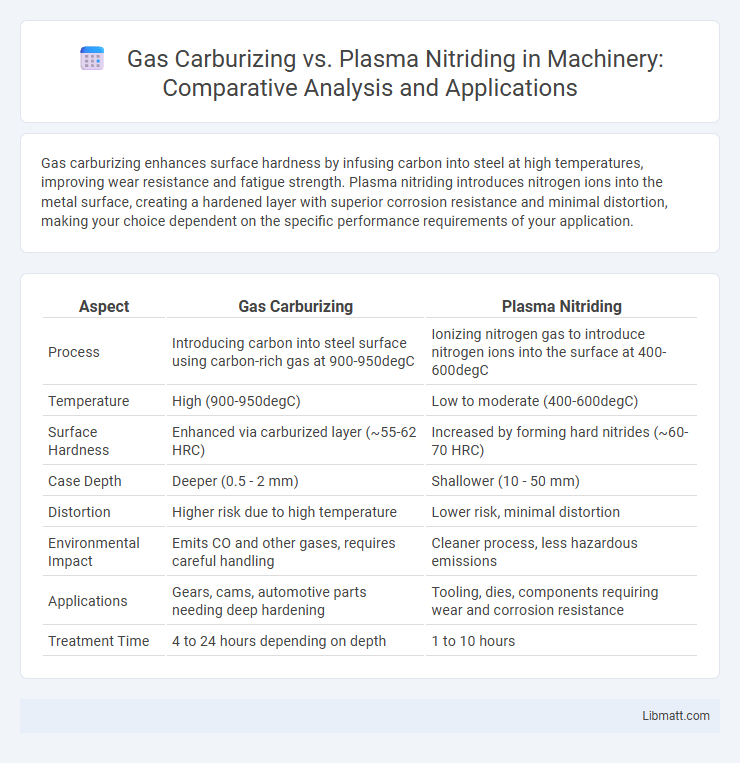

Gas carburizing enhances surface hardness by infusing carbon into steel at high temperatures, improving wear resistance and fatigue strength. Plasma nitriding introduces nitrogen ions into the metal surface, creating a hardened layer with superior corrosion resistance and minimal distortion, making your choice dependent on the specific performance requirements of your application.

Table of Comparison

| Aspect | Gas Carburizing | Plasma Nitriding |

|---|---|---|

| Process | Introducing carbon into steel surface using carbon-rich gas at 900-950degC | Ionizing nitrogen gas to introduce nitrogen ions into the surface at 400-600degC |

| Temperature | High (900-950degC) | Low to moderate (400-600degC) |

| Surface Hardness | Enhanced via carburized layer (~55-62 HRC) | Increased by forming hard nitrides (~60-70 HRC) |

| Case Depth | Deeper (0.5 - 2 mm) | Shallower (10 - 50 mm) |

| Distortion | Higher risk due to high temperature | Lower risk, minimal distortion |

| Environmental Impact | Emits CO and other gases, requires careful handling | Cleaner process, less hazardous emissions |

| Applications | Gears, cams, automotive parts needing deep hardening | Tooling, dies, components requiring wear and corrosion resistance |

| Treatment Time | 4 to 24 hours depending on depth | 1 to 10 hours |

Introduction to Surface Hardening Techniques

Gas carburizing and plasma nitriding are advanced surface hardening techniques used to enhance the wear resistance and fatigue strength of steel components. Gas carburizing involves diffusing carbon into the metal surface at high temperatures, creating a hard, wear-resistant outer layer while maintaining a tougher core. Plasma nitriding introduces nitrogen ions into the surface via a glow discharge, yielding a hardened case with improved corrosion resistance and dimensional stability, ideal for precision parts requiring uniform hardness.

Overview of Gas Carburizing

Gas carburizing is a thermal diffusion process that enriches the surface of steel with carbon by exposing it to a carbon-rich environment at high temperatures, typically between 900degC and 950degC. This method enhances surface hardness, wear resistance, and fatigue strength by forming a hard, carbon-enriched case while maintaining a tough core. Compared to plasma nitriding, gas carburizing offers deeper case depths, making it ideal for heavy-duty applications requiring significant surface hardening.

Overview of Plasma Nitriding

Plasma nitriding is a surface hardening process that introduces nitrogen ions into the material's surface using a glow discharge plasma, enhancing wear and corrosion resistance without altering the dimensions significantly. Unlike gas carburizing, which relies on carbon diffusion at high temperatures, plasma nitriding operates at lower temperatures, reducing thermal distortion and preserving mechanical properties. Your components benefit from improved fatigue strength and surface hardness, making plasma nitriding ideal for precision parts in aerospace, automotive, and tooling industries.

Key Process Differences

Gas carburizing uses a carbon-rich gas atmosphere to introduce carbon into the steel surface at high temperatures, enhancing hardness through case hardening. Plasma nitriding employs ionized nitrogen gas under low pressure to diffuse nitrogen into the steel, improving surface hardness and wear resistance without significant distortion. Unlike gas carburizing, plasma nitriding operates at lower temperatures and provides better control over case depth and uniformity.

Material Compatibility and Suitability

Gas carburizing effectively enhances the surface hardness of low-carbon steels and certain alloy steels by infusing carbon atoms into the material, making it suitable for components requiring improved wear resistance and fatigue strength. Plasma nitriding, on the other hand, is compatible with a broader range of materials, including stainless steels, titanium, and tool steels, by introducing nitrogen atoms to create a hardened surface without affecting the base material's dimensions. Your choice between these treatments depends on the specific alloy composition and desired mechanical properties, with plasma nitriding offering superior precision for parts sensitive to distortion.

Process Temperature and Cycle Time

Gas carburizing typically operates at higher temperatures ranging from 900degC to 950degC with cycle times between 8 to 24 hours, making it suitable for enhancing surface hardness and fatigue resistance of carbon steel parts. Plasma nitriding is performed at lower temperatures, usually between 400degC and 600degC, with shorter cycle times often lasting 6 to 24 hours, ideal for improving wear and corrosion resistance without affecting the core properties of your components. Choosing between these methods depends on your required surface characteristics and acceptable processing duration.

Surface Hardness and Case Depth

Gas carburizing typically achieves a deeper case depth, often ranging from 0.5 to 2.5 mm, with moderate surface hardness between 55-62 HRC, making it ideal for components requiring significant wear resistance beneath the surface. Plasma nitriding produces higher surface hardness, often exceeding 70 HRC, but with a shallower case depth usually less than 0.5 mm, providing superior fatigue strength and corrosion resistance. Choosing between these processes depends on whether your application demands deeper case hardening or enhanced surface hardness with minimal distortion.

Wear and Corrosion Resistance

Gas carburizing enhances surface hardness by introducing carbon into steel, significantly improving wear resistance in high-friction applications, but offers limited corrosion resistance. Plasma nitriding introduces nitrogen ions under plasma conditions, creating a hardened layer that provides excellent wear resistance alongside superior corrosion protection due to the formation of stable nitrides. Your choice depends on whether wear resistance alone or a combination of wear and corrosion resistance is the priority for the component's operating environment.

Environmental and Economic Considerations

Gas carburizing involves the use of hydrocarbon gases at high temperatures, leading to higher carbon emissions and increased energy consumption compared to plasma nitriding, which operates under low pressure and uses ionized nitrogen, resulting in reduced environmental impact. Plasma nitriding offers a more energy-efficient process with lower greenhouse gas emissions, translating into cost savings on fuel and regulatory compliance for your manufacturing operations. Investing in plasma nitriding technology can optimize your production costs while enhancing sustainability, aligning with modern environmental standards and economic goals.

Practical Applications and Industry Use Cases

Gas carburizing excels in automotive and heavy machinery industries by enhancing surface hardness and wear resistance of steel components like gears and crankshafts. Plasma nitriding is favored in aerospace and medical device sectors for its precise control, producing nitrided layers that improve fatigue strength and corrosion resistance without distortion. Your choice depends on the specific material requirements and performance goals in demanding industrial environments.

Gas carburizing vs plasma nitriding Infographic

libmatt.com

libmatt.com