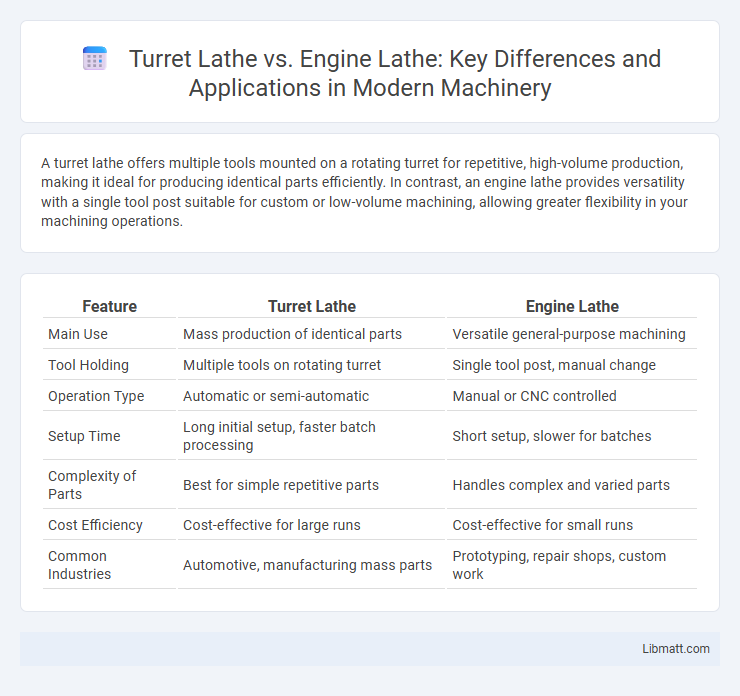

A turret lathe offers multiple tools mounted on a rotating turret for repetitive, high-volume production, making it ideal for producing identical parts efficiently. In contrast, an engine lathe provides versatility with a single tool post suitable for custom or low-volume machining, allowing greater flexibility in your machining operations.

Table of Comparison

| Feature | Turret Lathe | Engine Lathe |

|---|---|---|

| Main Use | Mass production of identical parts | Versatile general-purpose machining |

| Tool Holding | Multiple tools on rotating turret | Single tool post, manual change |

| Operation Type | Automatic or semi-automatic | Manual or CNC controlled |

| Setup Time | Long initial setup, faster batch processing | Short setup, slower for batches |

| Complexity of Parts | Best for simple repetitive parts | Handles complex and varied parts |

| Cost Efficiency | Cost-effective for large runs | Cost-effective for small runs |

| Common Industries | Automotive, manufacturing mass parts | Prototyping, repair shops, custom work |

Introduction to Turret Lathe and Engine Lathe

Turret lathes and engine lathes are essential machine tools in metalworking, each serving distinct functions. A turret lathe features a rotating turret holding multiple tools, enabling rapid consecutive operations without manual tool changes, ideal for mass production. Engine lathes provide precision turning with a single tool post, offering versatility for custom and intricate machining tasks, making Your choice dependent on production volume and complexity.

Key Differences Between Turret and Engine Lathes

Turret lathes feature a rotating turret with multiple tool stations allowing rapid tool changes ideal for repetitive production work, while engine lathes have a single tool post suited for custom machining and versatile operations. Turret lathes enable faster machining cycles due to their multi-tool capability, whereas engine lathes provide greater flexibility in handling various sizes and shapes of workpieces. The turret lathe's automation and indexing features contrast with the manual setup and operation of engine lathes, defining their distinct applications in manufacturing environments.

Design and Construction Comparison

Turret lathes feature a robust, indexed turret head that allows for rapid tool changes, making them ideal for repetitive production tasks. Engine lathes have a simpler design with a single tool post and a more versatile construction suited for a variety of general turning operations. Your choice depends on whether you prioritize efficiency in mass production (turret lathe) or flexibility in precision machining (engine lathe).

Operational Mechanisms

Turret lathes use a rotating turret to hold multiple cutting tools, allowing rapid tool changes and repetitive production without manual adjustments, optimizing your workflow for complex, multi-step machining operations. Engine lathes rely on a single tool post that requires manual repositioning for each cut, offering greater flexibility for one-off or custom jobs but slower operation in high-volume environments. Understanding these operational mechanisms helps you select the right lathe type based on production speed and machining precision needs.

Versatility and Applications

Turret lathes excel in repetitive production environments due to their ability to rapidly switch tools, making them ideal for manufacturing identical parts with high precision. Engine lathes offer greater versatility for custom machining, allowing you to perform a wide range of operations such as turning, threading, and drilling on various workpieces. Your choice depends on whether you prioritize efficiency in mass production or flexibility for diverse, one-off projects.

Precision and Efficiency

Turret lathes offer enhanced efficiency by enabling rapid tool changes and multiple operations without repositioning the workpiece, making them ideal for repetitive precision tasks in mass production. Engine lathes provide superior precision for custom and complex machining due to their versatile manual control, allowing fine adjustments for intricate workpieces. Combining high repeatability from turret lathes with the detailed accuracy of engine lathes optimizes machining workflows across a variety of industrial applications.

Tooling and Setup Time

Turret lathes feature a rotating turret that allows multiple tools to be pre-loaded and quickly indexed, significantly reducing tooling changeover and setup time compared to engine lathes. Engine lathes require manual tool changes and individual setups for each operation, increasing downtime between machining processes. The increased efficiency in tooling setup makes turret lathes ideal for high-volume production runs with repetitive tasks.

Material Handling Capabilities

Turret lathes excel in material handling by allowing multiple tools to be preset and indexed rapidly, enhancing efficiency in repetitive production tasks and minimizing downtime for tool changes. Engine lathes offer greater versatility in handling diverse workpiece sizes and shapes but typically require manual tool changes, which can slow the machining process. The automated tool indexing in turret lathes provides superior material handling capabilities for high-volume manufacturing compared to the more flexible but slower setup of engine lathes.

Cost and Maintenance Considerations

Turret lathes generally incur higher initial costs and maintenance expenses due to their complex tooling and automation features compared to engine lathes. Engine lathes offer a more cost-effective solution for simpler, lower-volume machining tasks, requiring less frequent servicing and lower spare parts investment. Your choice between the two should consider long-term operational costs alongside upfront purchase prices to optimize budget and efficiency.

Choosing the Right Lathe for Your Workshop

Selecting the right lathe for your workshop hinges on the type of machining tasks and production volume; turret lathes excel in repetitive, high-volume work with quick tool changes, making them ideal for batch production. Engine lathes offer greater versatility and precision for custom, one-off projects, suitable for a wide range of turning operations with adjustable speeds and feeds. Evaluate your workflow needs, operator skill level, and budget to determine whether the specialized efficiency of a turret lathe or the adaptability of an engine lathe best aligns with your shop's goals.

Turret lathe vs engine lathe Infographic

libmatt.com

libmatt.com