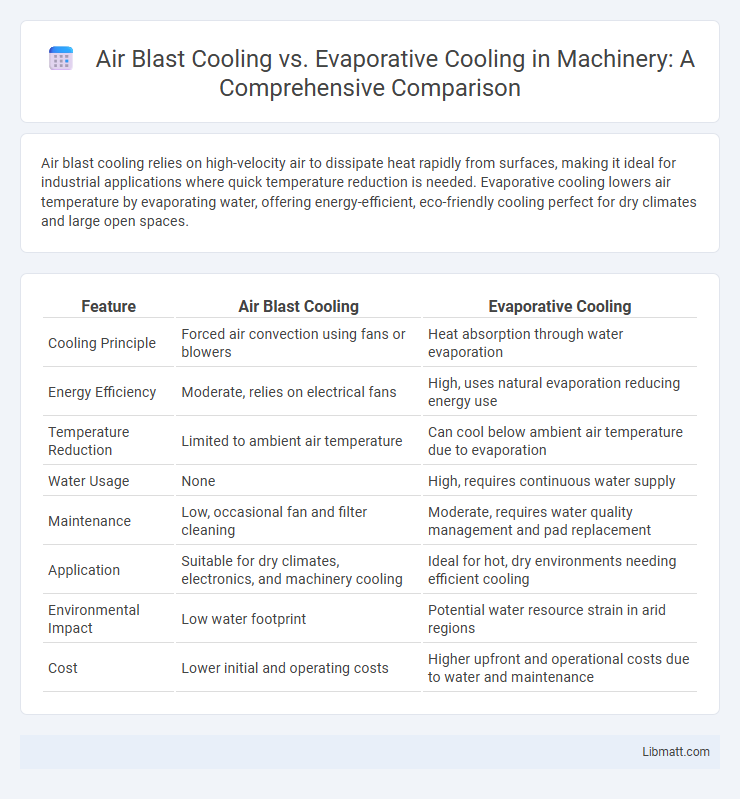

Air blast cooling relies on high-velocity air to dissipate heat rapidly from surfaces, making it ideal for industrial applications where quick temperature reduction is needed. Evaporative cooling lowers air temperature by evaporating water, offering energy-efficient, eco-friendly cooling perfect for dry climates and large open spaces.

Table of Comparison

| Feature | Air Blast Cooling | Evaporative Cooling |

|---|---|---|

| Cooling Principle | Forced air convection using fans or blowers | Heat absorption through water evaporation |

| Energy Efficiency | Moderate, relies on electrical fans | High, uses natural evaporation reducing energy use |

| Temperature Reduction | Limited to ambient air temperature | Can cool below ambient air temperature due to evaporation |

| Water Usage | None | High, requires continuous water supply |

| Maintenance | Low, occasional fan and filter cleaning | Moderate, requires water quality management and pad replacement |

| Application | Suitable for dry climates, electronics, and machinery cooling | Ideal for hot, dry environments needing efficient cooling |

| Environmental Impact | Low water footprint | Potential water resource strain in arid regions |

| Cost | Lower initial and operating costs | Higher upfront and operational costs due to water and maintenance |

Introduction to Air Blast and Evaporative Cooling

Air blast cooling utilizes high-velocity air to rapidly lower temperature by increasing convective heat transfer, making it effective for cooling electrical transformers and industrial equipment. Evaporative cooling leverages the phase change of water evaporation to absorb heat, providing an energy-efficient cooling method ideal for HVAC systems and green building applications. Both techniques enhance thermal management but differ significantly in mechanism, energy consumption, and suitability for various environments.

How Air Blast Cooling Works

Air blast cooling works by directing high-velocity fans or blowers to force ambient air over hot surfaces or materials, rapidly dissipating heat through convection. This method relies on the temperature difference between the air and the heated object to transfer thermal energy away, enabling efficient cooling without the need for water consumption or complex systems. Your choice of air blast cooling is ideal for applications requiring fast, dry cooling in environments where water conservation or humidity control is important.

How Evaporative Cooling Works

Evaporative cooling operates by passing warm air through water-saturated pads, where the heat causes water to evaporate and cool the air. This process reduces the air temperature by increasing humidity, making it energy-efficient and suitable for dry climates. Air blast cooling, in contrast, relies on high-velocity air to lower temperatures without altering humidity levels.

Key Differences Between Air Blast and Evaporative Cooling

Air blast cooling uses high-velocity air to rapidly lower temperatures by direct heat transfer, making it ideal for industrial applications requiring quick cooling. Evaporative cooling relies on water evaporation to absorb heat, resulting in energy-efficient and environmentally friendly temperature reduction, especially effective in dry climates. Your choice between these methods depends on factors like ambient humidity, cooling speed, and energy consumption priorities.

Energy Efficiency Comparison

Air blast cooling consumes more energy due to the reliance on high-powered fans to rapidly circulate ambient air over equipment or products. Evaporative cooling offers superior energy efficiency by utilizing the natural process of water evaporation to lower temperatures with minimal electrical input. Your choice can significantly impact operational costs, with evaporative systems often providing more sustainable cooling solutions in dry climates.

Installation and Maintenance Requirements

Air blast cooling requires straightforward installation with fewer components, making it suitable for areas where rapid deployment is necessary, and maintenance involves routine checks of fans and filters to ensure optimal airflow. Evaporative cooling demands more complex installation, including water supply and drainage systems, and regular maintenance to prevent mineral buildup and microbial growth in the water pads and reservoirs. Your choice depends on balancing the ease of installation and ongoing maintenance efforts against cooling efficiency and environmental conditions.

Climate Suitability for Each Cooling Method

Air blast cooling performs effectively in dry, arid climates where low humidity allows rapid heat dissipation through forced airflow, making it ideal for desert and semi-arid regions. Evaporative cooling thrives in hot, dry environments with low humidity, such as southwestern United States, by leveraging water evaporation to reduce air temperature efficiently. Your choice depends on local climate; air blast cooling suits consistently dry areas, while evaporative cooling offers greater benefits where occasional ambient moisture is present but humidity remains low.

Environmental Impact and Sustainability

Air blast cooling consumes significant energy due to the operation of large fans, resulting in higher carbon emissions compared to evaporative cooling, which relies primarily on natural water evaporation and uses less electricity. Evaporative cooling reduces environmental impact by lowering greenhouse gas emissions and conserving energy, but it depends on water availability, which can be a concern in drought-prone regions. Your sustainable choice depends on balancing energy consumption with water use, prioritizing local environmental conditions and resource availability.

Cost Analysis: Initial and Long-term Expenses

Air blast cooling typically involves lower initial costs due to simpler equipment and installation requirements, but it can incur higher long-term energy expenses because of continuous fan operation. Evaporative cooling systems often require higher upfront investment for water distribution components and maintenance but benefit from lower operational costs, leveraging natural evaporation to reduce energy consumption. Evaluating total cost of ownership reveals evaporative cooling as more cost-effective in dry climates with abundant water, whereas air blast cooling suits environments prioritizing minimal initial expenditure.

Choosing the Right Cooling System for Your Application

Selecting the right cooling system depends on your application's specific requirements, including environmental conditions and energy efficiency goals. Air blast cooling is ideal for rapid, localized cooling with low humidity impact, while evaporative cooling excels in dry climates by reducing temperature through water evaporation and energy savings. Assessing factors like climate, operational costs, and cooling capacity ensures the most effective system for your needs.

Air blast cooling vs evaporative cooling Infographic

libmatt.com

libmatt.com