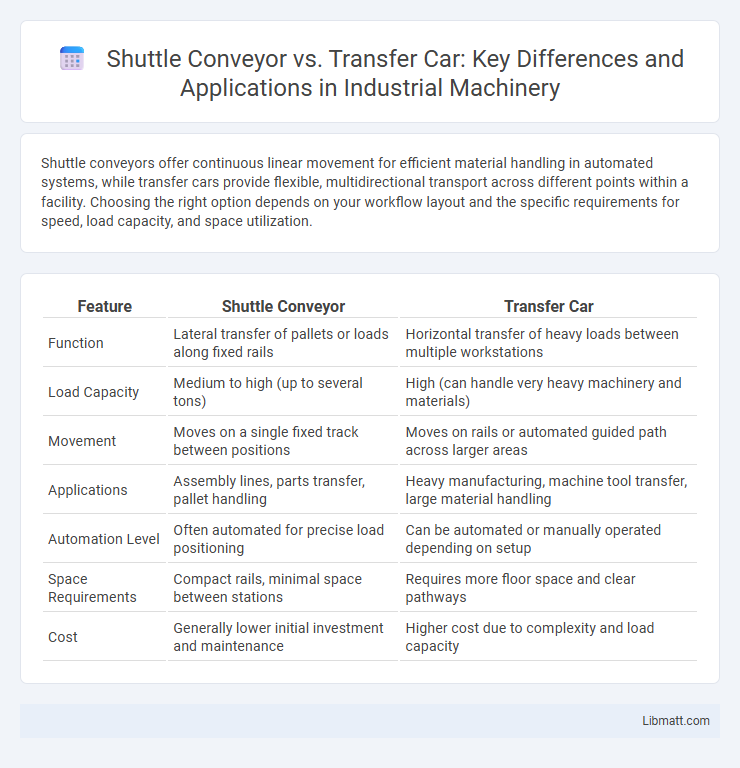

Shuttle conveyors offer continuous linear movement for efficient material handling in automated systems, while transfer cars provide flexible, multidirectional transport across different points within a facility. Choosing the right option depends on your workflow layout and the specific requirements for speed, load capacity, and space utilization.

Table of Comparison

| Feature | Shuttle Conveyor | Transfer Car |

|---|---|---|

| Function | Lateral transfer of pallets or loads along fixed rails | Horizontal transfer of heavy loads between multiple workstations |

| Load Capacity | Medium to high (up to several tons) | High (can handle very heavy machinery and materials) |

| Movement | Moves on a single fixed track between positions | Moves on rails or automated guided path across larger areas |

| Applications | Assembly lines, parts transfer, pallet handling | Heavy manufacturing, machine tool transfer, large material handling |

| Automation Level | Often automated for precise load positioning | Can be automated or manually operated depending on setup |

| Space Requirements | Compact rails, minimal space between stations | Requires more floor space and clear pathways |

| Cost | Generally lower initial investment and maintenance | Higher cost due to complexity and load capacity |

Introduction to Shuttle Conveyors and Transfer Cars

Shuttle conveyors and transfer cars both serve essential roles in material handling and logistics automation, streamlining the movement of goods within warehouses and manufacturing facilities. Shuttle conveyors operate using a motorized shuttle that moves loads laterally between multiple pick-up and drop-off points, optimizing storage density and retrieval speed. Transfer cars, on the other hand, transport heavy or bulky items across fixed rails, providing flexible, horizontal movement for larger-scale operations that require precise positioning of your inventory.

Core Functions and Applications

Shuttle conveyors excel at transporting materials efficiently within confined spaces by moving pallets or containers along a fixed, linear path ideal for automated storage and retrieval systems. Transfer cars provide flexible, multi-directional material handling across different areas in manufacturing or warehouse environments, capable of moving heavy loads on rails or tracks to connect various production lines. Your choice depends on the need for high-speed, repetitive conveyance (shuttle conveyor) versus versatile, large-scale transfer of goods between distinct processing stations (transfer car).

Key Structural Differences

Shuttle conveyors feature a linear sliding motion along fixed rails for efficient load transfer within a confined space, while transfer cars operate on a broader rail system allowing multidirectional movement across multiple lanes or aisles. Your choice depends on whether you need compact, single-axis transport (shuttle conveyor) or versatile, large-area material handling (transfer car). The shuttle conveyor's compact frame contrasts with the transfer car's heavier-duty chassis designed for higher payloads and complex navigation.

Material Handling Capabilities

Shuttle conveyors excel in rapid, precise material handling for lightweight to medium loads, enabling efficient horizontal and limited vertical movement within compact areas. Transfer cars offer heavy-duty capacity, capable of transporting bulky or oversized materials across longer distances on fixed tracks, often integrating with automated storage and retrieval systems. Your choice depends on the volume, weight, and layout requirements of the material handling process.

Efficiency and Speed Comparison

Shuttle conveyors offer higher efficiency and faster load/unload cycles through automated, continuous horizontal movement of materials within a fixed path. Transfer cars provide versatility in routing and can handle multiple lanes but typically operate at slower speeds due to frequent stops and direction changes. Your choice depends on prioritizing rapid, streamlined material flow with shuttle conveyors or flexible routing with transfer cars.

Space Utilization and Layout Flexibility

Shuttle conveyors excel in space utilization by enabling dense, multi-level storage configurations that maximize vertical and horizontal warehouse capacity. Transfer cars offer exceptional layout flexibility, seamlessly moving goods between non-linear paths and integrating with various storage and production systems. Optimizing your facility's design depends on balancing shuttle conveyors' compact storage benefits with transfer cars' adaptable routing capabilities.

Maintenance and Operational Costs

Shuttle conveyors generally incur lower maintenance costs due to fewer moving parts and simpler mechanical structures compared to transfer cars, which require regular upkeep of wheels, motors, and guidance systems. Operational costs for shuttle conveyors remain minimal, benefiting from energy-efficient motors and automated control systems, whereas transfer cars demand higher energy consumption and labor input for navigation and load handling. Over time, the reduced downtime and streamlined maintenance schedules of shuttle conveyors significantly lower total cost of ownership compared to transfer cars.

Safety Features and Risk Mitigation

Shuttle conveyors incorporate advanced safety features such as emergency stop sensors, anti-collision technology, and automated load monitoring systems that reduce operational risks by preventing overloading and collisions. Transfer cars enhance risk mitigation through robust braking systems, safety barriers, and real-time tracking to ensure precise movement and avoid accidents in complex logistics environments. Both systems prioritize worker safety and asset protection by integrating fail-safe mechanisms and compliance with industrial safety standards.

Industry-Specific Use Cases

Shuttle conveyors are widely used in warehousing and e-commerce industries for high-speed, automated order fulfillment and efficient storage retrieval systems. Transfer cars are preferred in heavy manufacturing sectors such as automotive and steel production, where they transport large, heavy loads across expansive factory floors. Both solutions integrate into smart factories but serve distinct roles based on load type and material flow complexity.

Choosing the Right System for Your Needs

Shuttle conveyors offer highly efficient, automated transport solutions for repetitive, fixed-route material movement, ideal for high-throughput environments requiring precise load handling. Transfer cars provide versatile, flexible transport across multiple routes and can handle larger or irregular loads, fitting complex layouts with variable destination points. Assess your facility's layout, load types, and throughput demands to determine whether the shuttle conveyor's speed or the transfer car's adaptability best aligns with Your operational efficiency goals.

Shuttle conveyor vs transfer car Infographic

libmatt.com

libmatt.com