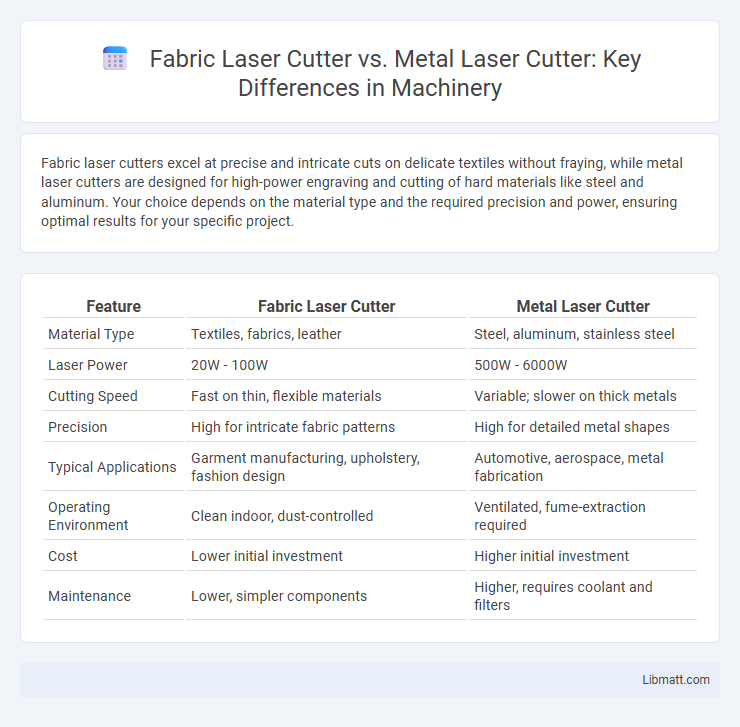

Fabric laser cutters excel at precise and intricate cuts on delicate textiles without fraying, while metal laser cutters are designed for high-power engraving and cutting of hard materials like steel and aluminum. Your choice depends on the material type and the required precision and power, ensuring optimal results for your specific project.

Table of Comparison

| Feature | Fabric Laser Cutter | Metal Laser Cutter |

|---|---|---|

| Material Type | Textiles, fabrics, leather | Steel, aluminum, stainless steel |

| Laser Power | 20W - 100W | 500W - 6000W |

| Cutting Speed | Fast on thin, flexible materials | Variable; slower on thick metals |

| Precision | High for intricate fabric patterns | High for detailed metal shapes |

| Typical Applications | Garment manufacturing, upholstery, fashion design | Automotive, aerospace, metal fabrication |

| Operating Environment | Clean indoor, dust-controlled | Ventilated, fume-extraction required |

| Cost | Lower initial investment | Higher initial investment |

| Maintenance | Lower, simpler components | Higher, requires coolant and filters |

Introduction to Laser Cutting Technologies

Fabric laser cutters use CO2 lasers to precisely cut textiles with clean edges and minimal heat damage, optimizing designs for fashion and upholstery industries. Metal laser cutters employ fiber or solid-state lasers capable of high-powered cutting and engraving on stainless steel, aluminum, and other metals, essential for automotive, aerospace, and manufacturing sectors. Both technologies leverage CNC systems for accuracy, but differ significantly in wavelength and power suited to their respective materials and applications.

Key Differences Between Fabric and Metal Laser Cutters

Fabric laser cutters use lower power settings and CO2 lasers to precisely cut or engrave textiles without burning or melting, while metal laser cutters employ high-powered fiber or CO2 lasers to cut through or etch metals like stainless steel and aluminum. Fabric cutters prioritize speed and fine detail for soft, flexible materials, whereas metal cutters focus on durability, thickness penetration, and heat management for rigid, conductive surfaces. The software and hardware components differ significantly to optimize cutting parameters, with fabric laser cutters designed for delicate handling and metal cutters engineered for heavy-duty industrial applications.

Types of Materials Each Cutter Can Process

Fabric laser cutters excel in processing organic materials such as cotton, silk, polyester, and nylon, delivering precise cuts and engravings on textiles and fabrics. Metal laser cutters are designed to handle a range of metals including steel, aluminum, brass, and titanium, providing high-power laser beams to cut or engrave hard, conductive materials efficiently. Each cutter is optimized for its material category, ensuring clean edges and minimal material distortion tailored to the physical properties of fabric or metal substrates.

Laser Power and Precision Comparison

Fabric laser cutters typically operate with lower laser power ranging from 30 to 150 watts, ideal for cutting delicate textiles with high precision and minimal material damage. Metal laser cutters use significantly higher laser power, often exceeding 1000 watts, to effectively cut through dense metals with exceptional accuracy and edge quality. The precision of fabric cutters suits intricate patterns, while metal cutters emphasize power for clean, precise cuts on tough metal surfaces.

Speed and Efficiency in Production

Fabric laser cutters operate at high speeds suitable for thin, flexible materials, enabling rapid production cycles with minimal waste, ideal for textile manufacturing. Metal laser cutters, while slower due to the density and thickness of metals, offer precise, efficient cutting that reduces the need for secondary processing, enhancing overall production efficiency. Your choice between the two should consider the specific material demands and production volume to optimize speed and operational efficiency.

Cost Considerations for Fabric vs Metal Laser Cutters

Fabric laser cutters generally have lower upfront costs compared to metal laser cutters due to simpler technology and less powerful laser sources required for cutting textiles. Metal laser cutters demand higher investment for advanced fiber or CO2 lasers capable of piercing through tough metals, often coupled with specialized cooling and ventilation systems. You should weigh your material focus and production volume carefully, as operating costs and maintenance expenses tend to be higher for metal laser cutting machines due to their complexity and energy consumption.

Maintenance and Operational Requirements

Fabric laser cutters demand regular cleaning of lenses and mirrors to maintain precision, with frequent checks to prevent fabric residue buildup that can impair functionality. Metal laser cutters require more intensive maintenance due to higher power usage, including cooling system upkeep and periodic nozzle replacement to ensure consistent cutting quality. Your choice impacts operational costs, as fabric cutters generally have lower maintenance expenses compared to the more complex requirements of metal laser systems.

Safety Features and Best Practices

Fabric laser cutters incorporate advanced safety features such as enclosed cutting areas and smoke extraction systems to protect users from flammable fibers and airborne particles. Metal laser cutters prioritize robust cooling systems, interlocks, and protective shielding to manage intense heat and prevent accidental exposure to high-powered laser beams. To maximize safety, you should always follow manufacturer guidelines, wear appropriate protective gear, and ensure proper ventilation regardless of the material being cut.

Ideal Applications for Fabric and Metal Laser Cutters

Fabric laser cutters excel in precision cutting and intricate designs for textiles, making them ideal for apparel, upholstery, and custom fabric patterns. Metal laser cutters deliver powerful, high-precision cutting suitable for industrial applications like automotive parts, aerospace components, and heavy machinery fabrication. Choosing the right laser cutter depends on your material type, required detail, and production scale to optimize efficiency and output quality.

Choosing the Right Laser Cutter for Your Needs

Selecting the right laser cutter depends on the material and project requirements, where fabric laser cutters excel in precision for textiles, offering clean cuts and intricate designs without fraying edges. Metal laser cutters provide high power and durability, capable of cutting thick and hard metals with excellent accuracy and minimal heat distortion. Assessing factors such as material thickness, laser power, cutting speed, and intended application ensures optimal performance and cost-efficiency for either fabric or metal laser cutting tasks.

Fabric laser cutter vs metal laser cutter Infographic

libmatt.com

libmatt.com