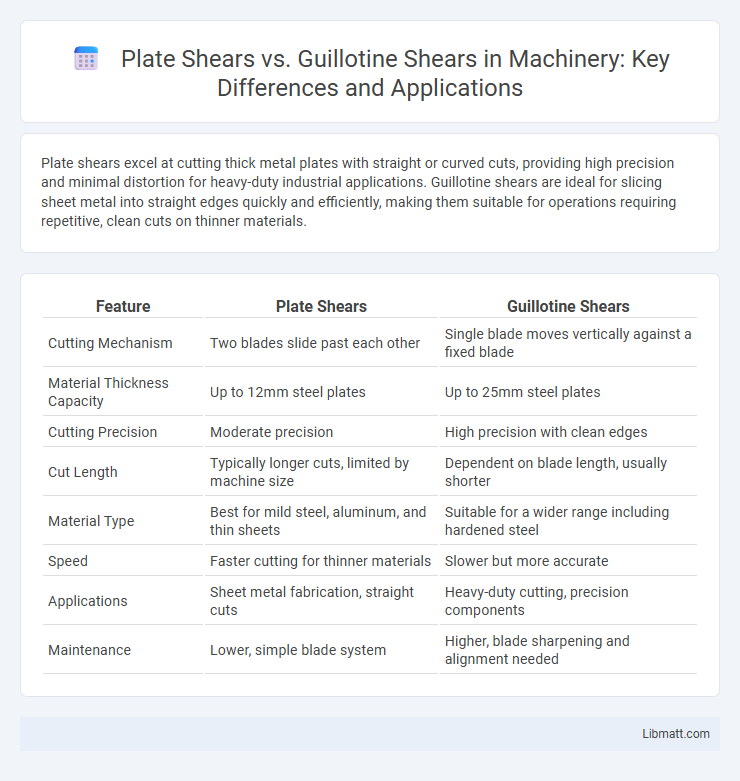

Plate shears excel at cutting thick metal plates with straight or curved cuts, providing high precision and minimal distortion for heavy-duty industrial applications. Guillotine shears are ideal for slicing sheet metal into straight edges quickly and efficiently, making them suitable for operations requiring repetitive, clean cuts on thinner materials.

Table of Comparison

| Feature | Plate Shears | Guillotine Shears |

|---|---|---|

| Cutting Mechanism | Two blades slide past each other | Single blade moves vertically against a fixed blade |

| Material Thickness Capacity | Up to 12mm steel plates | Up to 25mm steel plates |

| Cutting Precision | Moderate precision | High precision with clean edges |

| Cut Length | Typically longer cuts, limited by machine size | Dependent on blade length, usually shorter |

| Material Type | Best for mild steel, aluminum, and thin sheets | Suitable for a wider range including hardened steel |

| Speed | Faster cutting for thinner materials | Slower but more accurate |

| Applications | Sheet metal fabrication, straight cuts | Heavy-duty cutting, precision components |

| Maintenance | Lower, simple blade system | Higher, blade sharpening and alignment needed |

Introduction to Plate Shears and Guillotine Shears

Plate shears and guillotine shears are essential tools used in metal fabrication for cutting sheet and plate materials. Plate shears utilize a pair of blades moving parallel to each other, providing straight cuts ideal for thicker materials, while guillotine shears employ a single blade descending vertically to produce precise, burr-free cuts in thinner sheets. Understanding the differences between these machines helps optimize your cutting process for efficiency and material quality.

Understanding Plate Shears: Key Features

Plate shears are industrial machines designed to cut thick metal plates with precision, using a pair of blades in a scissor-like motion to create clean, straight cuts. They typically feature a robust frame, adjustable blade clearance, and hydraulic or mechanical power systems to handle high cutting forces efficiently. High versatility in thickness capacity and the ability to produce minimal burrs make plate shears essential in heavy fabrication and metalworking industries.

Guillotine Shears: Design and Functionality

Guillotine shears feature a fixed blade paired with a moving blade that descends vertically to cut metal plates with precise straight lines. The design includes a robust frame to withstand high cutting forces, a mechanical or hydraulic drive system for blade movement, and adjustable back gauges for accurate length control. This configuration enables efficient shearing of thick metal sheets with clean-edge results, making guillotine shears ideal for heavy-duty industrial metal fabrication.

Comparing Cutting Mechanisms

Plate shears use a scissor-like cutting action with two blades moving past each other to slice through metal, providing clean and precise cuts on thick materials. Guillotine shears operate with a single blade that moves vertically down onto a fixed blade, leveraging a powerful shear force suitable for straight cuts on sheet metal. Your choice depends on the type and thickness of material, with plate shears excelling in heavier, thicker plates and guillotine shears more efficient for thinner sheets.

Material Compatibility and Thickness Range

Plate shears primarily handle thicker, heavy-duty materials such as steel plates up to 25 mm thick, offering precise cutting for high-strength alloys and structural metals. Guillotine shears excel with thinner sheets, typically ranging from 0.5 to 6 mm, effectively processing materials like stainless steel, aluminum, and galvanized steel with clean, straight cuts. Material compatibility favors plate shears for robust, high-tensile metals, while guillotine shears suit lighter gauge metals requiring fine edge quality.

Precision and Quality of Cuts

Plate shears deliver high precision and clean cuts by using a straight blade to slice through thick metal plates with minimal deformation. Guillotine shears, while effective for quick cuts, often produce slightly rougher edges and minor distortions due to their angled blade motion. For applications demanding superior edge quality and consistent dimensions, plate shears are the preferred choice in metal fabrication industries.

Efficiency and Operational Speed

Plate shears deliver higher efficiency and faster operational speed by using parallel blades that provide smooth, continuous cutting ideal for thicker metal sheets. Guillotine shears operate with a single straight blade moving downward to cut, which can be slower and less suitable for rapid production runs but offers precise cuts. Your choice depends on the required throughput and material thickness, with plate shears generally preferred for faster, high-volume operations.

Maintenance and Durability Considerations

Plate shears require regular blade sharpening and lubrication to maintain cutting precision, while guillotine shears demand more frequent blade replacement due to their more intense shearing action. The durability of plate shears generally surpasses guillotine shears in heavy-duty applications because of their robust construction and lower wear rates. You should consider maintenance accessibility and long-term operational costs when choosing between these shearing tools.

Safety Features and Operator Experience

Plate shears typically incorporate enclosed blade guards and emergency stop mechanisms, enhancing operator safety compared to guillotine shears, which may have more exposed cutting areas. The controlled, linear motion of plate shears reduces the risk of accidental injury and provides smoother cuts, improving your overall handling experience. Operator comfort is further supported in plate shears with ergonomic controls and vibration dampening, whereas guillotine shears often require more manual force and skill to operate safely.

Choosing the Right Shear for Your Application

Plate shears offer high precision and clean cuts ideal for thick metal sheets, making them suitable for heavy-duty fabrication tasks and structural steel cutting. Guillotine shears excel in fast, straight-line cuts on thinner materials, providing efficiency in volume production and sheet metal processing. Selecting the right shear depends on material thickness, production speed requirements, and the desired cut quality for applications in industries like automotive, aerospace, and construction.

Plate shears vs guillotine shears Infographic

libmatt.com

libmatt.com