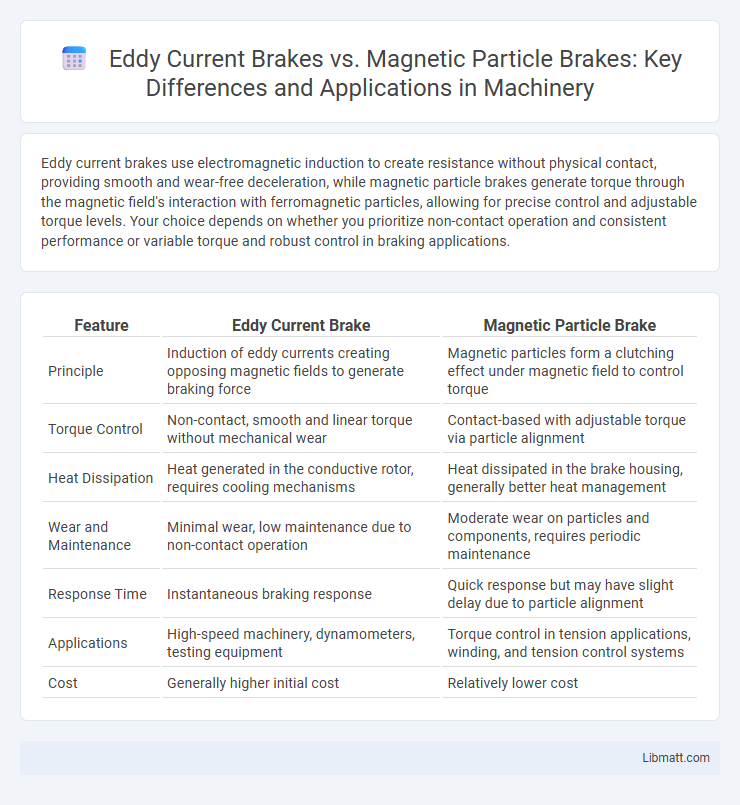

Eddy current brakes use electromagnetic induction to create resistance without physical contact, providing smooth and wear-free deceleration, while magnetic particle brakes generate torque through the magnetic field's interaction with ferromagnetic particles, allowing for precise control and adjustable torque levels. Your choice depends on whether you prioritize non-contact operation and consistent performance or variable torque and robust control in braking applications.

Table of Comparison

| Feature | Eddy Current Brake | Magnetic Particle Brake |

|---|---|---|

| Principle | Induction of eddy currents creating opposing magnetic fields to generate braking force | Magnetic particles form a clutching effect under magnetic field to control torque |

| Torque Control | Non-contact, smooth and linear torque without mechanical wear | Contact-based with adjustable torque via particle alignment |

| Heat Dissipation | Heat generated in the conductive rotor, requires cooling mechanisms | Heat dissipated in the brake housing, generally better heat management |

| Wear and Maintenance | Minimal wear, low maintenance due to non-contact operation | Moderate wear on particles and components, requires periodic maintenance |

| Response Time | Instantaneous braking response | Quick response but may have slight delay due to particle alignment |

| Applications | High-speed machinery, dynamometers, testing equipment | Torque control in tension applications, winding, and tension control systems |

| Cost | Generally higher initial cost | Relatively lower cost |

Introduction to Non-Contact Braking Technologies

Non-contact braking technologies such as Eddy current brakes and magnetic particle brakes offer frictionless control by utilizing electromagnetic forces to generate resistance without physical contact. Eddy current brakes operate by inducing currents in conductive materials that create opposing magnetic fields, providing smooth deceleration with minimal wear. Magnetic particle brakes use magnetized ferrous particles suspended in a fluid to produce controllable torque, enabling precise torque control and rapid response in industrial applications.

What is an Eddy Current Brake?

An Eddy Current Brake is a non-contact braking system that uses electromagnetic induction to generate opposing forces, slowing down or stopping a moving object without physical wear. This brake operates by passing an electric current through a conductor moving within a magnetic field, creating eddy currents that produce a magnetic force opposing the motion. Its advantages include smooth, quiet operation and minimal maintenance compared to mechanical brakes, making it suitable for applications in trains, roller coasters, and industrial machines.

How Magnetic Particle Brakes Work

Magnetic particle brakes operate by applying a magnetic field to magnetize ferrous particles suspended in a disc or drum, creating variable resistance between the input and output components. When current flows through the coil, the magnetic particles align and solidify, controlling torque transfer and producing precise and adjustable braking force. This electromagnetic mechanism allows for smooth, controllable braking suitable for torque testing, tension control, and industrial applications.

Core Design Differences

Eddy current brakes utilize a solid conductive disc or drum passing through a magnetic field to generate resistance without physical contact, relying on the principle of electromagnetic induction. Magnetic particle brakes feature a magnetic particle-filled cavity between the input and output components, where magnetic fields align the particles to create adjustable torque through controlled friction. Your choice depends on whether you need contactless smooth braking with minimal wear (eddy current) or variable torque control with higher holding capacity (magnetic particle).

Performance Comparison in Industrial Applications

Eddy current brakes offer fast, contactless deceleration with minimal wear, making them ideal for high-speed industrial applications requiring smooth, low-maintenance operation. Magnetic particle brakes provide precise torque control and consistent holding force, suitable for tasks needing adjustable braking and reliable performance under high load conditions. Industrial performance optimization often balances the eddy current brake's efficiency at varying speeds against the magnetic particle brake's superior control and torque accuracy.

Efficiency and Response Time Analysis

Eddy current brakes exhibit high efficiency in dissipating kinetic energy without physical contact, resulting in minimal wear and rapid response times suitable for dynamic braking applications. Magnetic particle brakes provide precise torque control with moderate efficiency but generally slower response times due to the magnetic field build-up required for engagement. Your selection depends on whether immediate braking response or controlled torque modulation is prioritized in the application.

Maintenance and Durability Considerations

Eddy current brakes require minimal maintenance due to their contactless operation, which reduces wear and tear significantly, resulting in longer durability under continuous use. Magnetic particle brakes involve frictional contact, necessitating periodic inspection and replacement of particles to maintain performance and prevent abrasive wear. Your choice depends on the application's tolerance for maintenance intervals and the desired lifespan of the braking system.

Cost Implications and Investment Value

Eddy current brakes generally have lower upfront costs due to their simpler design and lack of wear parts, making them a cost-effective option for applications requiring consistent braking without physical contact. Magnetic particle brakes, while typically more expensive initially, offer higher torque capacity and precise control, providing better long-term investment value for heavy-duty or precision-demanding uses. Your choice should consider not only the initial expenditure but also maintenance costs and application-specific performance needs to maximize return on investment.

Key Application Scenarios: When to Use Each Brake

Eddy current brakes are ideal for high-speed applications requiring smooth, contactless deceleration, such as in amusement park rides, train wind tunnels, and industrial machinery testing. Magnetic particle brakes excel in precise torque control and are preferred in tension control systems, dynamometers, and industrial automation where adjustable braking force and quick response are crucial. You should choose an eddy current brake for maintenance-free, wear-free operation and a magnetic particle brake when you need fine-tuned torque control and versatility in load management.

Choosing the Right Brake: Decision Factors

Choosing the right brake between Eddy current and magnetic particle types depends on your application's speed control accuracy and heat dissipation needs. Eddy current brakes excel in contactless, low-maintenance operation with smooth torque control, making them ideal for high-speed, continuous processes. Magnetic particle brakes offer precise torque adjustment and quick response, suited for lower-speed, high-torque tasks requiring controlled braking performance.

Eddy current brake vs magnetic particle brake Infographic

libmatt.com

libmatt.com