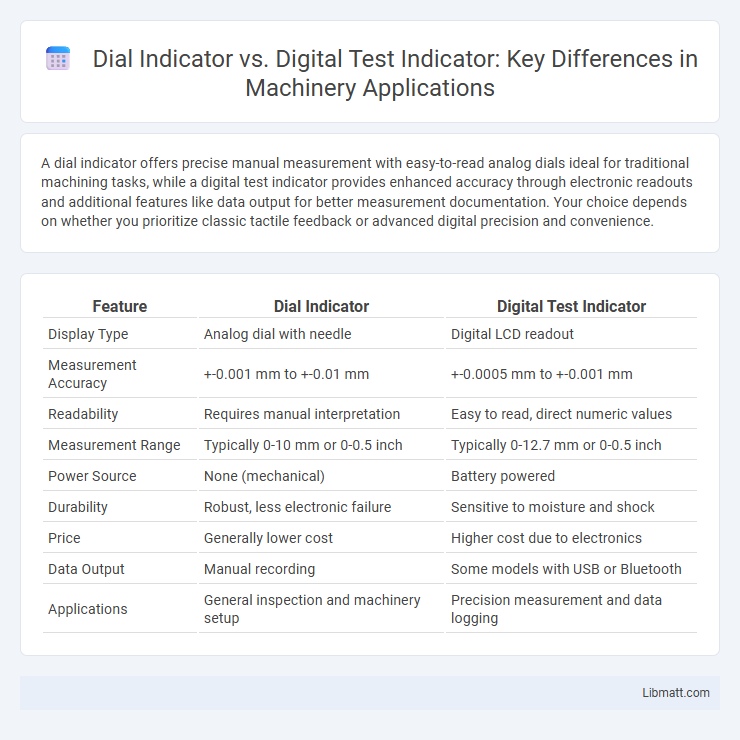

A dial indicator offers precise manual measurement with easy-to-read analog dials ideal for traditional machining tasks, while a digital test indicator provides enhanced accuracy through electronic readouts and additional features like data output for better measurement documentation. Your choice depends on whether you prioritize classic tactile feedback or advanced digital precision and convenience.

Table of Comparison

| Feature | Dial Indicator | Digital Test Indicator |

|---|---|---|

| Display Type | Analog dial with needle | Digital LCD readout |

| Measurement Accuracy | +-0.001 mm to +-0.01 mm | +-0.0005 mm to +-0.001 mm |

| Readability | Requires manual interpretation | Easy to read, direct numeric values |

| Measurement Range | Typically 0-10 mm or 0-0.5 inch | Typically 0-12.7 mm or 0-0.5 inch |

| Power Source | None (mechanical) | Battery powered |

| Durability | Robust, less electronic failure | Sensitive to moisture and shock |

| Price | Generally lower cost | Higher cost due to electronics |

| Data Output | Manual recording | Some models with USB or Bluetooth |

| Applications | General inspection and machinery setup | Precision measurement and data logging |

Introduction to Dial Indicators and Digital Test Indicators

Dial indicators and digital test indicators are precision measuring instruments used to detect small variations in mechanical components. Dial indicators display measurements using a mechanical needle on a circular scale, while digital test indicators provide numerical readings via an electronic digital display. Digital test indicators often offer higher accuracy, easier readability, and additional features such as data output and zeroing functions compared to traditional dial indicators.

Key Differences Between Dial and Digital Test Indicators

Dial indicators use a mechanical needle to display measurements on a graduated scale, providing analog readings that are highly reliable without the need for batteries. Digital test indicators feature electronic displays that offer precise numerical readings, increased measurement resolution, and often include functions like data output or preset values. Your choice depends on the need for quick visual interpretation versus enhanced accuracy and digital data integration.

Accuracy and Precision Comparison

Dial indicators offer reliable accuracy for mechanical measurements, but digital test indicators provide enhanced precision through electronic readings with finer resolution. Your choice affects measurement consistency; digital indicators reduce human error by displaying values directly, while dial indicators rely on manual interpretation of the needle position. For high-precision applications, digital test indicators ensure superior repeatability and minimize parallax errors compared to traditional dial indicators.

Ease of Use and User Interface

Dial indicators feature a mechanical needle and graduated dial that provide a clear, tactile interface favored for straightforward measurements, but require manual zeroing and interpretation. Digital test indicators offer a digital display that simplifies reading through numeric output and often include features like zero setting, preset memory, and unit conversion, enhancing ease of use for quick, precise measurements. User interfaces on digital models reduce human error and improve efficiency, making them ideal for applications requiring fast data acquisition and minimal operator training.

Durability and Maintenance Requirements

Dial indicators typically offer greater durability due to their mechanical construction, making them highly resistant to drops and harsh environments. Digital test indicators, while offering enhanced precision and ease of reading, require more careful handling and regular battery replacements to maintain optimal performance. Your choice should consider the maintenance commitment and operational conditions to ensure long-term reliability.

Applications and Suitability for Tasks

Dial indicators are ideal for tasks requiring precise measurement of small linear distances and surface variations in machining, alignment, and inspection processes. Digital test indicators provide enhanced accuracy and ease of reading, making them suitable for complex measurements, data recording, and analysis in quality control environments. Your choice depends on whether you prioritize traditional tactile feedback and mechanical simplicity or advanced digital features and measurement versatility.

Cost Considerations and Value

Dial indicators generally offer a lower upfront cost compared to digital test indicators, making them a budget-friendly option for basic measurement tasks. Digital test indicators provide enhanced precision and ease of reading, which translates to greater long-term value in applications requiring high accuracy and repeatability. Choosing between the two depends on balancing initial expenditure with the need for advanced features and efficiency in measurement workflows.

Pros and Cons of Dial Indicators

Dial indicators offer precise mechanical readings with no reliance on batteries, making them highly reliable in environments where power sources are limited. They provide quick visual feedback through a clear, analog dial face, which some users find easier to interpret for fine measurements. However, their mechanical components can be more susceptible to wear and require regular calibration, and they may lack the advanced features and data integration capabilities found in digital test indicators.

Pros and Cons of Digital Test Indicators

Digital test indicators offer high precision and easy-to-read measurements, reducing human error compared to traditional dial indicators. You benefit from features like data storage, zero setting, and output capabilities for enhanced measurement analysis, though they typically require batteries and can be more expensive. However, their electronic components may be more sensitive to harsh environments, limiting durability in some industrial settings.

Choosing the Right Indicator for Your Needs

Dial indicators offer mechanical precision and durability ideal for environments where battery replacement or electronic failure is a concern, making them suitable for traditional machining tasks. Digital test indicators provide enhanced readability with digital displays, higher resolution, and data output capabilities, which are essential for quality control processes requiring precise measurements and easy integration with computer systems. Selecting the right indicator depends on factors such as required accuracy, measurement environment, data recording needs, and ease of use in your specific application.

Dial indicator vs digital test indicator Infographic

libmatt.com

libmatt.com