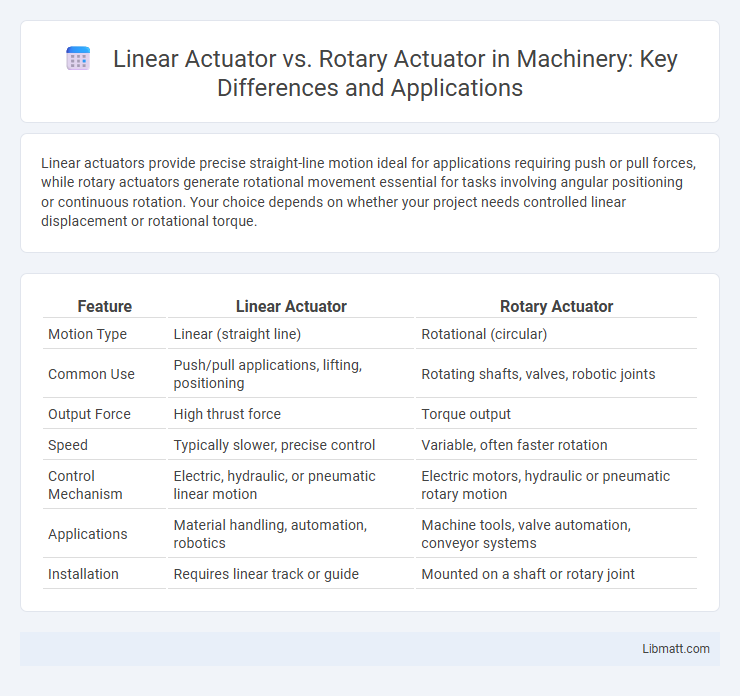

Linear actuators provide precise straight-line motion ideal for applications requiring push or pull forces, while rotary actuators generate rotational movement essential for tasks involving angular positioning or continuous rotation. Your choice depends on whether your project needs controlled linear displacement or rotational torque.

Table of Comparison

| Feature | Linear Actuator | Rotary Actuator |

|---|---|---|

| Motion Type | Linear (straight line) | Rotational (circular) |

| Common Use | Push/pull applications, lifting, positioning | Rotating shafts, valves, robotic joints |

| Output Force | High thrust force | Torque output |

| Speed | Typically slower, precise control | Variable, often faster rotation |

| Control Mechanism | Electric, hydraulic, or pneumatic linear motion | Electric motors, hydraulic or pneumatic rotary motion |

| Applications | Material handling, automation, robotics | Machine tools, valve automation, conveyor systems |

| Installation | Requires linear track or guide | Mounted on a shaft or rotary joint |

Introduction to Linear and Rotary Actuators

Linear actuators convert energy into straight-line motion, enabling precise control in applications like robotics and industrial machinery. Rotary actuators generate rotational movement, often used in systems requiring torque and angular displacement, such as valve control and automation equipment. Understanding the core mechanics of both actuator types helps optimize your choice for specific motion control needs.

Basic Working Principles

Linear actuators operate by converting energy, typically electrical, hydraulic, or pneumatic, into straight-line motion, often using a motor driving a screw or piston to extend or retract a shaft. Rotary actuators generate rotational motion by converting energy through mechanisms such as gears, cams, or motors to produce torque and angular displacement. Both actuator types serve distinct functions in automation, with the linear actuator providing linear displacement and the rotary actuator enabling rotational movement.

Key Differences Between Linear and Rotary Actuators

Linear actuators convert energy into straight-line motion, crucial for applications requiring precise positioning along a single axis, while rotary actuators generate rotational motion used in mechanisms needing angular displacement. Key differences include the type of movement, with linear actuators providing linear displacement measured in millimeters or inches, and rotary actuators offering rotational displacement measured in degrees or radians. Additionally, linear actuators often feature components such as lead screws or pneumatic cylinders, whereas rotary actuators utilize gears, motors, or hydraulic pistons to achieve torque and angular rotation.

Common Applications in Industry

Linear actuators are commonly used in industrial automation for precise positioning tasks such as conveyor systems, CNC machines, and robotic arms, where straight-line motion is essential. Rotary actuators excel in applications requiring rotational movement, including valve control, packaging machinery, and rotary indexing tables, offering reliable torque and angular displacement. Your choice depends on whether the process demands linear displacement or rotational force for optimal efficiency.

Advantages of Linear Actuators

Linear actuators provide precise, straight-line motion ideal for applications requiring accurate positioning and force control. They offer simplicity in design and are easier to integrate into systems requiring pushing, pulling, or lifting actions compared to rotary actuators. Their ability to deliver high force in a compact form factor makes them advantageous in manufacturing automation, robotics, and material handling.

Benefits of Rotary Actuators

Rotary actuators offer precise angular movement, making them ideal for applications requiring controlled rotation such as robotic arms and valve control systems. Their compact design and high torque output provide efficient performance in confined spaces, enhancing your machine's operational flexibility. Maintenance is often simpler due to fewer moving parts compared to linear actuators, reducing downtime and increasing system reliability.

Performance and Efficiency Comparison

Linear actuators provide precise, straight-line motion ideal for applications requiring accurate positioning and high force output, while rotary actuators excel in delivering continuous rotational movement with smooth torque control. Efficiency in linear actuators is often influenced by friction and load alignment, whereas rotary actuators typically benefit from lower energy consumption due to fewer mechanical losses during rotation. Your choice depends on specific performance needs, where linear actuators suit direct push-pull actions and rotary actuators are preferable for applications demanding efficient torque and rotational speed.

Selection Criteria: Choosing the Right Actuator

When selecting between a linear actuator and a rotary actuator, consider the specific motion requirements of your application, such as whether you need straight-line displacement or rotational movement. Evaluate factors like load capacity, speed, precision, and available space to ensure the actuator meets your operational demands. Your choice should align with the mechanical system design, control complexity, and energy efficiency needed for optimal performance.

Maintenance and Durability Considerations

Linear actuators typically require regular lubrication and alignment checks to maintain optimal performance, with wear primarily affecting the screw or rail components, while rotary actuators often demand less frequent maintenance due to their simpler rotational motion and sealed bearings. Durability of linear actuators can be compromised by exposure to contaminants and misalignment, whereas rotary actuators benefit from robust construction and sealed designs that enhance resistance to harsh environments. Selecting between the two should consider the operational context, as rotary actuators generally offer longer service life and lower maintenance costs in cyclical or repetitive applications.

Future Trends in Actuator Technology

Future trends in actuator technology emphasize increasing efficiency and precision in both linear and rotary actuators through advancements in smart materials and AI-driven control systems. Integration of IoT connectivity enables real-time monitoring and predictive maintenance, enhancing operational reliability across industries. Emerging developments such as piezoelectric actuators and electroactive polymers promise to revolutionize actuator design by reducing size and energy consumption while improving responsiveness.

Linear actuator vs rotary actuator Infographic

libmatt.com

libmatt.com