Face milling primarily removes material from the surface of a workpiece using the cutter's face, producing a smooth finish, while peripheral milling cuts along the material's edge for creating slots or contours. Your choice depends on the desired surface finish and the specific geometry needed for the machining task.

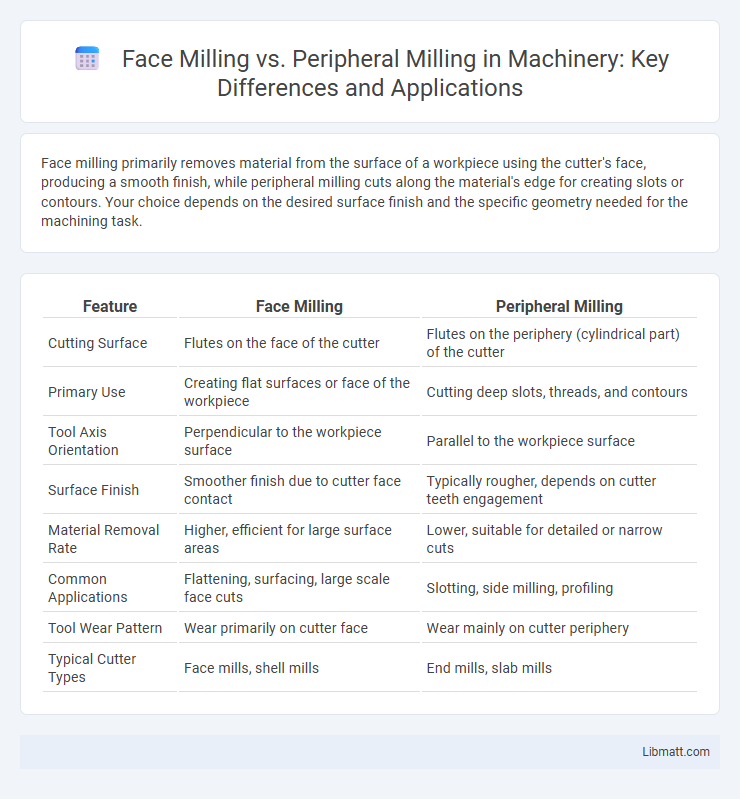

Table of Comparison

| Feature | Face Milling | Peripheral Milling |

|---|---|---|

| Cutting Surface | Flutes on the face of the cutter | Flutes on the periphery (cylindrical part) of the cutter |

| Primary Use | Creating flat surfaces or face of the workpiece | Cutting deep slots, threads, and contours |

| Tool Axis Orientation | Perpendicular to the workpiece surface | Parallel to the workpiece surface |

| Surface Finish | Smoother finish due to cutter face contact | Typically rougher, depends on cutter teeth engagement |

| Material Removal Rate | Higher, efficient for large surface areas | Lower, suitable for detailed or narrow cuts |

| Common Applications | Flattening, surfacing, large scale face cuts | Slotting, side milling, profiling |

| Tool Wear Pattern | Wear primarily on cutter face | Wear mainly on cutter periphery |

| Typical Cutter Types | Face mills, shell mills | End mills, slab mills |

Introduction to Face Milling and Peripheral Milling

Face milling primarily removes material from the surface of a workpiece using a cutting tool with its axis perpendicular to the surface, ideal for producing flat surfaces with high efficiency. Peripheral milling involves cutting along the outer edge or periphery of the rotating tool, typically used for creating slots, grooves, and complex contours with enhanced precision. Your choice between face milling and peripheral milling depends on the desired surface finish, shape, and the specific machining application requirements.

Key Differences Between Face and Peripheral Milling

Face milling primarily removes material from the surface of the workpiece using the cutter's face, resulting in a flat finish, while peripheral milling cuts along the workpiece edge with the cutter's circumference, ideal for creating slots and contours. Face milling tools have a larger diameter and more cutting edges, offering higher material removal rates and surface finish quality compared to peripheral milling cutters. Peripheral milling provides greater depth control and is better suited for intricate profiles, whereas face milling excels in achieving flat surfaces efficiently.

Tool Geometry and Cutter Design

Face milling utilizes cutters with multiple teeth placed on the cutter face, allowing high material removal rates on flat surfaces, whereas peripheral milling features cutters with teeth along the circumference for deeper cuts and contouring. The tool geometry in face milling typically includes a large diameter and flat cutters for efficient surface finish, while peripheral milling cutters are narrower with complex tooth profiles optimized for side cutting. Your choice of tool depends on the required surface finish, depth of cut, and part geometry, making cutter design crucial for milling efficiency and accuracy.

Cutting Action and Surface Generation

Face milling primarily removes material with the cutter's end face, producing a flat surface ideal for large, smooth finishes, while peripheral milling engages the cutter's outer edges to cut along the workpiece's length, making it suitable for detailed contour shaping. The cutting action in face milling results in a thinner chip with a lower cutting force, enhancing surface finish quality and reducing tool wear. Your choice between face and peripheral milling impacts surface generation, with face milling optimizing flat, wide surfaces and peripheral milling providing precise, textured edges and grooves.

Material Removal Rate Comparison

Face milling achieves higher material removal rates than peripheral milling due to its larger cutter diameter engaging the entire workpiece surface in a single pass. Peripheral milling engages only the cutter's periphery, resulting in lower cutting volume and slower material removal. The increased contact area and cutting depth in face milling optimize efficiency for heavy machining applications.

Surface Finish and Quality

Face milling produces a superior surface finish by cutting with the tool's face, enabling multiple cutting edges to engage simultaneously, which results in smoother and more uniform surfaces. Peripheral milling, engaging the cutter's circumference, is ideal for machining deeper slots but may leave visible tool marks and a rougher finish due to the single cutting point contact. Your choice between face and peripheral milling directly impacts the quality of the machined surface, with face milling offering enhanced precision and finish quality for critical applications.

Applications of Face Milling

Face milling is primarily used for creating flat surfaces, large material removal, and finishing work on wide, flat areas of a workpiece. It is ideal for machining surfaces that require high accuracy and fine finishes, such as engine blocks, machine beds, and large metal plates. Your projects benefit from face milling when precision and surface quality are critical in producing smooth, even surfaces across extensive areas.

Applications of Peripheral Milling

Peripheral milling is primarily used for creating deep slots, grooves, and flat surfaces on workpieces where axial depth of cut is critical. It is ideal for machining parts with complex profiles, such as gear teeth and keyways, due to its ability to produce accurate, precise cuts along the periphery of the cutter. Its applications extend to heavy-duty cutting in industries like automotive and aerospace, where high material removal rates and consistent surface finish are essential.

Tool Selection Criteria

Tool selection criteria for face milling prioritize large-diameter, multi-tooth cutters with a robust design to maximize surface finish and material removal rates. Peripheral milling demands tools with smaller diameters and replaceable inserts to handle deeper cuts and higher feed rates, optimizing edge strength for efficient chip formation. Material properties and desired surface quality guide the choice between carbide-tipped or high-speed steel tools in both milling operations.

Choosing the Right Milling Method for Your Project

Face milling removes material from the surface of a workpiece using the cutter's face, ideal for creating flat surfaces and large, smooth finishes. Peripheral milling engages the cutter's edge, making it better suited for producing grooves, slots, or complex profiles along the workpiece's periphery. Your project's requirements for surface finish, geometry, and machining speed will guide the choice between face milling and peripheral milling to optimize efficiency and quality.

Face milling vs peripheral milling Infographic

libmatt.com

libmatt.com