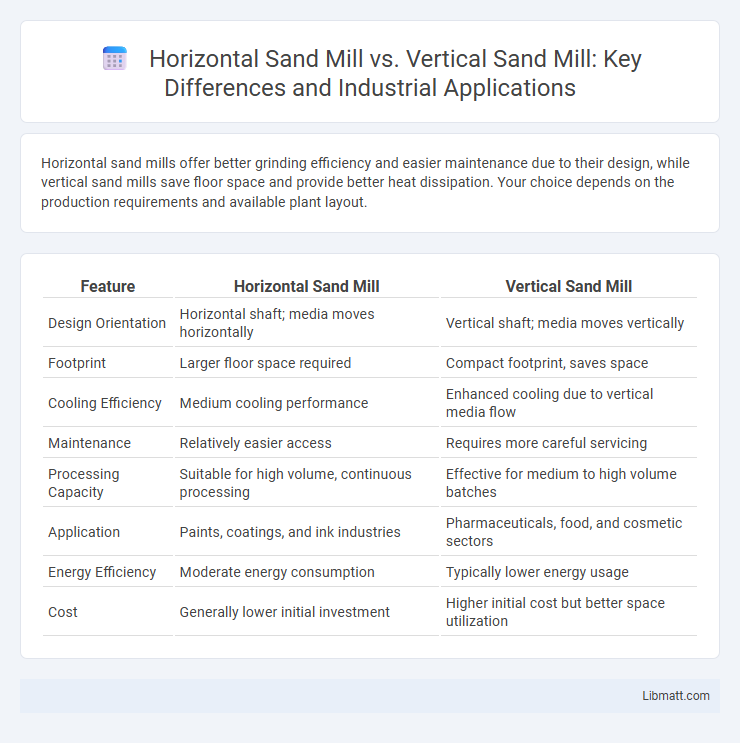

Horizontal sand mills offer better grinding efficiency and easier maintenance due to their design, while vertical sand mills save floor space and provide better heat dissipation. Your choice depends on the production requirements and available plant layout.

Table of Comparison

| Feature | Horizontal Sand Mill | Vertical Sand Mill |

|---|---|---|

| Design Orientation | Horizontal shaft; media moves horizontally | Vertical shaft; media moves vertically |

| Footprint | Larger floor space required | Compact footprint, saves space |

| Cooling Efficiency | Medium cooling performance | Enhanced cooling due to vertical media flow |

| Maintenance | Relatively easier access | Requires more careful servicing |

| Processing Capacity | Suitable for high volume, continuous processing | Effective for medium to high volume batches |

| Application | Paints, coatings, and ink industries | Pharmaceuticals, food, and cosmetic sectors |

| Energy Efficiency | Moderate energy consumption | Typically lower energy usage |

| Cost | Generally lower initial investment | Higher initial cost but better space utilization |

Introduction to Sand Mills

Horizontal sand mills offer efficient wet grinding with a horizontal cylindrical design that maximizes contact between media and material, enhancing dispersion quality. Vertical sand mills feature a vertical shaft and compact footprint, providing superior heat dissipation and easier maintenance in confined spaces. Choosing the right sand mill depends on your specific production needs, material characteristics, and floor space availability.

Overview of Horizontal Sand Mills

Horizontal sand mills feature a horizontally oriented grinding chamber that allows efficient dispersion of fine particles using high-speed rotating beads, making them ideal for producing high-quality inks, coatings, and paints. These mills offer uniform particle size reduction with excellent heat dissipation due to their horizontal design, ensuring consistent product quality in large-scale industrial applications. The horizontal configuration simplifies maintenance and cleaning, which enhances operational uptime and reduces downtime compared to vertical sand mills.

Overview of Vertical Sand Mills

Vertical sand mills feature a space-saving design that positions the grinding chamber vertically, enhancing energy efficiency and heat dissipation during processing. This configuration allows for better control over particle size distribution and improved throughput in fine grinding applications. You can expect vertical sand mills to provide consistent product quality with lower maintenance requirements compared to horizontal sand mills.

Key Design Differences

Horizontal sand mills feature a horizontal grinding chamber where the milling media moves parallel to the material flow, enhancing mixing efficiency and cooling. Vertical sand mills have a vertical orientation with media moving vertically, promoting better circulation and uniform grinding. The design difference influences energy consumption, maintenance accessibility, and suitability for various slurry viscosities.

Grinding Efficiency Comparison

Horizontal sand mills generally offer higher grinding efficiency due to better circulation and mixing of media and slurry, resulting in finer particle size and uniform distribution. Vertical sand mills excel in space-saving design and ease of maintenance but may experience slightly lower energy efficiency compared to horizontal models. Your choice depends on the balance between desired throughput and operational convenience, with horizontal mills favoring maximum grinding performance.

Applications and Suitable Materials

Horizontal sand mills excel in processing abrasive materials like paints, inks, and coatings due to their efficient cooling and consistent grinding action, making them ideal for high-viscosity products. Vertical sand mills are preferred for fine dispersions of sensitive materials such as pharmaceuticals and cosmetics where space-saving design and ease of cleaning are critical. Your choice depends on the application requirements and the material characteristics, with horizontal mills suited for heavy-duty milling and vertical mills optimized for delicate or heat-sensitive substances.

Energy Consumption Analysis

Horizontal sand mills generally consume more energy due to their larger motor capacity and extended processing time required for grinding. Vertical sand mills offer higher energy efficiency by utilizing gravity-assisted media movement, resulting in reduced power usage per unit of output. To optimize your energy costs, choosing a vertical sand mill can lead to significant savings in industrial grinding operations.

Maintenance and Operational Costs

Horizontal sand mills typically incur higher maintenance costs due to more frequent bearing replacements and shaft seal wear, while vertical sand mills benefit from simpler designs that reduce downtime and service expenses. Operational costs for horizontal mills are elevated by greater energy consumption linked to their larger footprint and more complex cooling requirements, whereas vertical sand mills operate more efficiently with lower power usage and streamlined heat dissipation. You can optimize your production budget by choosing vertical sand mills for lower ongoing maintenance and operational expenses.

Pros and Cons of Each Type

Horizontal sand mills offer superior cooling efficiency and easier maintenance due to their design, making them ideal for high-volume production; however, they often require a larger floor footprint and higher energy consumption. Vertical sand mills save space and reduce energy costs with their compact, upright structure but can be more challenging to clean and maintain, which may affect production downtime. Understanding these differences allows you to choose the best mill type based on your operational priorities and space constraints.

Choosing the Right Sand Mill for Your Needs

Horizontal sand mills offer superior cooling efficiency and are ideal for large-scale production due to their ability to handle higher volumes of slurry, whereas vertical sand mills save floor space and are easier to clean, making them suitable for smaller batches and quick color changes. Your choice depends on production scale, space availability, and maintenance preferences, with horizontal models favoring continuous heavy-duty operations and vertical models optimizing flexibility and convenience. Evaluating these factors ensures you select the sand mill that maximizes efficiency and meets your specific industrial processing requirements.

Horizontal sand mill vs vertical sand mill Infographic

libmatt.com

libmatt.com