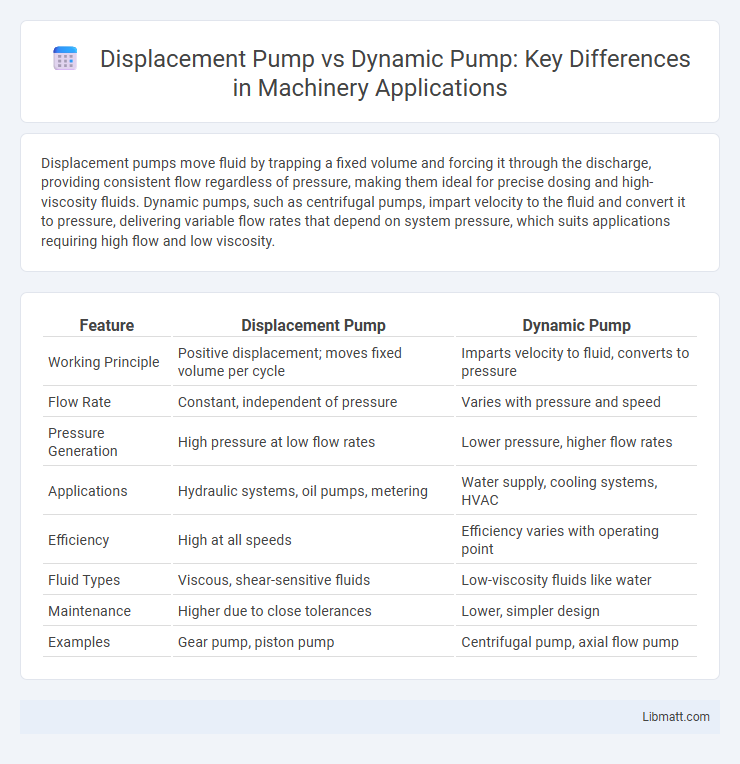

Displacement pumps move fluid by trapping a fixed volume and forcing it through the discharge, providing consistent flow regardless of pressure, making them ideal for precise dosing and high-viscosity fluids. Dynamic pumps, such as centrifugal pumps, impart velocity to the fluid and convert it to pressure, delivering variable flow rates that depend on system pressure, which suits applications requiring high flow and low viscosity.

Table of Comparison

| Feature | Displacement Pump | Dynamic Pump |

|---|---|---|

| Working Principle | Positive displacement; moves fixed volume per cycle | Imparts velocity to fluid, converts to pressure |

| Flow Rate | Constant, independent of pressure | Varies with pressure and speed |

| Pressure Generation | High pressure at low flow rates | Lower pressure, higher flow rates |

| Applications | Hydraulic systems, oil pumps, metering | Water supply, cooling systems, HVAC |

| Efficiency | High at all speeds | Efficiency varies with operating point |

| Fluid Types | Viscous, shear-sensitive fluids | Low-viscosity fluids like water |

| Maintenance | Higher due to close tolerances | Lower, simpler design |

| Examples | Gear pump, piston pump | Centrifugal pump, axial flow pump |

Introduction to Displacement and Dynamic Pumps

Displacement pumps operate by trapping a fixed volume of fluid and forcing it through the discharge, ensuring consistent flow regardless of pressure changes, making them ideal for precise fluid delivery. Dynamic pumps, including centrifugal pumps, rely on kinetic energy to increase fluid velocity and convert it to pressure, suitable for high flow rates and lower pressure applications. Understanding your system's flow and pressure requirements helps determine whether a displacement or dynamic pump best suits your needs for efficient operation.

Key Differences Between Displacement and Dynamic Pumps

Displacement pumps deliver a fixed volume of fluid per cycle, making them ideal for precise flow requirements and high-pressure applications. Dynamic pumps rely on kinetic energy to move fluid, offering variable flow rates and better performance in high flow, low pressure scenarios. Your choice depends on whether consistent volume or varying flow is critical for your system's performance.

Working Principle of Displacement Pumps

Displacement pumps operate by trapping a fixed volume of fluid and then forcing it through the discharge pipe, creating a consistent flow regardless of pressure changes. Your system benefits from positive displacement pumps when precise, steady flow rates are required, as they rely on mechanical components like pistons, gears, or diaphragms to physically move fluid. Unlike dynamic pumps that use velocity and centrifugal force to increase fluid pressure, displacement pumps deliver a fixed volume per cycle, ensuring accuracy in dosing or high-viscosity fluid transfer.

Working Principle of Dynamic Pumps

Dynamic pumps operate based on the principle of converting kinetic energy into pressure energy by rapidly rotating an impeller to accelerate the fluid. The fluid gains velocity as it moves outward from the center of the impeller, creating a high flow rate and continuous discharge. This contrasts with displacement pumps, which trap and mechanically move fixed fluid volumes through a sealed chamber.

Types of Displacement Pumps

Displacement pumps include positive displacement types such as gear pumps, diaphragm pumps, and piston pumps, all designed to move a fixed volume of fluid per cycle, ensuring precise and consistent flow rates. Dynamic pumps, on the other hand, rely on kinetic energy to increase fluid velocity, with centrifugal pumps being the most common type, ideal for high flow rate applications. You should choose a displacement pump when accurate flow control and handling of viscous fluids are critical to your process.

Types of Dynamic Pumps

Dynamic pumps include several types such as centrifugal, axial flow, and mixed flow pumps, each designed to move fluids by imparting kinetic energy through rotating impellers. Centrifugal pumps are widely used for their ability to handle large volumes and moderate pressures, while axial flow pumps are suited for high flow rates with low pressure heads. Understanding these varieties helps you select the right pump for efficient fluid transfer based on your application's specific requirements.

Performance Characteristics Comparison

Displacement pumps deliver a fixed volume of fluid per cycle, offering high efficiency and consistent flow rates ideal for precise applications, while dynamic pumps provide variable flow depending on pressure and speed, excelling in high-flow, low-viscosity scenarios. Displacement pumps maintain steady pressure at low speeds, whereas dynamic pumps experience a drop in pressure performance as fluid velocity increases. Performance characteristics favor displacement pumps for viscosity tolerance and consistent output, while dynamic pumps are preferred for applications requiring higher flow rates and simpler mechanical design.

Applications and Industries Served

Displacement pumps excel in industries requiring precise fluid control, such as chemical processing, oil and gas, and pharmaceuticals, due to their ability to handle viscous and shear-sensitive fluids. Dynamic pumps are widely used in water treatment, HVAC, and power generation, where high flow rates and continuous operation are essential. Both pump types serve critical roles in manufacturing and agriculture, with displacement pumps favored for metering and dosing, while dynamic pumps support irrigation and cooling systems.

Advantages and Limitations

Displacement pumps offer precise flow control and high efficiency in handling viscous fluids, making them ideal for applications requiring consistent volume delivery. Dynamic pumps excel in applications involving high flow rates and low-viscosity liquids but suffer from reduced efficiency under varying pressure conditions. Your choice depends on whether you prioritize accurate fluid metering or handling large volumes at variable pressures.

Choosing the Right Pump for Your Needs

Displacement pumps excel in delivering a consistent flow rate regardless of pressure variations, making them ideal for applications requiring precise fluid control and high viscosity fluids. Dynamic pumps, including centrifugal and axial types, are better suited for high flow rate scenarios with low viscosity liquids and variable pressure conditions due to their ability to handle large volumes efficiently. Choosing the right pump depends on factors such as fluid characteristics, required flow rate, pressure conditions, and system efficiency demands to ensure optimal performance and longevity.

Displacement pump vs dynamic pump Infographic

libmatt.com

libmatt.com