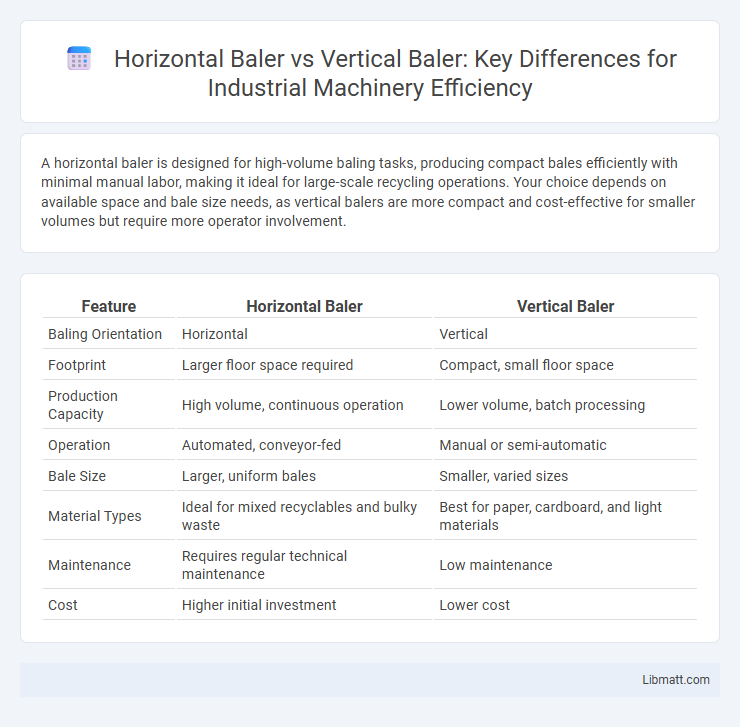

A horizontal baler is designed for high-volume baling tasks, producing compact bales efficiently with minimal manual labor, making it ideal for large-scale recycling operations. Your choice depends on available space and bale size needs, as vertical balers are more compact and cost-effective for smaller volumes but require more operator involvement.

Table of Comparison

| Feature | Horizontal Baler | Vertical Baler |

|---|---|---|

| Baling Orientation | Horizontal | Vertical |

| Footprint | Larger floor space required | Compact, small floor space |

| Production Capacity | High volume, continuous operation | Lower volume, batch processing |

| Operation | Automated, conveyor-fed | Manual or semi-automatic |

| Bale Size | Larger, uniform bales | Smaller, varied sizes |

| Material Types | Ideal for mixed recyclables and bulky waste | Best for paper, cardboard, and light materials |

| Maintenance | Requires regular technical maintenance | Low maintenance |

| Cost | Higher initial investment | Lower cost |

Introduction to Horizontal and Vertical Balers

Horizontal balers are industrial machines designed for continuous, high-volume baling, often used in large recycling facilities and manufacturing plants to compress materials like cardboard, plastics, and textiles into dense, manageable bales. Vertical balers, by contrast, operate with a vertical press mechanism and are ideal for smaller operations or businesses with limited space, efficiently compacting materials such as paper, cardboard, and plastics into smaller, uniform bales. The choice between horizontal and vertical balers depends on factors such as available space, bale size requirements, material throughput, and operational workflow.

Key Differences Between Horizontal and Vertical Balers

Horizontal balers are designed for high-volume waste processing, featuring a horizontal chamber that compresses materials into large, dense bales suitable for industrial use. Vertical balers, on the other hand, use a vertical chamber and are ideal for smaller-scale operations with limited space, allowing you to easily operate them manually or with minimal power. The key differences lie in bale size, production speed, and footprint, with horizontal balers offering greater efficiency for large waste streams and vertical balers providing convenience and cost-effectiveness for lighter, sporadic baling needs.

How Horizontal Balers Work

Horizontal balers compress materials by feeding waste horizontally into the compression chamber, where a hydraulic ram applies pressure to compact the material into dense bales. This process allows for continuous loading, making them ideal for high-volume recycling operations involving cardboard, plastics, and paper. Your facility can benefit from faster bale production and reduced manual labor compared to vertical balers, which require loading from the top and compress materials vertically.

How Vertical Balers Work

Vertical balers operate by placing recyclable materials into a chamber where a hydraulic ram compresses the waste vertically, creating dense, compact bales. The vertical compression mechanism maximizes space efficiency and allows for easy loading, making them ideal for small to medium-sized volumes of materials such as cardboard, paper, and plastics. These balers are designed to balance operational simplicity with effective compaction, reducing transportation costs and improving recycling facility workflow.

Capacity and Throughput Comparison

Horizontal balers typically offer higher capacity and throughput compared to vertical balers, processing larger volumes of materials continuously. Their design allows for faster cycle times and greater bale output, making them ideal for high-volume operations. Choosing the right baler depends on your material volume and space availability, as horizontal balers require more floor area but significantly increase productivity.

Space and Footprint Considerations

Horizontal balers require significantly more floor space due to their elongated design, making them ideal for high-volume operations with ample room. Vertical balers have a smaller footprint, occupying less space and fitting easily into tight areas, which suits facilities with limited floor space. Choosing between the two depends largely on available space and the volume of materials to be processed.

Operational Costs and Maintenance

Horizontal balers typically incur higher operational costs due to greater power consumption and the need for larger workspace, while vertical balers are more cost-effective with lower energy use and compact design. Maintenance for horizontal balers can be more intensive, requiring regular inspection of hydraulic systems and conveyor belts, whereas vertical balers demand simpler upkeep focused on manual loading mechanisms and fewer moving parts. Your choice impacts long-term expenses, as vertical balers generally offer reduced maintenance and operational costs ideal for smaller-scale applications.

Suitability for Different Materials

Horizontal balers are ideal for processing large volumes of bulky and heavy materials such as cardboard, plastic film, and textiles, providing efficient compaction for commercial and industrial recycling. Vertical balers excel in handling smaller quantities of various materials like paper, cardboard, and plastics, making them suitable for retail stores and small businesses with limited space. Material suitability depends on volume, type, and space constraints, with horizontal balers favoring high-capacity, continuous baling and vertical balers offering versatility for diverse, lower-volume waste streams.

Industry Applications: Which Baler Fits Your Needs?

Horizontal balers are ideal for high-volume industries such as recycling centers, manufacturing plants, and large warehouses where continuous, automated baling of materials like cardboard, plastics, and metals is required. Vertical balers suit smaller operations, retail stores, and offices with limited space and lower bale output needs, efficiently handling materials like paper, plastic film, and light cardboard. Selecting a baler depends on material volume, available floor space, and desired bale size, making horizontal balers suitable for heavy-duty, high-throughput applications and vertical balers perfect for compact, intermittent baling tasks.

Choosing the Right Baler for Your Business

Choosing the right baler for your business depends on your available space and volume of materials. Horizontal balers are ideal for high-volume operations with continuous waste output, offering faster processing and higher capacity. Vertical balers take up less floor space and work well for smaller businesses or those with intermittent waste generation, providing an efficient, cost-effective solution for compacting recyclables.

Horizontal baler vs vertical baler Infographic

libmatt.com

libmatt.com