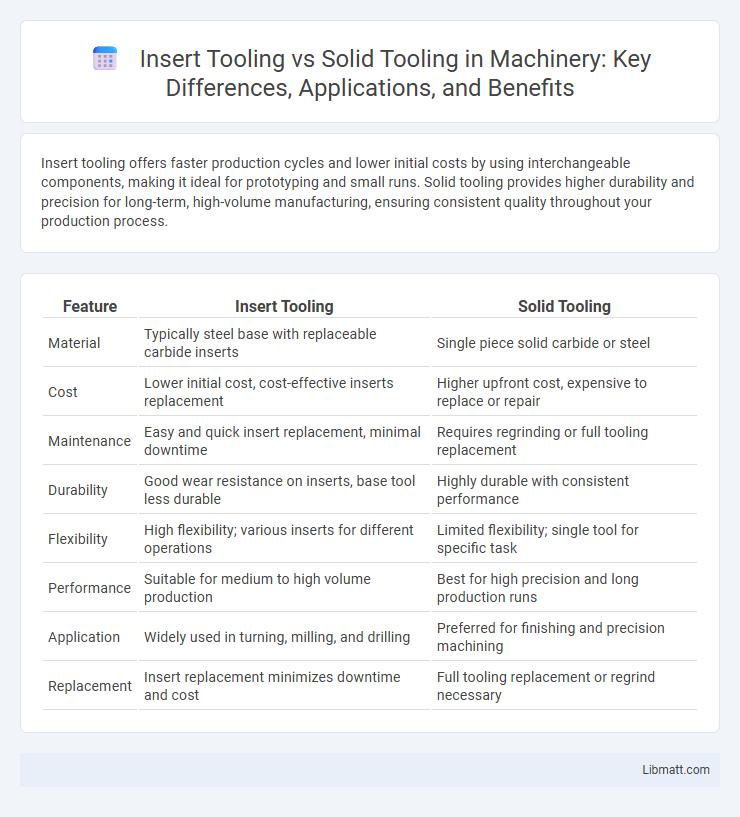

Insert tooling offers faster production cycles and lower initial costs by using interchangeable components, making it ideal for prototyping and small runs. Solid tooling provides higher durability and precision for long-term, high-volume manufacturing, ensuring consistent quality throughout your production process.

Table of Comparison

| Feature | Insert Tooling | Solid Tooling |

|---|---|---|

| Material | Typically steel base with replaceable carbide inserts | Single piece solid carbide or steel |

| Cost | Lower initial cost, cost-effective inserts replacement | Higher upfront cost, expensive to replace or repair |

| Maintenance | Easy and quick insert replacement, minimal downtime | Requires regrinding or full tooling replacement |

| Durability | Good wear resistance on inserts, base tool less durable | Highly durable with consistent performance |

| Flexibility | High flexibility; various inserts for different operations | Limited flexibility; single tool for specific task |

| Performance | Suitable for medium to high volume production | Best for high precision and long production runs |

| Application | Widely used in turning, milling, and drilling | Preferred for finishing and precision machining |

| Replacement | Insert replacement minimizes downtime and cost | Full tooling replacement or regrind necessary |

Introduction to Insert Tooling and Solid Tooling

Insert tooling uses pre-manufactured inserts that are embedded into a mold base, allowing for quick changes and enhanced flexibility in production, making it ideal for short to medium runs. Solid tooling, on the other hand, consists of a single, machined block that offers superior durability and precision for high-volume manufacturing. Understanding the differences helps you choose the right tooling method to optimize cost-efficiency and production speed in your manufacturing process.

Key Differences Between Insert and Solid Tooling

Insert tooling features pre-made components embedded into a mold, offering cost-effective flexibility for complex designs and shorter production runs, while solid tooling consists of a single, solid metal block tailored for high-volume manufacturing with superior durability. Insert tooling allows faster turnaround and easier maintenance by replacing individual inserts, whereas solid tooling requires complete mold changes but delivers enhanced precision and longer lifespan. Your choice depends on production volume, design complexity, and budget, with insert tooling ideal for prototyping and solid tooling suited for large-scale, consistent part manufacturing.

Material Compatibility for Insert and Solid Tooling

Insert tooling offers enhanced material compatibility by allowing interchangeable inserts made from specialized materials such as carbide, steel, or ceramic, which can be tailored to match the specific properties of the workpiece. Solid tooling, typically manufactured from a single material like high-speed steel or hardened steel, may have limitations in handling abrasive or corrosive materials due to uniform wear resistance. The ability of insert tooling to optimize cutting performance for diverse materials improves tool life and reduces downtime compared to solid tooling.

Cost Analysis: Insert Tooling vs Solid Tooling

Insert tooling offers lower initial costs due to modular components that can be replaced individually, reducing upfront investment and maintenance expenses. Solid tooling involves higher upfront costs but provides greater durability and precision for large production runs, often resulting in lower long-term per-part costs. Your decision should weigh the volume of production and budget constraints to optimize cost efficiency between insert and solid tooling.

Performance and Tool Life Comparison

Insert tooling offers enhanced performance with quicker changeovers and consistent precision, making it ideal for high-volume production. Solid tooling provides superior durability and longer tool life in demanding applications due to its one-piece construction and robust materials. Your choice depends on production speed requirements and the need for tool longevity in specific manufacturing processes.

Flexibility and Customization Options

Insert tooling offers greater flexibility and customization options by allowing easy replacement or modification of specific components without changing the entire mold, making it ideal for low to medium production volumes. Solid tooling, typically made from a single block of material, provides limited customization and is better suited for high-volume production where consistent, repeatable parts are required. The ability of insert tooling to adapt quickly to design changes significantly reduces lead time and upfront costs compared to solid tooling.

Maintenance and Tool Changeover Considerations

Insert tooling offers quicker and simpler maintenance since worn inserts can be replaced individually without machining the entire tool, significantly reducing downtime. Solid tooling, while typically more durable, requires more extensive maintenance and longer tool changeover times due to the need for complete tool replacement or regrinding. Efficient tool changeover in insert tooling improves production flexibility and reduces operational costs compared to solid tooling systems.

Typical Applications in Manufacturing

Insert tooling is commonly employed in high-volume manufacturing of complex plastic parts requiring intricate details and tight tolerances, such as automotive components, medical devices, and consumer electronics. Solid tooling suits low- to medium-volume production runs, prototyping, and parts with simpler geometries due to its faster fabrication and lower initial cost. The choice between insert and solid tooling optimizes production efficiency and cost-effectiveness according to part complexity and manufacturing scale.

Environmental Impact and Sustainability

Insert tooling typically has a lower environmental impact due to reduced material usage and shorter manufacturing cycles compared to solid tooling, which requires more raw materials and energy-intensive machining processes. The sustainability of insert tooling benefits from its modular design, allowing only worn inserts to be replaced rather than the entire tool, minimizing waste. Solid tooling, while robust, often results in higher resource consumption and more waste during production and maintenance, making insert tooling a more eco-friendly choice in manufacturing.

Choosing the Right Tooling for Your Operation

Insert tooling offers flexibility and cost-efficiency for short to medium production runs, making it ideal for operations requiring frequent design changes or customization. Solid tooling, known for its durability and precision, excels in high-volume manufacturing where consistent output and longer tool life justify the higher initial investment. Evaluating your production volume, budget constraints, and product complexity will help you determine the optimal tooling choice for maximizing efficiency and quality in your operation.

Insert tooling vs solid tooling Infographic

libmatt.com

libmatt.com