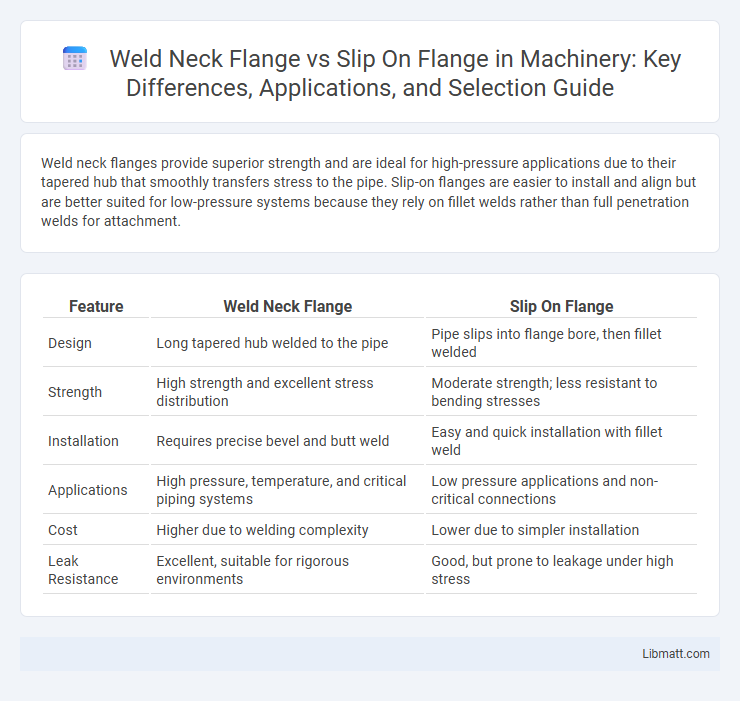

Weld neck flanges provide superior strength and are ideal for high-pressure applications due to their tapered hub that smoothly transfers stress to the pipe. Slip-on flanges are easier to install and align but are better suited for low-pressure systems because they rely on fillet welds rather than full penetration welds for attachment.

Table of Comparison

| Feature | Weld Neck Flange | Slip On Flange |

|---|---|---|

| Design | Long tapered hub welded to the pipe | Pipe slips into flange bore, then fillet welded |

| Strength | High strength and excellent stress distribution | Moderate strength; less resistant to bending stresses |

| Installation | Requires precise bevel and butt weld | Easy and quick installation with fillet weld |

| Applications | High pressure, temperature, and critical piping systems | Low pressure applications and non-critical connections |

| Cost | Higher due to welding complexity | Lower due to simpler installation |

| Leak Resistance | Excellent, suitable for rigorous environments | Good, but prone to leakage under high stress |

Introduction to Flange Types

Weld neck flanges feature a long tapered hub that provides excellent stress distribution and resistance to dishing, making them ideal for high-pressure and high-temperature applications. Slip-on flanges, characterized by their ease of alignment and welding, are typically used in low-pressure systems and allow the pipe to slip into the flange bore before being welded. Both flange types serve critical roles in piping systems but differ significantly in installation complexity, strength, and suitable operating conditions.

Weld Neck Flange: Key Features

Weld neck flanges feature a long tapered hub that gradually transitions thickness, providing excellent stress distribution and resistance to dishing under high pressure. This design ensures a strong, leak-proof connection by requiring welding around the entire flange neck, making it ideal for high-pressure and high-temperature applications. Your piping system benefits from enhanced durability and reduced fatigue with weld neck flanges compared to slip on flanges.

Slip On Flange: Key Features

Slip on flange features a simple design that allows the pipe to slide into the flange before being welded, providing ease of alignment and installation. Its lower cost and suitability for low-pressure applications make it a popular choice, especially in systems where frequent disassembly is needed. You'll benefit from its versatility and quick installation in piping systems requiring moderate temperature and pressure resistance.

Installation Process Comparison

Weld neck flanges require precise alignment for butt welding to the pipe, ensuring high strength and leak resistance, especially under high pressure or stress conditions. Slip-on flanges slide over the pipe and are fillet welded, offering easier installation but lower strength and pressure ratings compared to weld neck flanges. The installation of weld neck flanges demands skilled labor and careful preparation, while slip-on flanges are more user-friendly for quick assembly and lower-cost projects.

Strength and Durability Differences

Weld neck flanges offer superior strength and durability due to their tapered hub, which provides better stress distribution in high-pressure and high-temperature applications. Slip on flanges, while easier to install, have lower strength because they are not butt-welded but rather slipped over the pipe and fillet welded, making them less suitable for critical or heavy-duty conditions. Your choice should consider the operational pressures and durability requirements to ensure optimal performance and safety.

Pressure and Temperature Capabilities

Weld neck flanges offer superior pressure and temperature capabilities due to their reinforced construction and gradual transition from flange to pipe, making them ideal for high-stress applications. Slip on flanges are better suited for lower pressure and temperature environments because their design involves sliding over the pipe, resulting in less strength and resistance. Understanding these differences ensures your piping system maintains integrity under specific operational conditions.

Cost Analysis: Weld Neck vs Slip On

Weld neck flanges typically incur higher initial costs due to their complex manufacturing and installation processes, requiring skilled welding and more precise alignment. Slip-on flanges offer a cost-effective alternative with simpler design and easier installation, reducing labor and time expenses. Your choice depends on budget constraints balanced against long-term durability and stress-handling requirements in piping systems.

Common Applications for Each Flange

Weld neck flanges are commonly used in high-pressure and high-temperature applications such as oil and gas pipelines, chemical processing, and power plants due to their strong and leak-proof connection. Slip-on flanges are typically employed in low-pressure systems and are preferred for their ease of installation in water treatment, HVAC, and plumbing industries. Both flange types serve crucial roles in ensuring secure pipeline connections while catering to different operational demands and safety standards.

Pros and Cons of Weld Neck Flange

Weld neck flanges provide superior strength and leak resistance due to their tapered hub, which distributes stress evenly and is ideal for high-pressure and high-temperature applications. Their main drawbacks include higher manufacturing costs and more complex installation compared to slip-on flanges, requiring precise alignment and skilled welding. Despite this, weld neck flanges offer enhanced durability and longevity, making them the preferred choice for critical piping systems.

Pros and Cons of Slip On Flange

Slip on flanges are easier to install and cost-effective, allowing you to quickly align piping systems with minimal welding requirements. However, they offer lower pressure ratings and weaker mechanical strength compared to weld neck flanges, making them less suitable for high-pressure or critical applications. Their susceptibility to leakage and reduced durability under high stress limits their use in demanding industrial environments.

Weld neck flange vs slip on flange Infographic

libmatt.com

libmatt.com