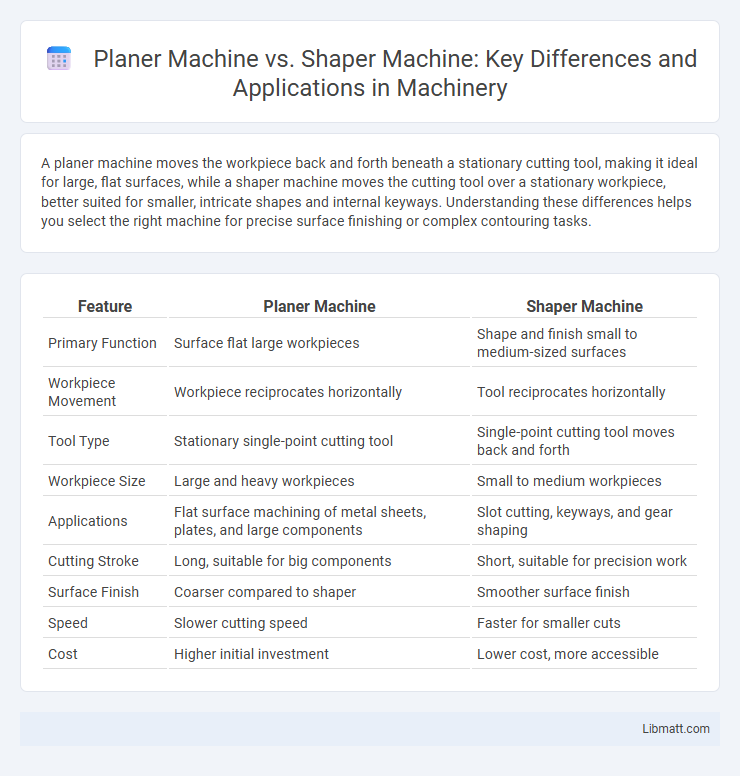

A planer machine moves the workpiece back and forth beneath a stationary cutting tool, making it ideal for large, flat surfaces, while a shaper machine moves the cutting tool over a stationary workpiece, better suited for smaller, intricate shapes and internal keyways. Understanding these differences helps you select the right machine for precise surface finishing or complex contouring tasks.

Table of Comparison

| Feature | Planer Machine | Shaper Machine |

|---|---|---|

| Primary Function | Surface flat large workpieces | Shape and finish small to medium-sized surfaces |

| Workpiece Movement | Workpiece reciprocates horizontally | Tool reciprocates horizontally |

| Tool Type | Stationary single-point cutting tool | Single-point cutting tool moves back and forth |

| Workpiece Size | Large and heavy workpieces | Small to medium workpieces |

| Applications | Flat surface machining of metal sheets, plates, and large components | Slot cutting, keyways, and gear shaping |

| Cutting Stroke | Long, suitable for big components | Short, suitable for precision work |

| Surface Finish | Coarser compared to shaper | Smoother surface finish |

| Speed | Slower cutting speed | Faster for smaller cuts |

| Cost | Higher initial investment | Lower cost, more accessible |

Introduction to Planer and Shaper Machines

Planer machines operate with a stationary workpiece and a moving cutting tool, ideal for producing flat surfaces on large plates or slabs. Shaper machines feature a moving tool that performs a reciprocating motion against a fixed workpiece, commonly used for shaping smaller, intricate parts and profiles. Your choice between the two depends on the size and complexity of the job, with planers suited for heavy-duty shaping and shapers optimized for precision and detail.

Overview of Planer Machine

A planer machine is a metalworking tool designed to produce flat surfaces by moving the workpiece back and forth under a stationary cutting tool, making it ideal for large and heavy workpieces. It operates with a reciprocating table that provides linear motion, allowing precise removal of material layer by layer. Planer machines offer excellent accuracy and surface finish for machining large components such as machine beds and large panels.

Overview of Shaper Machine

A shaper machine is a metalworking tool designed to produce flat surfaces, grooves, and keyways by moving a single-point cutting tool linearly over the workpiece. It operates with a reciprocating ram that holds the cutting tool, offering precise control for machining irregular shapes and internal splines. Shaper machines are ideal for light to medium work, providing versatility and cost-effectiveness compared to planer machines, which are better suited for larger, heavier workpieces.

Working Principle: Planer vs Shaper

The planer machine operates by moving the workpiece linearly against a single-point cutting tool fixed in position, allowing the entire surface to be machined with each pass. In contrast, the shaper machine uses a reciprocating cutting tool that moves back and forth over a stationary workpiece, removing material primarily during the forward stroke. This fundamental difference in motion defines their suitability for machining large flat surfaces (planer) versus smaller, intricate profiles and contours (shaper).

Key Differences Between Planer and Shaper Machines

Planer machines are designed for processing large, flat surfaces by moving the workpiece back and forth beneath a stationary cutting tool, while shaper machines use a single-point cutting tool that moves linearly over a stationary workpiece. Planers are typically larger, suitable for heavy-duty applications with workpieces that exceed the tool size, whereas shapers are ideal for smaller, precise cuts on workpieces. The main distinction lies in the workpiece movement in planers versus tool movement in shapers, influencing their applications and size capabilities.

Construction and Design Comparison

Planer machines feature a massive bed where the workpiece remains stationary while the cutting tool moves horizontally, utilizing a robust frame and dual cross rails for stability. In contrast, shaper machines have a fixed tool with a vertical ram that moves back and forth, supported by a smaller, more compact column and table setup. Your choice depends on the size and complexity of the workpiece, with planers suited for larger surfaces and shapers for smaller, detailed cuts due to their distinct construction and design.

Application Areas for Each Machine

Planer machines are primarily used for large, flat surfaces on heavy and bulky workpieces such as machine beds, large panels, and engine blocks, ideal for industries like shipbuilding and heavy machinery manufacturing. Shaper machines are best suited for creating smaller, intricate shapes and slots on workpieces like keyways, grooves, and complex contours, commonly utilized in tool rooms and workshops for precision metalworking. Your choice depends on the size and complexity of the workpiece, with planers excelling in large-scale surface shaping and shapers excelling in detailed finishing and shaping tasks.

Advantages and Disadvantages

Planer machines offer the advantage of handling large and heavy workpieces with high precision, ideal for flat surface machining over long lengths. However, they tend to have slower operation speeds and higher operational costs compared to shaper machines. Shaper machines excel in lower-cost setups and simpler maintenance, but they are limited in workpiece size and generally less suitable for extensive flat surface processing.

Factors to Consider When Choosing

When choosing between a planer machine and a shaper machine, factors such as the size and type of workpiece, required surface finish, and the complexity of the cutting operation are crucial. Planer machines are better suited for large, flat surfaces and heavy-duty work, while shaper machines excel in producing smaller, intricate shapes with precision. Consider machine capacity, speed control, and tooling options to match specific manufacturing needs and ensure optimal productivity.

Summary and Final Recommendations

Planer machines excel in handling large, heavy workpieces with linear motions, ideal for flat surface machining over long lengths, while shaper machines are better suited for smaller workpieces requiring precise cuts with a single-point cutting tool. For industrial-scale applications needing extensive material removal on broad surfaces, planers provide superior efficiency and stability. Choose shaper machines for detailed, intricate shaping tasks and budget-conscious workshops seeking versatile, low-maintenance equipment.

Planer machine vs shaper machine Infographic

libmatt.com

libmatt.com