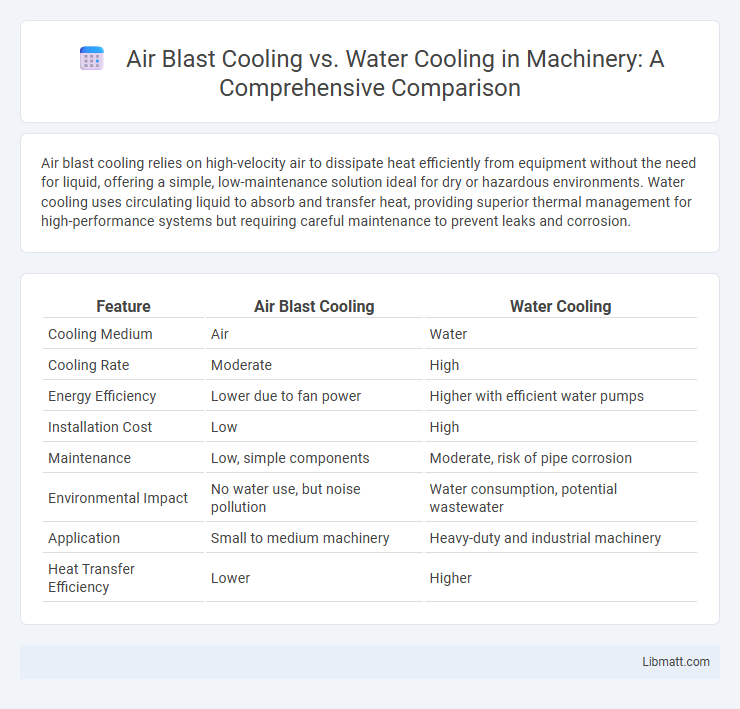

Air blast cooling relies on high-velocity air to dissipate heat efficiently from equipment without the need for liquid, offering a simple, low-maintenance solution ideal for dry or hazardous environments. Water cooling uses circulating liquid to absorb and transfer heat, providing superior thermal management for high-performance systems but requiring careful maintenance to prevent leaks and corrosion.

Table of Comparison

| Feature | Air Blast Cooling | Water Cooling |

|---|---|---|

| Cooling Medium | Air | Water |

| Cooling Rate | Moderate | High |

| Energy Efficiency | Lower due to fan power | Higher with efficient water pumps |

| Installation Cost | Low | High |

| Maintenance | Low, simple components | Moderate, risk of pipe corrosion |

| Environmental Impact | No water use, but noise pollution | Water consumption, potential wastewater |

| Application | Small to medium machinery | Heavy-duty and industrial machinery |

| Heat Transfer Efficiency | Lower | Higher |

Introduction to Cooling Systems

Air blast cooling relies on high-velocity air jets to dissipate heat efficiently from surfaces and electronic components, making it ideal for applications where water usage is restricted. Water cooling employs liquid circulation to absorb and transfer heat away from critical systems, offering superior thermal management in high-performance environments such as data centers and industrial machinery. Both systems are fundamental in maintaining optimal operational temperatures, directly impacting the reliability and longevity of equipment.

Overview of Air Blast Cooling

Air blast cooling utilizes high-velocity air streams directed at components to dissipate heat efficiently, enhancing thermal management in electronic devices and industrial machinery. This method offers advantages such as lower maintenance costs and environmental benefits due to the absence of liquid coolants. Its effectiveness depends on airflow design, ambient conditions, and component surface area, making it ideal for applications where liquid cooling may pose risks or complexity.

Overview of Water Cooling

Water cooling uses liquid coolant circulated through tubes and a radiator to efficiently dissipate heat from components, providing superior thermal management compared to air blast cooling. This method reduces operating temperatures significantly, enhancing performance and hardware longevity in high-power systems. If you seek optimal cooling for your PC or industrial equipment, water cooling offers quieter operation and better heat transfer efficiency.

Key Differences Between Air Blast and Water Cooling

Air blast cooling uses high-velocity air jets to rapidly reduce temperature by increasing heat dissipation, while water cooling relies on liquid coolant circulating through tubes to absorb and transfer heat away efficiently. The key differences include cooling efficiency, with water cooling generally offering superior thermal conductivity and temperature control compared to air blast cooling's simplicity and lower operational cost. Your choice depends on system requirements, as air blast is favored for ease of maintenance and lower initial investment, whereas water cooling excels in high-performance or densely packed electronic applications.

Efficiency Comparison: Air Blast vs Water Cooling

Water cooling systems generally offer higher efficiency than air blast cooling due to superior heat transfer properties of water, enabling faster dissipation of thermal energy from components. Air blast cooling relies on forced air convection, which is less effective in removing heat, especially under high thermal loads or compact environments. The efficiency gap widens as operating temperatures and power densities increase, making water cooling preferable for high-performance applications requiring precise thermal management.

Cost Analysis: Installation and Maintenance

Air blast cooling typically offers lower installation costs due to simpler infrastructure and the absence of complex piping systems, making it cost-effective for small to medium-scale applications. Maintenance expenses are generally reduced since air cooling systems avoid water treatment and corrosion issues, but efficiency can drop in high ambient temperatures. Water cooling systems require higher initial investment for pumps, cooling towers, and piping, alongside ongoing costs for water procurement and chemical treatments, but they provide superior thermal performance in environments with high heat loads.

Environmental Impact and Sustainability

Air blast cooling significantly reduces water consumption compared to water cooling, making it an environmentally sustainable choice, especially in water-scarce regions. Water cooling systems often lead to high water usage and potential thermal pollution, which can disrupt aquatic ecosystems and increase environmental strain. You can lower your carbon footprint by opting for air blast cooling, which relies on ambient air, minimizing resource depletion and wastewater generation.

Application Suitability for Each Cooling Method

Air blast cooling excels in applications requiring rapid temperature reduction of hot metals in industries such as steelmaking and forging, where precise control over cooling rates influences material properties. Water cooling is better suited for scenarios demanding high heat dissipation, like power plants and heavy machinery, providing efficient temperature regulation through direct contact with water. Your choice depends on factors like cooling speed, environmental impact, and equipment design, ensuring optimal performance in specific industrial processes.

Pros and Cons of Air Blast Cooling

Air blast cooling offers advantages such as lower maintenance costs and no risk of water leakage compared to water cooling systems, making it suitable for environments where water supply is limited. Its effectiveness decreases in high ambient temperatures, and it generally provides less efficient thermal management than water cooling, which uses liquid to remove heat more rapidly. You should consider air blast cooling if you need a simpler, more cost-effective solution but be aware of its limitations in cooling performance for high-power equipment.

Pros and Cons of Water Cooling

Water cooling offers superior heat dissipation compared to air blast cooling, enabling higher component performance and quieter operation due to efficient thermal transfer through liquid. Its major drawbacks include the potential for leaks, higher initial setup costs, and complexity in installation and maintenance. Despite these challenges, water cooling remains essential for high-performance computing and overclocking applications where effective temperature control is critical.

Air blast cooling vs water cooling Infographic

libmatt.com

libmatt.com