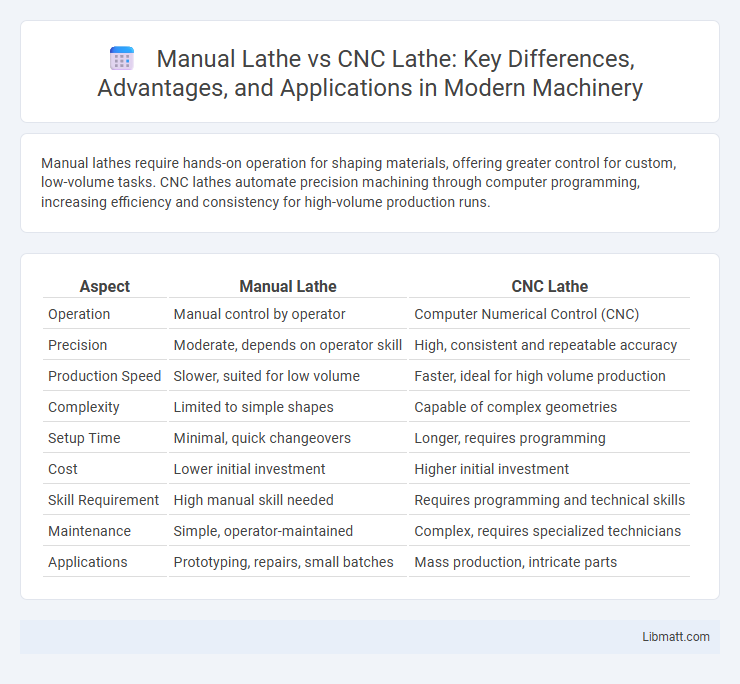

Manual lathes require hands-on operation for shaping materials, offering greater control for custom, low-volume tasks. CNC lathes automate precision machining through computer programming, increasing efficiency and consistency for high-volume production runs.

Table of Comparison

| Aspect | Manual Lathe | CNC Lathe |

|---|---|---|

| Operation | Manual control by operator | Computer Numerical Control (CNC) |

| Precision | Moderate, depends on operator skill | High, consistent and repeatable accuracy |

| Production Speed | Slower, suited for low volume | Faster, ideal for high volume production |

| Complexity | Limited to simple shapes | Capable of complex geometries |

| Setup Time | Minimal, quick changeovers | Longer, requires programming |

| Cost | Lower initial investment | Higher initial investment |

| Skill Requirement | High manual skill needed | Requires programming and technical skills |

| Maintenance | Simple, operator-maintained | Complex, requires specialized technicians |

| Applications | Prototyping, repairs, small batches | Mass production, intricate parts |

Introduction to Manual and CNC Lathes

Manual lathes require direct operator control for cutting and shaping materials, making them ideal for simple, one-off tasks or low-volume production. CNC lathes operate via computer numerical control, enabling precise and automated machining of complex parts with high repeatability and efficiency. Understanding the functions of both manual and CNC lathes helps you choose the right tool for your specific manufacturing needs.

Key Differences Between Manual and CNC Lathes

Manual lathes require direct operator control for every movement, offering tactile feedback and flexibility in custom, small-batch tasks, whereas CNC lathes use computer programming to automate precise and repetitive machining operations, ensuring higher accuracy and efficiency. CNC machines excel in complex geometries and mass production due to automated tool changes and consistent operation, while manual lathes are more suited for hands-on adjustments and simpler shapes. Understanding these key differences helps you choose the right lathe for your machining needs based on precision, volume, and workflow complexity.

Precision and Accuracy Comparison

CNC lathes deliver significantly higher precision and accuracy than manual lathes due to computer-controlled movements that minimize human error. Tolerances on CNC machines often reach micrometer levels, enabling complex and consistent part production. Manual lathes depend heavily on operator skill, resulting in variable accuracy and less repeatability in high-precision applications.

Speed and Efficiency in Machining

CNC lathes offer significantly higher speed and efficiency in machining compared to manual lathes due to automated, computer-controlled operations that reduce cycle times and increase precision. Manual lathes rely on operator skill and slower manual adjustments, which limits throughput and consistency in production. Advanced CNC systems optimize tool paths and enable continuous multitasking, enhancing productivity in high-volume manufacturing settings.

Skill Level and Operator Requirements

Manual lathes require a high skill level and hands-on expertise since operators must control all movements and adjustments manually, demanding precision and experience. CNC lathes automate machining processes through computer programming, reducing the need for extensive manual skills while requiring knowledge in software operation and programming. Your choice depends on whether you prioritize traditional craftsmanship or automated precision with streamlined operator training.

Initial Investment and Operating Costs

Manual lathes require a lower initial investment, making them suitable for small workshops or individual craftsmen with limited budgets. CNC lathes involve higher upfront costs due to advanced technology and software but offer reduced operating expenses through automation, increased precision, and less material waste. Your choice affects long-term profitability, as CNC lathes typically lower labor costs and improve production efficiency despite the greater initial expenditure.

Flexibility and Versatility of Operations

Manual lathes offer greater flexibility for custom or one-off projects, allowing you to make quick adjustments and changes on the fly without programming. CNC lathes excel in versatility by automating complex and repetitive operations with high precision, supporting a wide range of machining tasks through programmable toolpaths. Your choice depends on whether you prioritize hands-on control or efficient, consistent production across diverse applications.

Maintenance and Longevity Considerations

Manual lathes require regular mechanical adjustments and lubrication to maintain precision, with wear primarily affecting gears and bearings, resulting in predictable maintenance schedules. CNC lathes demand software updates, sensor calibrations, and complex electronic diagnostics, with longevity often enhanced by automated error detection and cooler operating conditions. Both types benefit from consistent upkeep, but CNC lathes typically offer extended service life due to advanced monitoring and precision engineering.

Applications Best Suited for Each Lathe

Manual lathes excel in custom, low-volume, or prototype machining where operator skill and flexibility are crucial, often used in small workshops and for maintenance tasks. CNC lathes are best suited for high-precision, high-volume production runs requiring consistent repeatability and complex geometries, commonly employed in automotive, aerospace, and electronics manufacturing. The choice depends on workpiece complexity, production scale, and required accuracy.

Making the Right Choice: Manual vs CNC Lathe

Choosing between a manual lathe and a CNC lathe depends on your production needs, precision requirements, and budget constraints. Manual lathes offer greater control for small-scale, custom tasks, while CNC lathes excel in high-volume manufacturing with repeatable accuracy and automation. Assessing your project's complexity and desired output will help you determine the most efficient investment for your machining operations.

Manual lathe vs CNC lathe Infographic

libmatt.com

libmatt.com