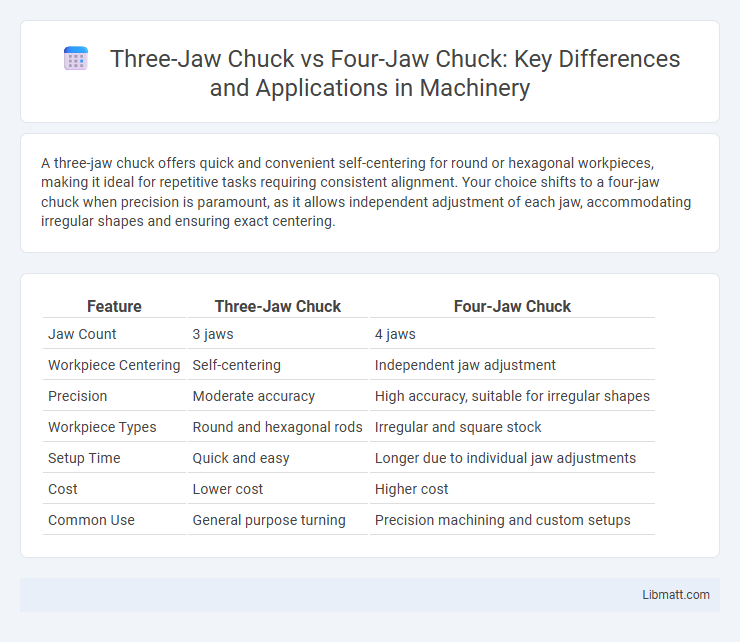

A three-jaw chuck offers quick and convenient self-centering for round or hexagonal workpieces, making it ideal for repetitive tasks requiring consistent alignment. Your choice shifts to a four-jaw chuck when precision is paramount, as it allows independent adjustment of each jaw, accommodating irregular shapes and ensuring exact centering.

Table of Comparison

| Feature | Three-Jaw Chuck | Four-Jaw Chuck |

|---|---|---|

| Jaw Count | 3 jaws | 4 jaws |

| Workpiece Centering | Self-centering | Independent jaw adjustment |

| Precision | Moderate accuracy | High accuracy, suitable for irregular shapes |

| Workpiece Types | Round and hexagonal rods | Irregular and square stock |

| Setup Time | Quick and easy | Longer due to individual jaw adjustments |

| Cost | Lower cost | Higher cost |

| Common Use | General purpose turning | Precision machining and custom setups |

Introduction to Lathe Chucks

Three-jaw chucks provide quick, automatic centering and are ideal for holding round or hexagonal workpieces, offering convenience and speed for repetitive tasks. Four-jaw chucks allow independent jaw adjustment, making them suitable for irregularly shaped or off-center materials, giving you greater precision in alignment. Choosing between these lathe chucks depends on the shape of your workpiece and the level of accuracy required for your machining project.

What Is a Three-Jaw Chuck?

A three-jaw chuck is a self-centering device commonly used in lathes and drills to hold cylindrical workpieces securely during machining. Its three jaws move simultaneously, ensuring quick and accurate centering of round or hexagonal objects, which enhances efficiency in repetitive tasks. Your choice of a three-jaw chuck is ideal for applications requiring fast setup with moderate precision.

What Is a Four-Jaw Chuck?

A four-jaw chuck is a type of lathe chuck featuring four independently adjustable jaws, allowing for precise centering and gripping of irregularly shaped or non-cylindrical workpieces. Unlike the three-jaw chuck, which automatically centers round objects, the four-jaw chuck provides greater versatility and accuracy in machining complex parts. It is commonly used in applications requiring high precision, such as metalworking and custom fabrication.

Key Differences Between Three-Jaw and Four-Jaw Chucks

Three-jaw chucks provide quick and automatic centering of round or hexagonal workpieces, making them ideal for repetitive tasks requiring uniformity. Four-jaw chucks allow independent adjustment of each jaw, offering greater versatility in holding irregular or off-center workpieces with precision. Understanding these key differences helps you select the right chuck to optimize accuracy and efficiency in your machining projects.

Advantages of Using a Three-Jaw Chuck

A three-jaw chuck offers quick and automatic centering, making it ideal for holding round or hexagonal workpieces with consistent accuracy. Its design simplifies setup time, allowing You to efficiently secure materials for turning or milling operations without manual adjustments. The uniform grip from three jaws enhances stability and reduces vibrations during machining processes, improving overall precision and surface finish.

Benefits of Four-Jaw Chucks

Four-jaw chucks provide enhanced precision by allowing independent adjustment of each jaw, enabling the secure clamping of irregularly shaped or non-cylindrical workpieces. These chucks offer improved versatility and accuracy in machining tasks that demand exact centering and customization. Their ability to compensate for workpiece inconsistencies results in higher quality finishes and reduced setup time compared to three-jaw chucks.

Common Applications for Each Chuck Type

Three-jaw chucks are commonly used in applications requiring quick and uniform clamping of round or hexagonal workpieces, such as metal turning and drilling, where efficiency and repeatability are crucial. Four-jaw chucks excel in holding irregularly shaped or off-center objects, making them ideal for precision machining tasks like square or rectangular stock turning and custom shaping. Your choice depends on whether you prioritize speed and consistency with a three-jaw or versatility and precise alignment with a four-jaw chuck.

Precision and Accuracy Comparison

A four-jaw chuck offers superior precision and accuracy by allowing independent jaw adjustment, enabling the workpiece to be centered meticulously even if irregularly shaped. In contrast, a three-jaw chuck self-centers automatically, which provides faster setup but less fine-tuned accuracy, making it better suited for round materials. For tasks demanding exact alignment and minimal runout, the adjustable nature of a four-jaw chuck ensures higher machining precision.

Maintenance and Setup Requirements

Three-jaw chucks require less maintenance and quicker setup due to their self-centering mechanism, making them ideal for repetitive tasks with round or hexagonal workpieces. Four-jaw chucks demand more frequent adjustments and careful alignment since each jaw operates independently, providing superior precision for irregular or square materials. Your choice impacts setup time and routine upkeep, with three-jaw chucks favoring efficiency and four-jaw chucks emphasizing versatility and accuracy.

Choosing the Right Chuck for Your Lathe

Choosing the right chuck for your lathe depends on the type of workpiece and required precision; three-jaw chucks offer quick, self-centering clamping ideal for round or hexagonal stock, while four-jaw chucks provide independent jaw adjustment for irregular or square shapes, enabling higher accuracy. Three-jaw chucks are preferred for repetitive tasks due to faster setup times, whereas four-jaw chucks excel in custom or complex turning projects requiring precise alignment. Assessing the material, shape, and tolerance requirements ensures optimal performance and machining efficiency with the selected chuck type.

Three-jaw chuck vs four-jaw chuck Infographic

libmatt.com

libmatt.com