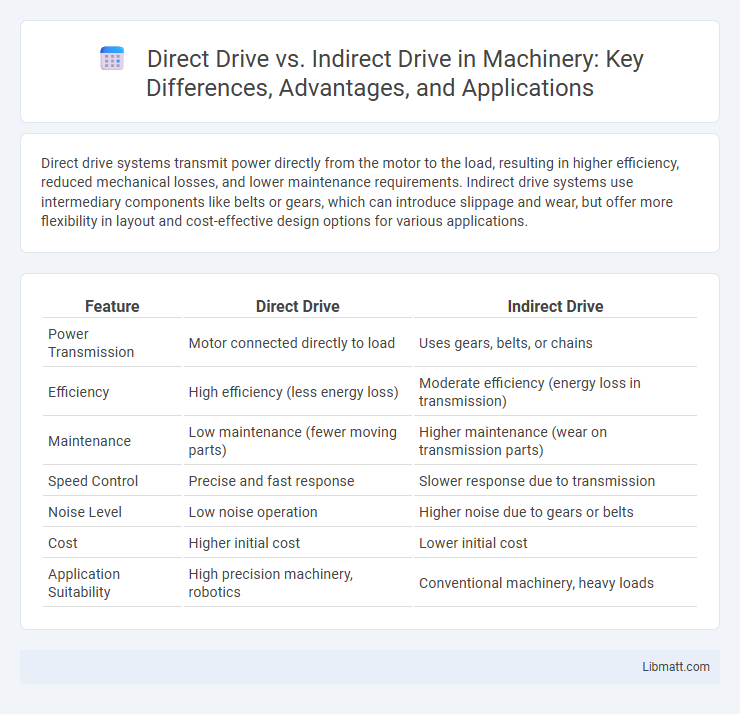

Direct drive systems transmit power directly from the motor to the load, resulting in higher efficiency, reduced mechanical losses, and lower maintenance requirements. Indirect drive systems use intermediary components like belts or gears, which can introduce slippage and wear, but offer more flexibility in layout and cost-effective design options for various applications.

Table of Comparison

| Feature | Direct Drive | Indirect Drive |

|---|---|---|

| Power Transmission | Motor connected directly to load | Uses gears, belts, or chains |

| Efficiency | High efficiency (less energy loss) | Moderate efficiency (energy loss in transmission) |

| Maintenance | Low maintenance (fewer moving parts) | Higher maintenance (wear on transmission parts) |

| Speed Control | Precise and fast response | Slower response due to transmission |

| Noise Level | Low noise operation | Higher noise due to gears or belts |

| Cost | Higher initial cost | Lower initial cost |

| Application Suitability | High precision machinery, robotics | Conventional machinery, heavy loads |

Introduction to Direct Drive and Indirect Drive

Direct drive systems transmit power directly from the motor to the load, eliminating intermediate components like belts or gears, which enhances efficiency and reduces maintenance requirements. Indirect drive systems use intermediary elements such as pulleys, chains, or gears to transfer motion, providing flexibility in speed and torque adjustments but often at the cost of increased wear and energy loss. Your choice between direct drive and indirect drive depends on factors like precision, durability, and application-specific performance needs.

How Direct Drive Systems Work

Direct drive systems transmit power directly from the motor to the driven component without intermediary parts like belts or gears, reducing energy loss and mechanical complexity. This design enhances efficiency, responsiveness, and durability by minimizing friction and maintenance requirements. You benefit from smoother operation and improved precision in applications such as electric vehicles, industrial machinery, and exercise equipment.

Understanding Indirect Drive Mechanisms

Indirect drive mechanisms use gears, belts, or chains to transfer power between the motor and the driven component, allowing for torque multiplication and speed adjustment. These systems reduce the load on the motor by distributing mechanical forces, often resulting in quieter operation and improved durability. Understanding the specific gear ratios and mechanical advantages in your indirect drive setup is essential for optimizing performance and maintenance.

Key Differences Between Direct and Indirect Drive

Direct drive systems transmit power directly from the motor to the load, resulting in higher efficiency, reduced maintenance, and minimal energy loss, while indirect drive systems use intermediate components such as belts or gears, which can introduce slippage and require regular upkeep. Direct drives typically offer better precision and torque control due to the elimination of mechanical intermediary parts, whereas indirect drives provide greater flexibility in positioning and cost-effective solutions for lower power applications. Noise levels in direct drive systems are generally lower compared to indirect drives, which may produce additional noise due to belt tension and wear.

Efficiency Comparison: Direct vs Indirect Drive

Direct drive systems offer higher efficiency by eliminating intermediary components like belts or gears, resulting in reduced energy loss and smoother power transmission. Indirect drive systems experience greater mechanical friction and slippage, which decreases overall efficiency and increases maintenance requirements. In applications prioritizing energy savings and performance, direct drive is often preferred due to its superior mechanical efficiency.

Applications of Direct Drive Technology

Direct drive technology is widely utilized in precision applications such as robotics, CNC machines, and electric vehicles due to its high torque, reduced maintenance, and improved efficiency. Industries including aerospace, automation, and renewable energy rely on direct drive motors for their superior accuracy and reliability compared to indirect drive systems. This technology is also instrumental in medical equipment and conveyor systems where smooth, precise motion control is critical.

Uses and Advantages of Indirect Drive

Indirect drive systems are commonly used in applications requiring torque multiplication and speed reduction, such as automotive transmissions and industrial machinery. These systems leverage gears, belts, or chains to transfer power, offering the advantage of flexibility in positioning components and reducing the rotational speed for enhanced control. Your choice of indirect drive ensures improved mechanical advantage, adaptability to varying load conditions, and maintenance convenience.

Maintenance and Longevity: Which Is Better?

Direct drive systems require less maintenance due to fewer moving parts and lack of belts or gears, reducing wear and potential mechanical failures. Indirect drive mechanisms, relying on belts or gears, need regular inspections, adjustments, and replacements to maintain optimal performance. Your choice impacts longevity, with direct drive generally offering a longer lifespan and more reliable operation over time.

Cost Implications: Direct vs Indirect Drive

Direct drive systems typically have higher upfront costs due to advanced motor technology and precision components, but they offer lower maintenance expenses and better energy efficiency over time. Indirect drive systems generally feature lower initial investment but incur higher maintenance costs due to additional mechanical parts like belts or gears that wear out faster. When calculating total cost of ownership, direct drive solutions often prove more cost-effective in long-term industrial and automotive applications.

Choosing the Right Drive System for Your Needs

Direct drive systems offer higher efficiency, reduced maintenance, and better precision due to the motor being directly connected to the load, making them ideal for applications requiring accurate control and minimal downtime. Indirect drive systems, using gears, belts, or chains, provide greater flexibility in speed and torque adjustments, often at a lower initial cost but with increased wear and maintenance over time. Assessing your specific power requirements, space constraints, and long-term reliability needs will help you determine whether a direct or indirect drive system best suits your application.

Direct drive vs indirect drive Infographic

libmatt.com

libmatt.com