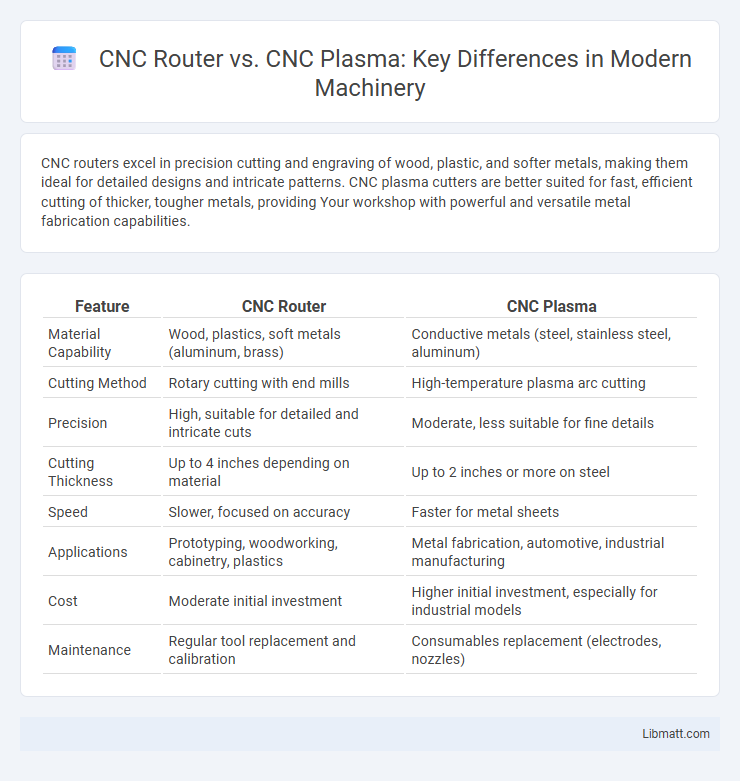

CNC routers excel in precision cutting and engraving of wood, plastic, and softer metals, making them ideal for detailed designs and intricate patterns. CNC plasma cutters are better suited for fast, efficient cutting of thicker, tougher metals, providing Your workshop with powerful and versatile metal fabrication capabilities.

Table of Comparison

| Feature | CNC Router | CNC Plasma |

|---|---|---|

| Material Capability | Wood, plastics, soft metals (aluminum, brass) | Conductive metals (steel, stainless steel, aluminum) |

| Cutting Method | Rotary cutting with end mills | High-temperature plasma arc cutting |

| Precision | High, suitable for detailed and intricate cuts | Moderate, less suitable for fine details |

| Cutting Thickness | Up to 4 inches depending on material | Up to 2 inches or more on steel |

| Speed | Slower, focused on accuracy | Faster for metal sheets |

| Applications | Prototyping, woodworking, cabinetry, plastics | Metal fabrication, automotive, industrial manufacturing |

| Cost | Moderate initial investment | Higher initial investment, especially for industrial models |

| Maintenance | Regular tool replacement and calibration | Consumables replacement (electrodes, nozzles) |

Introduction to CNC Router and CNC Plasma

CNC router and CNC plasma machines are both vital tools in digital fabrication, serving distinct purposes based on materials and cutting methods. CNC routers use rotating cutting tools to carve wood, plastics, and softer metals with high precision, ideal for detailed and complex designs. Your choice depends on the application, with CNC plasma excelling in cutting conductive metals rapidly using ionized gas for intense heat, making it suitable for industrial metal fabrication.

Key Differences Between CNC Router and CNC Plasma

CNC routers use high-speed rotary cutting tools to precisely carve materials like wood, plastic, and soft metals, making them ideal for detailed woodwork and signage. CNC plasma cutters utilize a high-temperature plasma arc to cut through electrically conductive metals such as steel, aluminum, and copper, offering faster cutting speeds and superior performance on thick metal plates. Key differences lie in their cutting mechanisms, compatible materials, thickness capacities, and precision levels, with CNC routers excelling in fine detail and CNC plasma systems providing robust, high-speed metal cutting.

How CNC Routers Work

CNC routers use computer-controlled cutting tools to carve, cut, and shape materials like wood, plastic, and soft metals by following precise digital designs. Your router's spindle rotates at high speeds while the cutting bit moves along multiple axes to create detailed patterns with accuracy. Unlike CNC plasma machines that rely on high-temperature plasma flames to cut through metals, CNC routers mechanically remove material for smooth and intricate finishes.

How CNC Plasma Cutters Operate

CNC plasma cutters operate by utilizing an accelerated jet of hot plasma to cut through electrically conductive materials such as steel, aluminum, and brass. The plasma is created by sending an electric arc through a gas that is passing through a constricted opening, generating temperatures around 25,000degC, which melts the metal precisely along the programmed path. Your choice between CNC plasma and CNC router depends on the material thickness and cutting speed, with plasma excelling in fast, high-precision cuts on thicker metals.

Material Compatibility: Router vs Plasma

CNC routers excel in cutting softer materials like wood, plastics, and aluminum, offering precise and clean edges ideal for detailed projects. CNC plasma systems specialize in cutting electrically conductive metals such as steel, stainless steel, and aluminum, delivering high-speed cuts suitable for thicker materials. Material compatibility significantly influences the choice between CNC routers and plasma cutters based on project requirements and material properties.

Precision and Cutting Quality Comparison

CNC routers deliver superior precision and smoother cutting quality due to their higher spindle speeds and tightly controlled cutting tools, making them ideal for detailed woodworking and plastics. CNC plasma machines excel in cutting thicker metals but offer less precision with rougher edges compared to routers because of the plasma arc's wider kerf and heat-affected zones. For applications requiring fine detail and clean finishes, CNC routers outperform plasma cutters in maintaining tight tolerances and minimal material distortion.

Speed and Efficiency Analysis

CNC routers offer higher precision and faster material removal rates on wood, plastic, and softer metals, making them ideal for detailed engraving and cutting projects with minimal secondary processing. CNC plasma cutters excel in cutting thicker metals at much higher speeds due to their ability to slice through steel plates rapidly, which increases overall productivity in heavy-duty fabrication. Choosing between the two depends on material compatibility and desired cut quality, with CNC plasma providing faster throughput for thick metals while CNC routers deliver superior accuracy and surface finish for lighter materials.

Cost Considerations for Both Machines

CNC routers generally have a lower initial cost compared to CNC plasma machines, making them more accessible for small to medium-sized businesses. Operating expenses for CNC plasma involve higher energy consumption and consumable parts like electrodes and nozzles, increasing long-term costs. In contrast, CNC routers primarily incur maintenance costs related to tool bits and lubrication, often resulting in lower ongoing expenses.

Typical Applications and Use Cases

CNC routers are ideal for woodworking, sign making, and intricate engraving on materials like wood, plastic, and composites, offering high precision for detailed designs. CNC plasma machines excel in cutting thick metals such as steel, aluminum, and stainless steel, commonly used in metal fabrication, automotive repair, and industrial manufacturing. Your choice depends on the material type and the precision required for your specific project.

Choosing the Right CNC Machine for Your Needs

Selecting between a CNC router and a CNC plasma machine depends primarily on the material type and desired precision; CNC routers excel in cutting wood, plastics, and soft metals with high accuracy, while CNC plasma machines are ideal for quickly cutting thick metals like steel and aluminum. CNC routers offer detailed engraving and smoother finishes suitable for furniture and cabinetry, whereas plasma cutters provide faster, more cost-effective solutions for heavy-duty metal fabrication. Evaluating project requirements, including material thickness, finish quality, and production speed, ensures the right CNC machine optimizes productivity and meets specific manufacturing demands.

CNC router vs CNC plasma Infographic

libmatt.com

libmatt.com