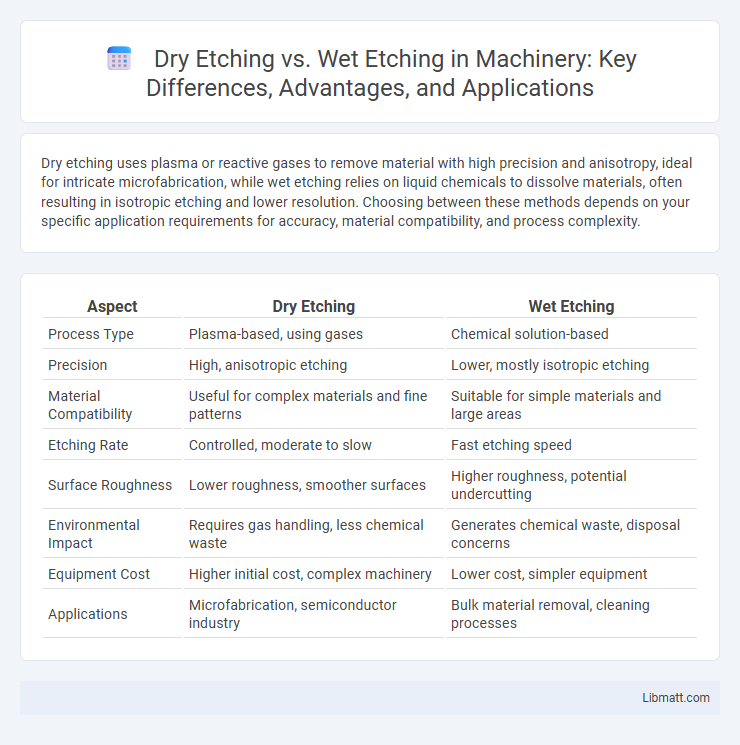

Dry etching uses plasma or reactive gases to remove material with high precision and anisotropy, ideal for intricate microfabrication, while wet etching relies on liquid chemicals to dissolve materials, often resulting in isotropic etching and lower resolution. Choosing between these methods depends on your specific application requirements for accuracy, material compatibility, and process complexity.

Table of Comparison

| Aspect | Dry Etching | Wet Etching |

|---|---|---|

| Process Type | Plasma-based, using gases | Chemical solution-based |

| Precision | High, anisotropic etching | Lower, mostly isotropic etching |

| Material Compatibility | Useful for complex materials and fine patterns | Suitable for simple materials and large areas |

| Etching Rate | Controlled, moderate to slow | Fast etching speed |

| Surface Roughness | Lower roughness, smoother surfaces | Higher roughness, potential undercutting |

| Environmental Impact | Requires gas handling, less chemical waste | Generates chemical waste, disposal concerns |

| Equipment Cost | Higher initial cost, complex machinery | Lower cost, simpler equipment |

| Applications | Microfabrication, semiconductor industry | Bulk material removal, cleaning processes |

Introduction to Etching Processes

Dry etching utilizes plasma or reactive gases to precisely remove material from a substrate, enabling high-resolution patterning essential for semiconductor manufacturing. Wet etching involves chemical solutions that dissolve specific materials, offering simplicity and cost-effectiveness but with less control over feature dimensions. Your choice between dry and wet etching depends on the desired precision, material compatibility, and process requirements in microfabrication.

Overview of Dry Etching

Dry etching uses plasma or reactive gases to precisely remove material from a substrate, offering high anisotropy and fine pattern control compared to wet etching. This technique is essential in semiconductor manufacturing for creating intricate microelectronic structures with minimal undercutting. You benefit from enhanced etch uniformity and compatibility with advanced lithography in dry etching processes.

Overview of Wet Etching

Wet etching is a material removal process that uses liquid chemical solutions to selectively dissolve specific areas of a substrate, commonly silicon, metals, or oxides. This technique offers isotropic etching profiles, making it suitable for applications requiring uniform material removal, but it can lead to undercutting beneath the mask layers. Precise control of factors such as etchant concentration, temperature, and duration is essential to achieve desired etch rates and surface quality in semiconductor fabrication and microelectromechanical systems (MEMS).

Key Differences Between Dry and Wet Etching

Dry etching utilizes plasma or reactive gases to precisely remove material from substrates, offering greater anisotropy and better control in microfabrication. Wet etching involves chemical solutions that selectively dissolve material, typically resulting in isotropic etching suitable for less complex patterns. Key differences include etch profile accuracy, process contamination risk, and suitability for high-resolution applications, with dry etching preferred for fine-feature patterning and wet etching favored for faster, bulk material removal.

Advantages of Dry Etching

Dry etching offers superior precision and anisotropy compared to wet etching, enabling the creation of highly detailed and vertical sidewalls essential for advanced semiconductor devices. It provides better control over etch depth and uniformity, reducing undercutting and improving pattern fidelity on complex substrates. Additionally, dry etching is compatible with cleanroom environments by minimizing chemical waste and contamination risks, enhancing overall process reliability.

Advantages of Wet Etching

Wet etching offers precise material removal with excellent isotropy, making it ideal for uniform etching of complex shapes. It is cost-effective, utilizing simple chemical solutions that require minimal equipment, which reduces process expenses. Your microfabrication processes can benefit from its high throughput and scalability, suitable for both small and large-scale applications.

Applications in Semiconductor Manufacturing

Dry etching offers precise pattern transfer and anisotropic profiles essential for advanced semiconductor devices, making it ideal for creating high-resolution microchips and intricate circuit patterns. Wet etching is favored for bulk material removal or less complex applications due to its simplicity and cost-effectiveness, commonly used in cleaning and thinning silicon wafers. Your semiconductor manufacturing process benefits from selecting dry etching when precision and feature control are critical, while wet etching suits tasks requiring larger material removal with minimal equipment complexity.

Environmental and Safety Considerations

Dry etching typically involves the use of reactive gases and plasma, which require specialized ventilation systems and pose risks related to toxic gas exposure and plasma radiation, demanding stringent safety protocols to protect workers. Wet etching uses liquid chemicals that may be hazardous, corrosive, or toxic, necessitating careful handling, disposal, and proper containment to prevent environmental contamination and chemical burns. Understanding these environmental and safety considerations helps you implement effective risk management strategies in semiconductor manufacturing processes.

Cost and Efficiency Comparison

Dry etching offers higher precision and faster processing times, making it more efficient despite its higher initial equipment costs. Wet etching is generally less expensive due to simpler tools and lower material expenses but often results in slower etch rates and less control over feature dimensions. In semiconductor manufacturing, dry etching's superior anisotropy and repeatability justify its premium cost for complex, high-volume production.

Choosing the Right Etching Method

Choosing the right etching method depends on the precision, material compatibility, and desired etch profile for your project. Dry etching offers superior control and anisotropy, making it ideal for intricate semiconductor patterns, while wet etching is cost-effective and efficient for materials that tolerate isotropic etching and less complex geometries. Understanding these factors ensures your selection optimally balances performance and manufacturing efficiency.

Dry etching vs wet etching Infographic

libmatt.com

libmatt.com