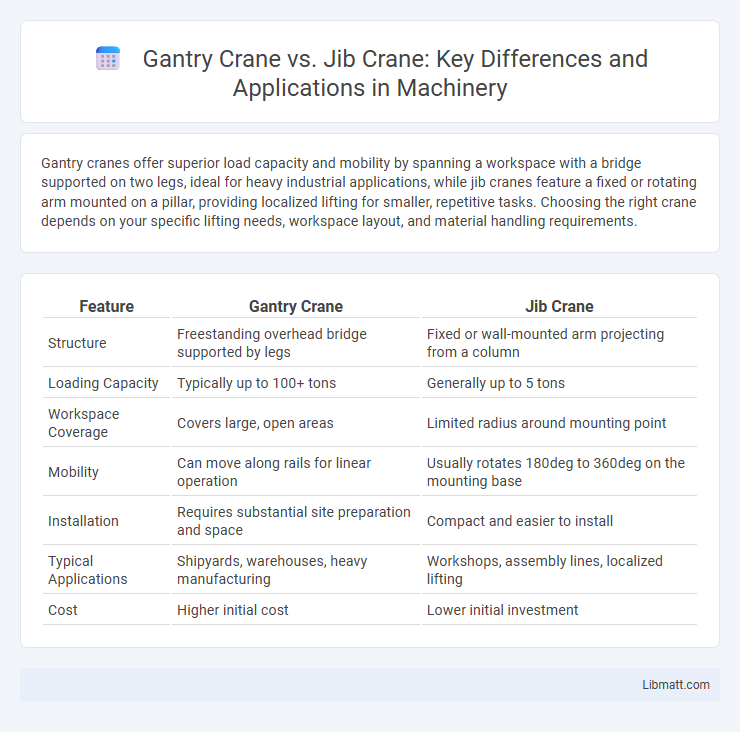

Gantry cranes offer superior load capacity and mobility by spanning a workspace with a bridge supported on two legs, ideal for heavy industrial applications, while jib cranes feature a fixed or rotating arm mounted on a pillar, providing localized lifting for smaller, repetitive tasks. Choosing the right crane depends on your specific lifting needs, workspace layout, and material handling requirements.

Table of Comparison

| Feature | Gantry Crane | Jib Crane |

|---|---|---|

| Structure | Freestanding overhead bridge supported by legs | Fixed or wall-mounted arm projecting from a column |

| Loading Capacity | Typically up to 100+ tons | Generally up to 5 tons |

| Workspace Coverage | Covers large, open areas | Limited radius around mounting point |

| Mobility | Can move along rails for linear operation | Usually rotates 180deg to 360deg on the mounting base |

| Installation | Requires substantial site preparation and space | Compact and easier to install |

| Typical Applications | Shipyards, warehouses, heavy manufacturing | Workshops, assembly lines, localized lifting |

| Cost | Higher initial cost | Lower initial investment |

Introduction to Gantry and Jib Cranes

Gantry cranes and jib cranes both serve critical roles in material handling, with gantry cranes featuring a bridge supported by legs that move on wheels or rails, ideal for lifting heavy loads across wide spans. Jib cranes consist of a horizontal arm attached to a vertical mast, providing flexible rotation and efficient handling in confined spaces. Your choice depends on workspace requirements, load capacity, and maneuverability needs.

Key Differences Between Gantry and Jib Cranes

Gantry cranes feature a bridge supported by two or more legs running on a fixed runway or ground rails, allowing heavy load movement across large areas, while jib cranes have a horizontal arm fixed to a wall or vertical mast, offering limited rotation and reach. Gantry cranes handle larger capacities and are suitable for outdoor and heavy industrial applications, whereas jib cranes serve smaller loads and are ideal for localized lifting tasks in workshops or warehouses. The structural design differences impact their installation costs, operational flexibility, and space requirements.

Structural Design Comparison

Gantry cranes feature a robust framework with a bridge supported by two or more legs running on fixed rails, enabling heavy load lifting over large areas and offering superior stability for outdoor environments. Jib cranes consist of a horizontal arm (jib) mounted on a vertical mast or wall, allowing for localized lifting within a limited radius and optimized for compact spaces with lighter load capacities. The gantry crane's structural design supports extensive reach and high load capacity, whereas the jib crane prioritizes flexibility and space efficiency in smaller operational settings.

Load Capacity and Performance

Gantry cranes typically offer higher load capacities, ranging from a few tons up to several hundred tons, making them ideal for heavy-duty lifting and large-scale industrial applications. Jib cranes generally handle lighter loads, often between 0.5 to 5 tons, suited for repetitive, localized tasks within smaller workspaces. Your choice between these cranes should consider specific load requirements and workspace size to maximize operational performance and safety.

Installation and Space Requirements

Gantry cranes require significant floor space and overhead clearance due to their freestanding structure and large spans, making them suitable for outdoor or spacious industrial environments. Jib cranes have a more compact installation process, often mounted to walls or floors, which conserves valuable space and fits well in smaller or confined areas. Your choice between the two depends on the spatial constraints and the specific lifting needs of your facility.

Mobility and Flexibility

Gantry cranes provide superior mobility and flexibility by operating on rails or wheels, allowing them to cover large work areas and handle heavy loads with ease. Jib cranes, fixed to a single point or wall, offer limited range but excel in environments requiring precise, repetitive lifting within a confined space. Your choice depends on whether you need extensive movement or targeted lifting capabilities for efficient workflow.

Cost and Maintenance Considerations

Gantry cranes typically have higher initial costs due to their larger structure and increased load capacity compared to jib cranes. Maintenance expenses for gantry cranes tend to be greater because of more complex components like wheels, rails, and motors, leading to frequent inspections and repairs. In contrast, jib cranes offer lower installation and upkeep costs suited for smaller-scale operations with less demanding lifting requirements.

Typical Applications for Gantry Cranes

Gantry cranes are commonly used in heavy-duty applications such as shipyards, construction sites, and large warehouses where lifting and moving bulky or heavy materials is required. These cranes are ideal for outdoor use and can span large distances, making them suitable for loading and unloading cargo from trucks or trains. Your choice of gantry crane can enhance efficiency in environments demanding high lifting capacity and mobility.

Typical Applications for Jib Cranes

Jib cranes are commonly used in manufacturing plants, warehouses, and workshops for lifting and moving moderate-weight loads within a restricted radius. They excel in tasks requiring precise material handling, such as loading and unloading machines, assembly processes, and maintenance work. Their design allows for efficient operation in confined spaces where overhead crane installation is impractical.

Choosing the Right Crane for Your Needs

Selecting the right crane depends on the scope and scale of your lifting tasks; gantry cranes offer robust support for heavy loads and wide coverage in outdoor or large workshop environments. Jib cranes excel in confined spaces, providing precise maneuverability and localized lifting for assembly lines or smaller workstations. Prioritize load capacity, workspace layout, and portability to ensure optimal efficiency and safety in material handling operations.

Gantry crane vs jib crane Infographic

libmatt.com

libmatt.com