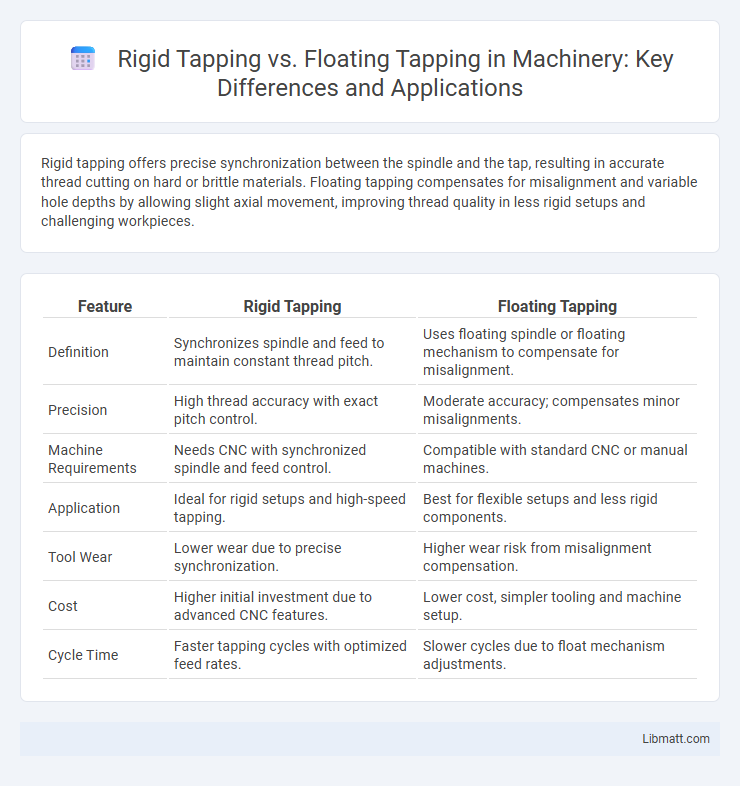

Rigid tapping offers precise synchronization between the spindle and the tap, resulting in accurate thread cutting on hard or brittle materials. Floating tapping compensates for misalignment and variable hole depths by allowing slight axial movement, improving thread quality in less rigid setups and challenging workpieces.

Table of Comparison

| Feature | Rigid Tapping | Floating Tapping |

|---|---|---|

| Definition | Synchronizes spindle and feed to maintain constant thread pitch. | Uses floating spindle or floating mechanism to compensate for misalignment. |

| Precision | High thread accuracy with exact pitch control. | Moderate accuracy; compensates minor misalignments. |

| Machine Requirements | Needs CNC with synchronized spindle and feed control. | Compatible with standard CNC or manual machines. |

| Application | Ideal for rigid setups and high-speed tapping. | Best for flexible setups and less rigid components. |

| Tool Wear | Lower wear due to precise synchronization. | Higher wear risk from misalignment compensation. |

| Cost | Higher initial investment due to advanced CNC features. | Lower cost, simpler tooling and machine setup. |

| Cycle Time | Faster tapping cycles with optimized feed rates. | Slower cycles due to float mechanism adjustments. |

Introduction to Rigid and Floating Tapping

Rigid tapping ensures precise synchronization between the spindle rotation and feed rate using a rigid coupling, ideal for machining hardened materials and threads requiring high accuracy. Floating tapping employs a floating tap holder allowing axial movement to compensate for alignment errors, reducing tool breakage in machines lacking synchronized feed. Both methods optimize thread quality by addressing different machine capabilities and application requirements in CNC machining.

What is Rigid Tapping?

Rigid tapping is a precise machining process where the tap is synchronized with the spindle's rotation using CNC controls, ensuring accurate thread cutting without axial load on the spindle. This method improves thread quality by maintaining consistent feed rates and minimizing tool wear. It is ideal for high-speed tapping applications requiring tight tolerance and repeatability.

What is Floating Tapping?

Floating tapping is a machining technique where the tapping tool is allowed a slight axial movement to compensate for minor misalignments between the tap and the hole. This method reduces the risk of tap breakage and improves thread quality, especially when rigid machine spindle alignment is challenging. You can achieve better tapping accuracy and tool longevity in setups with slight machine or workpiece variances using floating tapping.

Key Differences Between Rigid and Floating Tapping

Rigid tapping offers precise synchronization between spindle rotation and feed rate, ensuring consistent thread quality and is ideal for CNC machines with rigid tapping capability. Floating tapping compensates for small misalignments between the tap and the hole, reducing tap breakage and is beneficial when machine rigidity or alignment is less accurate. The key differences include rigidity of the system, control method, and tolerance for misalignment, which directly impact tapping accuracy and tool life.

Advantages of Rigid Tapping

Rigid tapping offers precise synchronization between the spindle and the feed rate, resulting in highly accurate thread profiles and improved surface finishes. This method reduces tool wear and minimizes the risk of tap breakage by maintaining consistent torque and eliminating axial thrust fluctuations. Your machining efficiency benefits from increased cycle times and reliable thread quality, especially in CNC applications.

Advantages of Floating Tapping

Floating tapping offers enhanced flexibility by accommodating minor misalignments between the tap and hole, reducing the risk of tap breakage and improving tool life. This method allows your machine to compensate for spindle runout and workpiece irregularities, leading to higher thread quality and consistent tapping results. The ability to adjust dynamically to cutting conditions makes floating tapping ideal for delicate materials or complex geometries where precision is critical.

Applications Best Suited for Rigid Tapping

Rigid tapping is best suited for high-precision applications requiring synchronized spindle and feed motions, such as aerospace component manufacturing and automotive engine parts. Your CNC machines benefit from this method during tasks that demand consistent thread quality and repeatability, especially in hard materials where tool rigidity enhances performance. Industries involving metalworking, mold making, and electronics assembly often prefer rigid tapping for its ability to reduce cycle times and improve thread accuracy.

Applications Best Suited for Floating Tapping

Floating tapping is best suited for applications involving thin-walled or flexible materials where alignment issues between the spindle and workpiece may occur. It excels in machining parts with delicate threads or when working with materials that are prone to deformation, such as aluminum or plastic. This method minimizes tool breakage and improves thread quality in setups lacking rigid spindle support.

Factors to Consider When Choosing Tapping Methods

Choosing between rigid tapping and floating tapping depends on machine tool rigidity, spindle speed stability, and workpiece material hardness. Rigid tapping ensures precise thread depth and pitch accuracy on machines with synchronized spindle and feed drives, suitable for high-volume production of harder materials. Floating tapping accommodates slight misalignments and is preferred for delicate workpieces or setups with less rigid machinery to prevent tap breakage.

Conclusion: Selecting the Right Tapping Method

Selecting the right tapping method depends on machining stability and tool control, with rigid tapping offering precise synchronization between the spindle and tap for high-accuracy threading in CNC machines. Floating tapping provides flexibility by compensating for misalignment and material inconsistencies, reducing the risk of tap breakage in less rigid setups or uneven workpieces. Evaluating factors such as machine rigidity, spindle drive capability, and thread quality requirements ensures optimal tapping performance and tool life.

Rigid tapping vs floating tapping Infographic

libmatt.com

libmatt.com