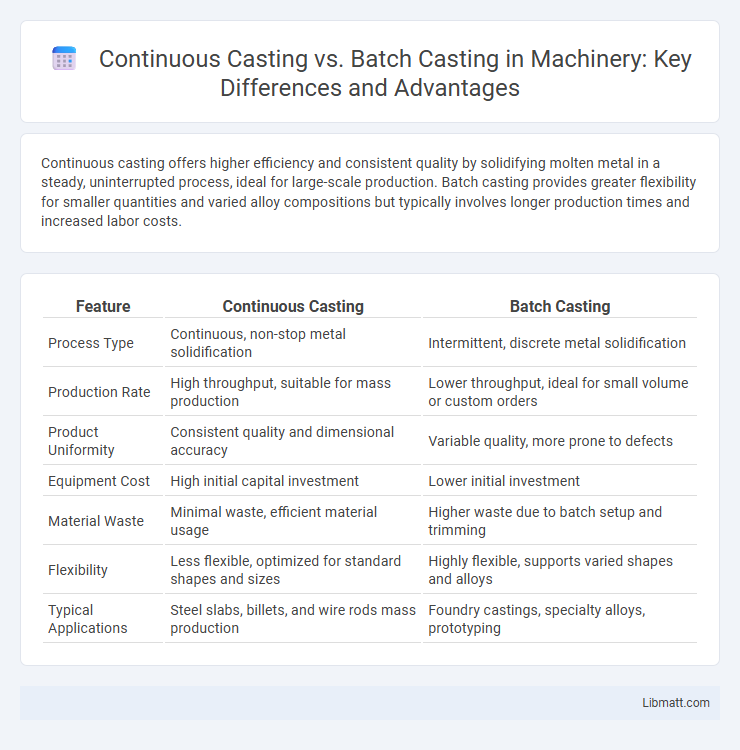

Continuous casting offers higher efficiency and consistent quality by solidifying molten metal in a steady, uninterrupted process, ideal for large-scale production. Batch casting provides greater flexibility for smaller quantities and varied alloy compositions but typically involves longer production times and increased labor costs.

Table of Comparison

| Feature | Continuous Casting | Batch Casting |

|---|---|---|

| Process Type | Continuous, non-stop metal solidification | Intermittent, discrete metal solidification |

| Production Rate | High throughput, suitable for mass production | Lower throughput, ideal for small volume or custom orders |

| Product Uniformity | Consistent quality and dimensional accuracy | Variable quality, more prone to defects |

| Equipment Cost | High initial capital investment | Lower initial investment |

| Material Waste | Minimal waste, efficient material usage | Higher waste due to batch setup and trimming |

| Flexibility | Less flexible, optimized for standard shapes and sizes | Highly flexible, supports varied shapes and alloys |

| Typical Applications | Steel slabs, billets, and wire rods mass production | Foundry castings, specialty alloys, prototyping |

Introduction to Continuous and Batch Casting

Continuous casting produces metal shapes by continuously solidifying molten metal into semi-finished billets, blooms, or slabs, enabling high-volume, consistent output and reduced waste. Batch casting involves pouring molten metal into molds in discrete batches, offering flexibility for varied shapes and smaller production runs but with longer cooling times and more manual handling. Your choice depends on production scale, material specifications, and desired efficiency in metal manufacturing.

Core Principles of Casting Methods

Continuous casting involves the uninterrupted solidification of molten metal as it flows through a cooled mold, producing a consistent and uniform product with minimal waste. Batch casting processes molten metal in discrete quantities, allowing for greater flexibility in alloy composition and smaller production runs. Your choice between these methods hinges on production volume, material properties, and desired product dimensions.

Process Workflow: Continuous Casting

Continuous casting involves the nonstop solidification of molten metal into semi-finished billets, blooms, or slabs. The process starts with molten metal poured into a water-cooled mold where solidification begins, followed by continuous withdrawal of the solidified strand at a controlled speed. This method streamlines production by eliminating intermediate steps like ingot casting and rolling, resulting in higher efficiency and improved metal quality.

Process Workflow: Batch Casting

Batch casting involves pouring molten metal into a mold cavity where it solidifies before removal, allowing precise control over individual castings. This process includes sequential steps of mold preparation, metal pouring, cooling, solidification, and demolding, optimized for producing complex shapes with high dimensional accuracy. Batch casting is ideal for low-volume production runs, providing flexibility in alloy composition and casting size adjustments.

Key Differences Between Continuous and Batch Casting

Continuous casting produces metal slabs or billets in a nonstop, automated process, enhancing efficiency and reducing material waste, while batch casting involves melting and pouring metal into molds in discrete quantities, allowing for greater flexibility in production. Continuous casting offers consistent quality and high-volume output suited for mass production, whereas batch casting provides customization and is ideal for smaller runs or varied alloy compositions. Your choice depends on production scale, product requirements, and cost considerations related to speed, precision, and resource utilization.

Advantages of Continuous Casting

Continuous casting offers significant advantages over batch casting, including higher production efficiency and reduced material waste due to its seamless, uninterrupted process. The method enhances product quality by providing uniform microstructure and dimensional accuracy, minimizing defects such as cold shuts and segregation. Continuous casting also lowers operational costs through energy savings and reduced labor requirements, making it ideal for large-scale steel and aluminum manufacturing.

Advantages of Batch Casting

Batch casting offers precise control over alloy composition and solidification conditions, resulting in higher-quality, defect-free ingots. It allows flexibility for producing varying sizes and shapes, making it ideal for specialized alloys and low-volume production runs. Enhanced metallurgical uniformity and ease of inspection during batch casting contribute to superior mechanical properties in the final product.

Limitations and Challenges of Each Method

Continuous casting faces limitations such as high initial equipment costs, the need for precise control of cooling rates, and difficulty in handling complex shapes or alloys with varying solidification characteristics. Batch casting challenges include lower efficiency due to intermittent operation, increased labor and energy consumption, and higher risk of defects like porosity or segregation caused by inconsistent cooling. Your choice between these methods should consider production volume, material properties, and product complexity to mitigate specific challenges effectively.

Industrial Applications and Use Cases

Continuous casting is predominantly used in large-scale steel production plants to efficiently produce high volumes of uniform billets, blooms, and slabs for automotive, construction, and shipbuilding industries. Batch casting finds applications in specialty alloys and small-batch production where precise control over composition and solidification is critical, such as aerospace components and custom tooling. The continuous process excels in mass production with lower operational costs, while batch casting supports flexibility and quality control for specialized materials.

Selecting the Right Casting Technique

Selecting the right casting technique depends on production volume, material type, and quality requirements. Continuous casting offers higher efficiency and consistent quality for large-scale steel manufacturing, while batch casting provides greater flexibility and is suitable for smaller production runs or diverse alloy compositions. Understanding these factors helps optimize cost, yield, and mechanical properties in metal fabrication.

Continuous casting vs batch casting Infographic

libmatt.com

libmatt.com