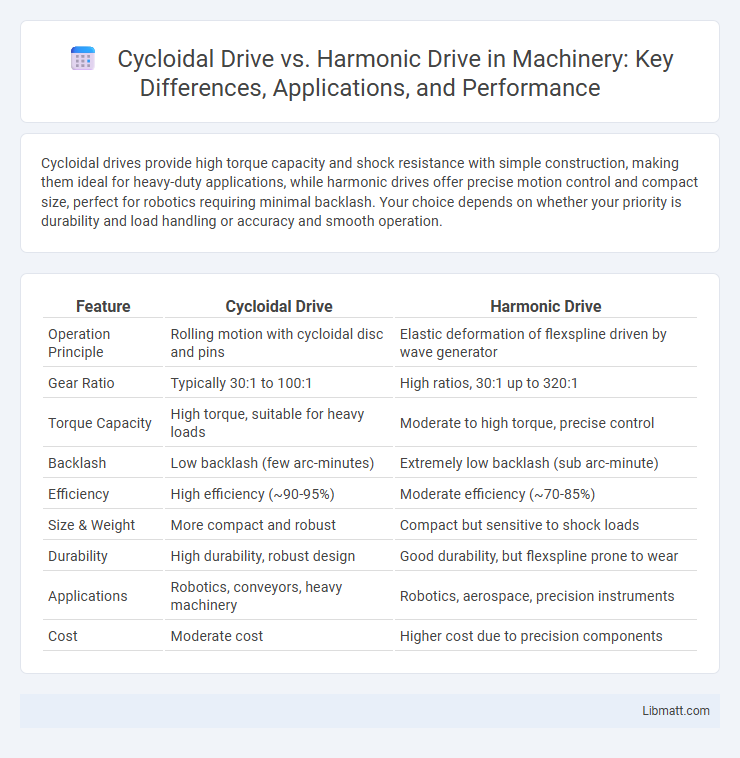

Cycloidal drives provide high torque capacity and shock resistance with simple construction, making them ideal for heavy-duty applications, while harmonic drives offer precise motion control and compact size, perfect for robotics requiring minimal backlash. Your choice depends on whether your priority is durability and load handling or accuracy and smooth operation.

Table of Comparison

| Feature | Cycloidal Drive | Harmonic Drive |

|---|---|---|

| Operation Principle | Rolling motion with cycloidal disc and pins | Elastic deformation of flexspline driven by wave generator |

| Gear Ratio | Typically 30:1 to 100:1 | High ratios, 30:1 up to 320:1 |

| Torque Capacity | High torque, suitable for heavy loads | Moderate to high torque, precise control |

| Backlash | Low backlash (few arc-minutes) | Extremely low backlash (sub arc-minute) |

| Efficiency | High efficiency (~90-95%) | Moderate efficiency (~70-85%) |

| Size & Weight | More compact and robust | Compact but sensitive to shock loads |

| Durability | High durability, robust design | Good durability, but flexspline prone to wear |

| Applications | Robotics, conveyors, heavy machinery | Robotics, aerospace, precision instruments |

| Cost | Moderate cost | Higher cost due to precision components |

Introduction to Cycloidal and Harmonic Drives

Cycloidal drives use an eccentric cam and cycloidal disc to produce smooth, high-torque transmission with minimal backlash, making them ideal for heavy-duty robotics and industrial applications. Harmonic drives rely on a flexible spline and wave generator to achieve precise motion control and zero backlash, commonly used in aerospace and precision machinery. Understanding the fundamental mechanics of these drives helps you select the best solution for high-precision and high-load torque requirements.

Working Principles of Cycloidal Drives

Cycloidal drives operate using a cycloidal disc that rotates eccentrically, engaging with a ring gear to produce high torque and precise motion control through slow speed reduction. The eccentric input shaft causes the cycloidal disc to trace a path that drives output rollers or pins, resulting in smooth power transmission with minimal backlash. This unique mechanism provides high efficiency and durability, making cycloidal drives ideal for heavy-duty applications requiring compact size and reliability.

Working Principles of Harmonic Drives

Harmonic drives operate through the interaction of a flexible spline, circular spline, and wave generator, producing high-precision motion by deforming the flexible spline to engage with the circular spline's teeth. The wave generator, usually an elliptical ball bearing, creates a rotating wave that advances the flexible spline's teeth past the circular spline, generating smooth, high-torque output with minimal backlash. Understanding these working principles helps you select the optimal drive system for applications requiring compact size, high reduction ratios, and exceptional positioning accuracy.

Comparative Efficiency and Performance

Cycloidal drives typically offer higher torque capacity and shock load resistance compared to harmonic drives, making them suitable for heavy-duty applications with better durability. Harmonic drives excel in precision and compactness, delivering minimal backlash and high positional accuracy essential for robotics and aerospace industries. Your choice depends on whether efficiency in torque transmission or supreme precision is the priority for your application's performance.

Torque Capacity and Load Capabilities

Cycloidal drives offer higher torque capacity due to their multiple engagement points distributing load evenly across lobes, allowing them to handle shock loads and radial forces effectively. Harmonic drives provide precise motion with lower backlash but generally have lower torque capacity and more limited load capabilities due to thin flexspline teeth. For heavy-duty applications requiring robust load handling and torque, cycloidal drives outperform harmonic drives in durability and torque transmission.

Backlash and Precision Differences

Cycloidal drives typically exhibit lower backlash than harmonic drives, making them suitable for applications requiring high positional accuracy. Harmonic drives offer exceptional precision with minimal hysteresis but may experience slight backlash due to flexspline deformation under load. The choice between cycloidal and harmonic drives depends on the specific balance needed between backlash reduction and precision in motion control systems.

Durability and Maintenance Requirements

Cycloidal drives offer exceptional durability due to their robust design, which distributes loads evenly across multiple contact points, reducing wear and extending service life. Harmonic drives, while compact and precise, typically require more frequent maintenance because their flexible spline components are prone to fatigue and wear under heavy loads. Your choice depends on whether you prioritize long-term durability with low maintenance (cycloidal) or high precision with potentially higher upkeep (harmonic).

Size, Weight, and Compactness

Cycloidal drives offer a more compact and robust design with fewer moving parts, resulting in lower weight and increased durability compared to harmonic drives. Harmonic drives provide high precision in a smaller form factor but often at the cost of increased complexity and fragility. Your choice depends on the balance between size constraints and operational requirements, with cycloidal drives excelling in heavy-duty, space-limited applications.

Cost and Application Suitability

Cycloidal drives generally offer lower cost and higher durability, making them suitable for heavy-duty industrial applications such as robotics and conveyors. Harmonic drives provide precise motion control and compactness, ideal for aerospace and medical devices where accuracy and smooth torque transmission are critical. Cost-efficiency of cycloidal drives contrasts with the higher precision but premium price point of harmonic drives, influencing the selection based on budget and performance requirements.

Choosing the Right Drive: Key Considerations

Choosing the right drive involves evaluating torque capacity, backlash, efficiency, and durability, where cycloidal drives excel in high torque and shock load resistance while harmonic drives offer superior precision and compactness. Your decision should consider the application's speed requirements, load conditions, and space constraints to optimize performance and lifespan. Factoring in maintenance needs and cost-effectiveness ensures that the chosen drive aligns perfectly with your specific operational demands.

Cycloidal drive vs harmonic drive Infographic

libmatt.com

libmatt.com